- 您现在的位置:买卖IC网 > PDF目录19182 > 0638017200 (Molex Inc)CRMP PRESS TM3000 120V TO 10AWG PDF资料下载

参数资料

| 型号: | 0638017200 |

| 厂商: | Molex Inc |

| 文件页数: | 12/24页 |

| 文件大小: | 0K |

| 描述: | CRMP PRESS TM3000 120V TO 10AWG |

| 其它有关文件: | Overlap Style Insulation Crimps |

| 标准包装: | 1 |

| 系列: | TM-3000 |

| 工具类型: | 台式压机,气动 - 无喷枪 |

| 适用于相关产品: | FineAdjust? 和 Mini-Mac? 施用器 |

| 配用: | 638027600-ND - MINI MAC APPLICATOR 14-16 AWG 638027500-ND - MINI MAC APPLICATOR 18-22 AWG 638027200-ND - MINI MAC APPLICATOR 14-18 AWG 638027100-ND - MINI MAC APPLICATOR 14-18 AWG 638027000-ND - MINI MAC APPLICATOR 14-18 AWG 638026900-ND - MINI MAC APPLICATOR 14-18 AWG 0639024800-ND - FINE ADJUST APPLICATOR 0639024700-ND - FINE ADJUST APPLICATOR 0639024600-ND - FINE ADJUST APPLICATOR 0639023900-ND - FINE ADJUST APPLICATOR 更多... |

| 相关产品: | WM5083-ND - GUARD TM-3000&4000 UNIV PRESS WM5082-ND - TERMINAL OILER FOR TM-3000PRESS WM6296-ND - TOOL PRESS SHUT HEIGHT GAUGE |

| 其它名称: | 063801-7200 063801-7200-E 0638017200-E 63801-7200 63801-7200-E 63801-7200-ND 638017200 638017200-E WM4793 |

