- 您现在的位置:买卖IC网 > PDF目录17729 > U2K110CG100FB-T (Taiyo Yuden)CAP ARRAY 2CH 10PF 50V 0504 PDF资料下载

参数资料

| 型号: | U2K110CG100FB-T |

| 厂商: | Taiyo Yuden |

| 文件页数: | 15/16页 |

| 文件大小: | 0K |

| 描述: | CAP ARRAY 2CH 10PF 50V 0504 |

| 标准包装: | 10 |

| 电容: | 10pF |

| 电压 - 额定: | 50V |

| 电介质材料: | 陶瓷 |

| 电容器数量: | 2 |

| 电路类型: | 隔离 |

| 温度系数: | C0G,NP0 |

| 容差: | ±10% |

| 安装类型: | 表面贴装 |

| 封装/外壳: | 0504(1210 公制) |

| 尺寸/尺寸: | 0.054" L x 0.039" W(1.37mm x 1.00mm) |

| 高度 - 座高(最大): | 0.024"(0.60mm) |

| 包装: | 剪切带 (CT) |

| 其它名称: | 587-1025-1 |

�� �

�

�

�■� PRECAUTIONS�

�Precautions� on� the� use� of� Multilayer� Ceramic� Capacitors�

�4. Soldering�

�◆� Selection� of� Flux�

�Since� ?ux� may� have� a� signi?cant� effect� on� the� performance� of� capacitors,� it� is� necessary� to� verify� the� following� conditions� prior� to� use;�

�(� 1� )� Flux� used� shall� be� less� than� or� equal� to� 0.1� wt%� (� in� CI� equivalent� )� of� halogenated� content.� Flux� having� a� strong� acidity� content� shall� not� be� applied.�

�(� 2� )� When� shall� capacitors� are� soldered� on� boards,� the� amount� of� ?ux� applied� shall� be� controlled� at� the� optimum� level.�

�(� 3� )� When� water-soluble� ?ux� is� used,� special� care� shall� be� taken� to� properly� clean� the� boards.�

�?� Cooling� :� The� temperature� difference� between� the� capacitors� and� cleaning� process� shall� not� be� greater� than� 100� ℃� .�

�Precautions�

�◆� Soldering�

�Temperature,� time,� amount� of� solder,� etc.� shall� be� set� in� accordance� with� their� recommended� conditions.�

�Sn-Zn� solder� paste� can� adversely� affect� MLCC� reliability.�

�Please� contact� us� prior� to� usage� of� Sn-Zn� solder.�

�◆� Selection� of� Flux�

�1-1.� When� too� much� halogenated� substance� (� Chlorine,� etc.� )� content� is� used� to� activate� ?ux,� or� highly� acidic� ?ux� is� used,� it� may� lead� to� corrosion� of� terminal� elec-�

�trodes� or� degradation� of� insulation� resistance� on� the� surfaces� of� the� capacitors.�

�1-2.� Flux� is� used� to� increase� solderability� in� wave� soldering.� However� if� too� much� ?ux� is� applied,� a� large� amount� of� ?ux� gas� may� be� emitted� and� may� adversely� affect�

�the� solderability.� To� minimize� the� amount� of� ?ux� applied,� it� is� recommended� to� use� a� ?ux-bubbling� system.�

�1-3.� Since� the� residue� of� water-soluble� ?ux� is� easily� dissolved� in� moisture� in� the� air,� the� residues� on� the� surfaces� of� capacitors� in� high� humidity� conditions� may� cause�

�a� degradation� of� insulation� resistance� and� reliability� of� the� capacitors.� Therefore,� the� cleaning� methods� and� the� capability� of� the� machines� used� shall� also� be�

�considered� carefully� when� water-soluble� ?ux� is� used.�

�◆� Soldering�

�?� Ceramic� chip� capacitors� are� susceptible� to� thermal� shock� when� exposed� to� rapid� or� concentrated� heating� or� rapid� cooling.�

�as�

�?� Therefore,� the� soldering� must� be� conducted� with� great� care� so� 300� to� prevent� malfunction� of� the� components� due� to� excessive� thermal� shock.�

�Peak� 260� ℃� Max.�

�?� Preheating� :� Capacitors� shall� be� preheated� suf?ciently,� and� the� temperature� difference� between� the� capacitors� and� solder� shall� be� within� 100� to� 130� ℃� .�

�Within� 10sec.�

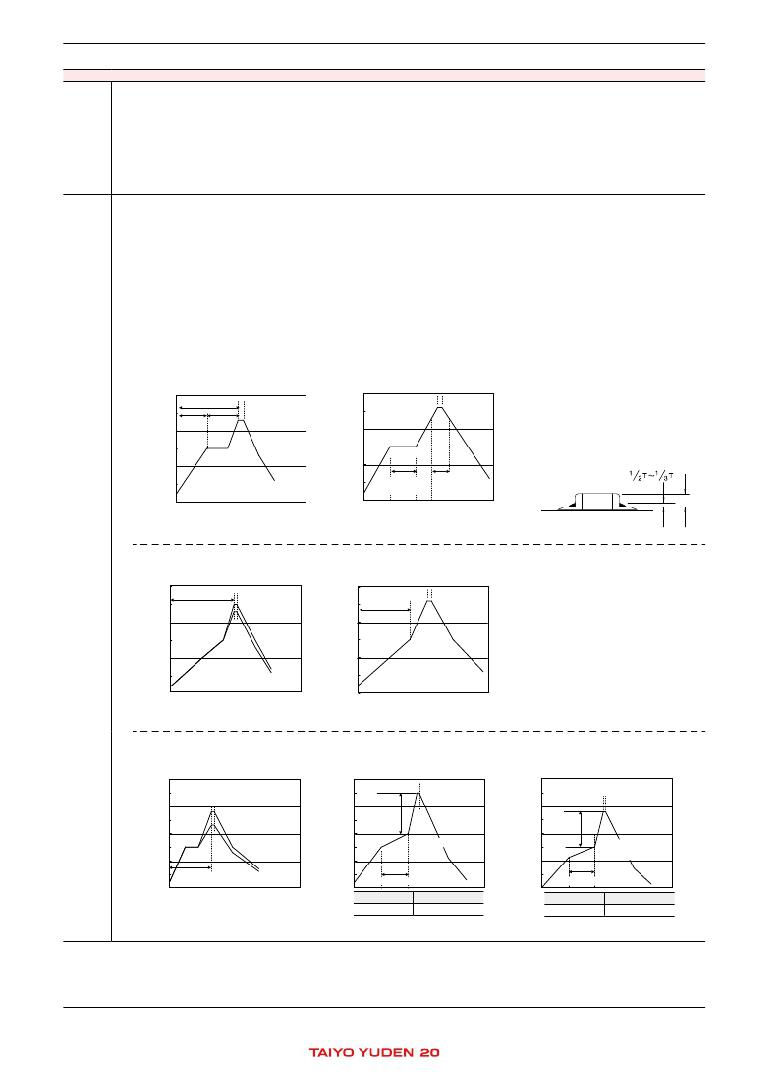

�[� Re?ow� soldering� ]�

�【� Recommended� conditions� for� eutectic� soldering� 】�

�200�

�Slow�

�cooling�

�【� Recommended� condition� for� Pb-free� soldering� 】�

�Slow� cooling�

�cooling�

�100�

�200� 60sec.� Min.�

�Heating� above�

�300�

�300�

�200�

�200�

�Preheating�

�60sec.� 60sec.�

�Min.� Min.�

�Peak� 260� ℃� Max.�

�230� ℃�

�Within� 10sec.�

�Within� 10� sec.�

�Slow�

�cooling�

�300�

�0�

�Preheating� 150� ℃�

�Peak� 260� ℃� Max.�

�Within� 10sec.�

�230� ℃�

�40sec.� Max.�

�Slow�

�cooling�

�100�

�100�

�Peak� 260� ℃� Max.� 100� 230� ~� 250� ℃�

�Preheating� 150� ℃�

�Heating� above� Within� 3sec.�

�230� ℃�

�230� ℃�

�Preheating� 150� ℃�

�60sec.� Min.� 120sec.� Min.� 230� ℃�

�200� 0� 0�

�40sec.� Max.�

�0�

�Slow� cooling�

�Caution�

�①� The� 300�

�ideal� condition� is� to� have� solder� mass� (� ?llet� )� controlled� 300� 1/2� to� 1/3� of� the� thickness� of� a� capacitor.�

�to�

�②� Because� excessive� dwell� times� can� adversely� affect� solderability,� soldering� duration� 230� ~� 250� ℃�

�100� 230� ~� 250� ℃� 100�

�close� to� recommended� times� Within� possible.�

�as�

�Within� 3sec.�

�Heating� above�

�Preheating�

�120sec.� Min.� 150� ℃� 230� ℃�

�200�

�60sec.� Min.�

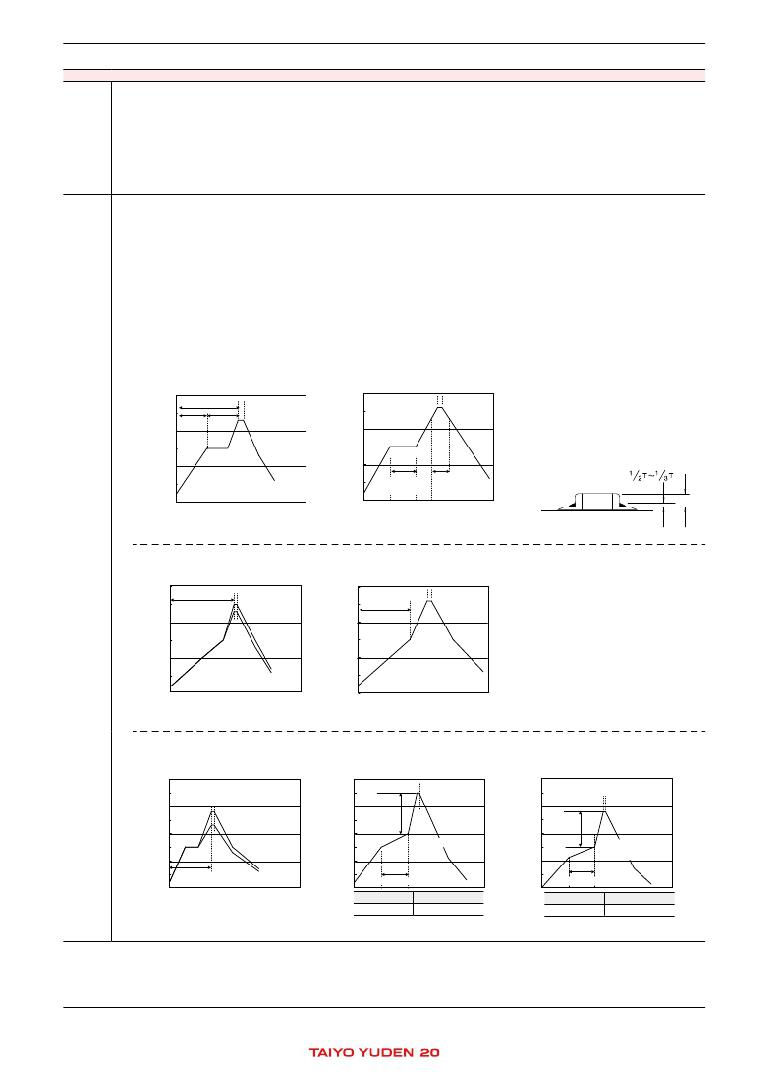

�[� Wave� soldering� ]� 40sec.� Max.� 200�

�Slow� cooling�

�Slow� cooling�

�【� Recommended� conditions� for� eutectic� soldering� 】�

�【� Recommended� condition� for� Pb-free� soldering� 】�

�100�

�100�

�Preheating�

�Technical�

�consider-�

�ations�

�300� 300�

�100�

�300�

�0� 0�

�Preheating� Within� 3sec.�

�120sec.� Min.�

�Preheating�

�40sec.� Max.� 200� 60sec.� Min.�

�Slow� 0�

�cooling�

�300� 300�

�Preheating� 150� ℃� Preheating� Heating� above�

�200� 120sec.� Min.�

�shall� be� kept� as�

�Slow� cooling�

�230� ~� 250� ℃� 100� Peak� 260� ℃� Max.�

�Within� 3sec.� Within� 10sec.�

�Solder�

�Capacitor�

�PC� board�

�T�

�200� 0� 0�

�Slow� cooling�

�Preheating�

�150� ℃�

�300�

�Peak� 260� ℃� Max.�

�Within� 10sec.�

�120sec.� Min.�

�200�

�Slow�

�Preheating� cooling�

�Preheating�

�cooling�

�150� ℃�

�150� ℃�

�①� Wave� soldering� must� not� be� applied� to� capacitors� designated� as� for� re?ow� soldering� only.�

�Peak� 260� ℃� Max.�

�100�

�Within� 3� sec.�

�120sec.� Min.�

�[� Hand� 200� 0� 0�

�Slow�

�【� Recommended� conditions� for� eutectic� soldering� 】�

�【� Recommended� condition� for� Pb-free� soldering� 】�

�Preheating�

�150� ℃�

�400�

�Peak� 350� ℃� Max.�

�Peak� 350� ℃� Max.�

�230� ~� 280� ℃� Within� 3sec.�

�Within� 3� 3� sec.�

�Within� sec.�

�100�

�300�

�300�

�300�

�300�

�0�

�Slow� cooling�

�Slow� cooling�

�0�

�200�

�Preheating� cooling�

�Slow�

�400�

�400�

�150� Peak� 350� ℃� Max.�

�230� ~� 280� ℃�

�Within� 3sec.�

�100�

�Preheating� Min.�

�⊿� T�

�0�

�Slow� cooling�

�⊿� T�

�400�

�300�

�200�

�100�

�0� 0�

�Peak� 280� ℃� Max.�

�Peak� 280� ℃� Max.�

�150� ℃� Peak� 350� ℃� Max.�

�Within� 3sec.�

�⊿� T�

�Slow� cooling�

�Slow� cooling�

�Preheating�

�60sec.� Min.�

�⊿� T�

�120sec.� Min.� 120sec.� Min.�

�200�

�0� Slow�

�cooling�

�300�

�100� Peak� 260� ℃� Max.� 100�

�Within� 10sec.�

�120sec.� Min.�

�200�

�0� Slow� 0�

�cooling�

�Caution� Preheating�

�100�

�230� ~� 280� ℃�

�Within� 10sec.�

�300�

�soldering� ]�

�0�

�cooling� 200�

�400� 400� Slow� cooling�

�100� 230� ~� 280� ℃�

�Within� 3sec.�

�Within� 3� sec.�

�⊿� ⊿� T� T�

�300� Preheating�

�60sec.� Min.�

�200� 200�

�Slow� cooling� Preheating�

�100� 100�

�Within� 3� sec.�

�300� Preheating� 300�

�60sec.� Min.� 60sec.� Min.�

�0� 0� 60sec.� Min.�

�200� 200�

�⊿� T� ≦�

�Slow� cooling� 316type� or� less� Preheating� 150� ℃�

�a� of� 1.0�

�Caution� 150� ℃� Min.�

�①� Use� 100� 50W� soldering� iron� with� a� maximum� tip� diameter� 100� mm.�

�②� The� soldering� iron� shall� not� directly� touch� capacitors.�

�Preheating�

�60sec.� Min.� 60sec.� Min.�

�0� 0�

�400�

�300�

�200�

�400�

�100�

�300�

�0�

�200�

�400�

�100�

�300�

�200�

�100�

�0�

�0�

�Peak� 350� ℃� Max.�

�Within� 3sec.�

�⊿� T�

�Slow� cooling�

�Preheating�

�Within� 3sec.�

�60sec.� Min.�

�⊿� T� Slow� cooling�

�Preheating�

�℃� ℃� Min.� 280�

�150� Peak� Min.� ℃� Max.�

�Within� 3sec.�

�60sec.� Min.�

�Slow� cooling�

�⊿� T�

�⊿� T�

�325type� or� more� Preheating� ≦� 130� ℃�

�150� ℃� Min.�

�60sec.� Min.�

�400�

�300�

�200�

�400�

�100�

�300�

�0�

�200�

�100�

�0�

�⊿� T�

�60sec.� M�

�⊿� T�

�60sec.�

�*� This� catalog� contains� the� typical� speci� ?cation� only� due� to� the� limitation� of� space.� When� you� consider� the� purchase� of� our� products,� please� check� our� speci� ?cation.�

�For� details� of� each� product� (characteristics� graph,� reliability� information,� precautions� for� use,� and� so� on),� see� our� Web� site� (http://www.ty-top.com/)� or� CD� catalogs.�

�mlcc_prec-P3�

�12�

�mlcc_prec_e-01�

�相关PDF资料 |

PDF描述 |

|---|---|

| 3361P-1-202G | TRIMMER 2K OHM 0.5W SMD |

| LD6806F/36P,115 | IC REG LDO 200MA 3.6V 6XSON |

| LD6806F/33P,115 | IC REG LDO 200MA 3.3V 6XSON |

| 3361P-1-102G | TRIMMER 1K OHM 0.5W SMD |

| LD6806F/30P,115 | IC REG LDO 200MA 3.0V 6XSON |

相关代理商/技术参数 |

参数描述 |

|---|---|

| AD7846BPZ | 功能描述:IC DAC 16BIT LC2MOS VOUT 28PLCC RoHS:是 类别:集成电路 (IC) >> 数据采集 - 数模转换器 系列:- 标准包装:1 系列:- 设置时间:4.5µs 位数:12 数据接口:串行,SPI? 转换器数目:1 电压电源:单电源 功率耗散(最大):- 工作温度:-40°C ~ 125°C 安装类型:表面贴装 封装/外壳:8-SOIC(0.154",3.90mm 宽) 供应商设备封装:8-SOICN 包装:剪切带 (CT) 输出数目和类型:1 电压,单极;1 电压,双极 采样率(每秒):* 其它名称:MCP4921T-E/SNCTMCP4921T-E/SNRCTMCP4921T-E/SNRCT-ND |

| AD7846BQ | 制造商:未知厂家 制造商全称:未知厂家 功能描述:16-Bit Digital-to-Analog Converter |

| AD7846JN | 功能描述:IC DAC 16BIT LC2MOS VOUT 28-DIP RoHS:否 类别:集成电路 (IC) >> 数据采集 - 数模转换器 系列:- 产品培训模块:Lead (SnPb) Finish for COTS Obsolescence Mitigation Program 标准包装:1,000 系列:- 设置时间:1µs 位数:8 数据接口:串行 转换器数目:8 电压电源:双 ± 功率耗散(最大):941mW 工作温度:0°C ~ 70°C 安装类型:表面贴装 封装/外壳:24-SOIC(0.295",7.50mm 宽) 供应商设备封装:24-SOIC W 包装:带卷 (TR) 输出数目和类型:8 电压,单极 采样率(每秒):* |

| AD7846JNZ | 功能描述:IC DAC 16BIT LC2MOS VOUT 28-DIP RoHS:是 类别:集成电路 (IC) >> 数据采集 - 数模转换器 系列:- 标准包装:1 系列:- 设置时间:4.5µs 位数:12 数据接口:串行,SPI? 转换器数目:1 电压电源:单电源 功率耗散(最大):- 工作温度:-40°C ~ 125°C 安装类型:表面贴装 封装/外壳:8-SOIC(0.154",3.90mm 宽) 供应商设备封装:8-SOICN 包装:剪切带 (CT) 输出数目和类型:1 电压,单极;1 电压,双极 采样率(每秒):* 其它名称:MCP4921T-E/SNCTMCP4921T-E/SNRCTMCP4921T-E/SNRCT-ND |

| AD7846JNZ | 制造商:Analog Devices 功能描述:IC 12-BIT DAC |

发布紧急采购,3分钟左右您将得到回复。