�� �

�

�

�Quality� Crimp� Handbook�

�SECTION� 7�

�MEASUREMENT�

�Pull� Force� Testing�

�1.� Cut� wire� length� to� approximately� 150mm� (6”)� long.�

�2.� Strip� one� end� to� 13mm� (.50”),� or� long� enough� so� no�

�wire� insulation� is� under� the� insulation� grip,� or�

�loosen� the� insulation� crimp� so� it� has� no� grip� on� the�

�insulation� of� the� wire.�

�3.� Terminate� the� appropriate� terminal� to� the� wire� to�

�the� nominal� crimp� height.�

�4.� Visually� inspect� the� termination� for� bell� mouth,� wire�

�brush� and� cut� strands.�

�5.� Set� pull� tester� to� 254mm� per� minute� (1.00"� per�

�minute).� For� most� applications,� a� higher� rate� will�

�not� have� a� significant� impact� on� the� data.� The�

�slower� rate� prevents� a� sudden� application� of� force�

�or� jerking� that� snaps� strands.� Verify� higher� pull�

�rates� with� data� taken� at� 1.00”� per� minute.�

�6.� If� necessary,� knot� the� un-terminated� end� of� the� wire�

�(If� insulation� slips� on� wire).�

�7.� Regardless� of� pull� tester� type,� both� wire� and�

�terminated� end� must� be� securely� clamped.� (Note:�

�Clamp� terminal� contact� interface,� do� not� clamp�

�conductor� crimp)�

�8.� Activate� pull� test.�

�a.� Record� pull� force� readings.� A� minimum� of� five�

�pull� force� measurements� should� be� done� to�

�confirm� each� set-up.� A� minimum� of� 25� readings�

�should� be� taken� for� determining� process�

�capability.�

�b.� Compare� lowest� reading� to� minimum� pull� force�

�specification.�

�Note:� High� variability� and� lower� value� of� C� pk� (see�

�section� 8� for� explanation� of� C� pk� )� are� common�

�when� two� wires� are� crimped� together.� The�

�variability� is� due� to� more� variation� in� conductor�

�brush,� conductor� bell� mouth� and� fewer� strands� of�

�one� wire� being� in� contact� with� the� serrations� on� the�

�terminal� barrel.� A� double� wire� crimp� is� considered�

�no� better� than� the� smallest� wire� crimped.� Higher�

�pull� force� readings� can� be� seen� if� both� wires� are�

�gripped� and� pulled� exactly� together.� Pulling� each�

�wire� individually� will� result� in� a� much� lower� pull�

�force� reading.� If� both� wires� are� of� the� same� size,�

�the� top� wire� will� normally� result� in� a� lower� reading� than�

�the� bottom� wire� due� to� the� effects� of� the� terminal�

�serrations.�

�Wire� Chart�

�Note:� Pull� force� has� only� a� minimum� specification.� For� C� pk�

�calculations,� the� average� reading� is� assumed� nominal� and�

�the� upper� specification� limit� is� set� so� C� p� and� C� pk� are� equal.�

�High� pull� force� readings� that� increase� the� standard�

�deviation� can� lower� C� pk� even� if� the� mean� and� lowest�

�reading� are� increased.�

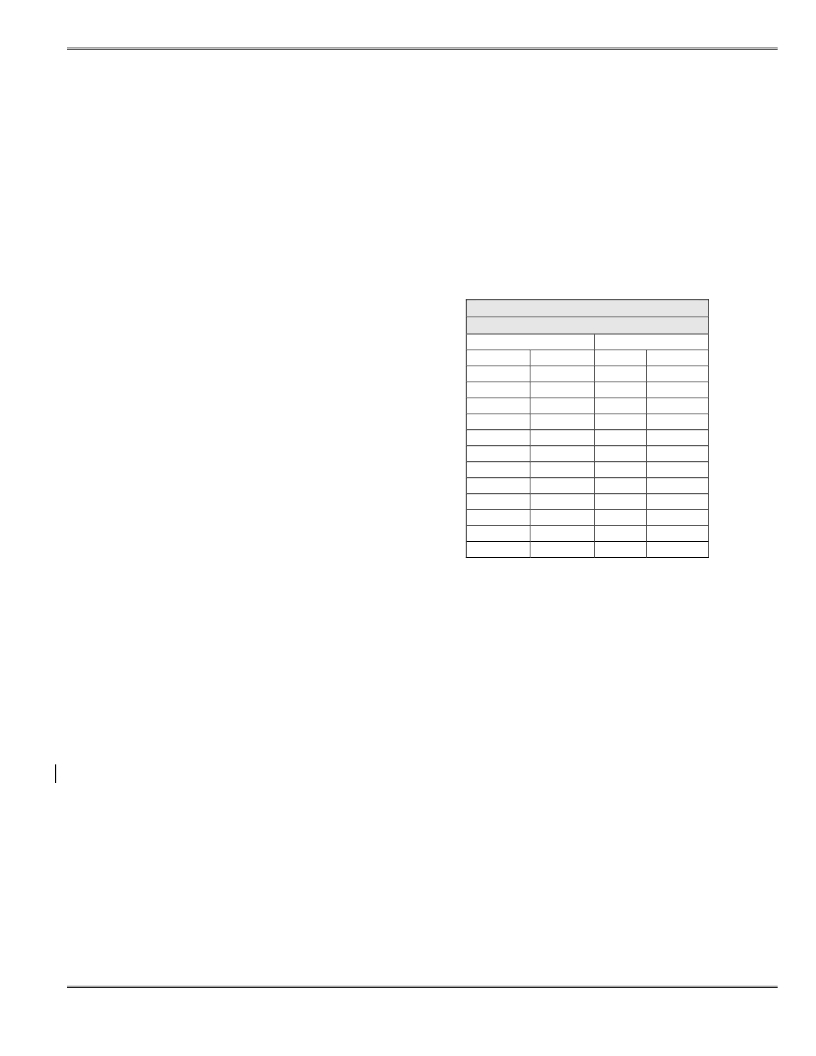

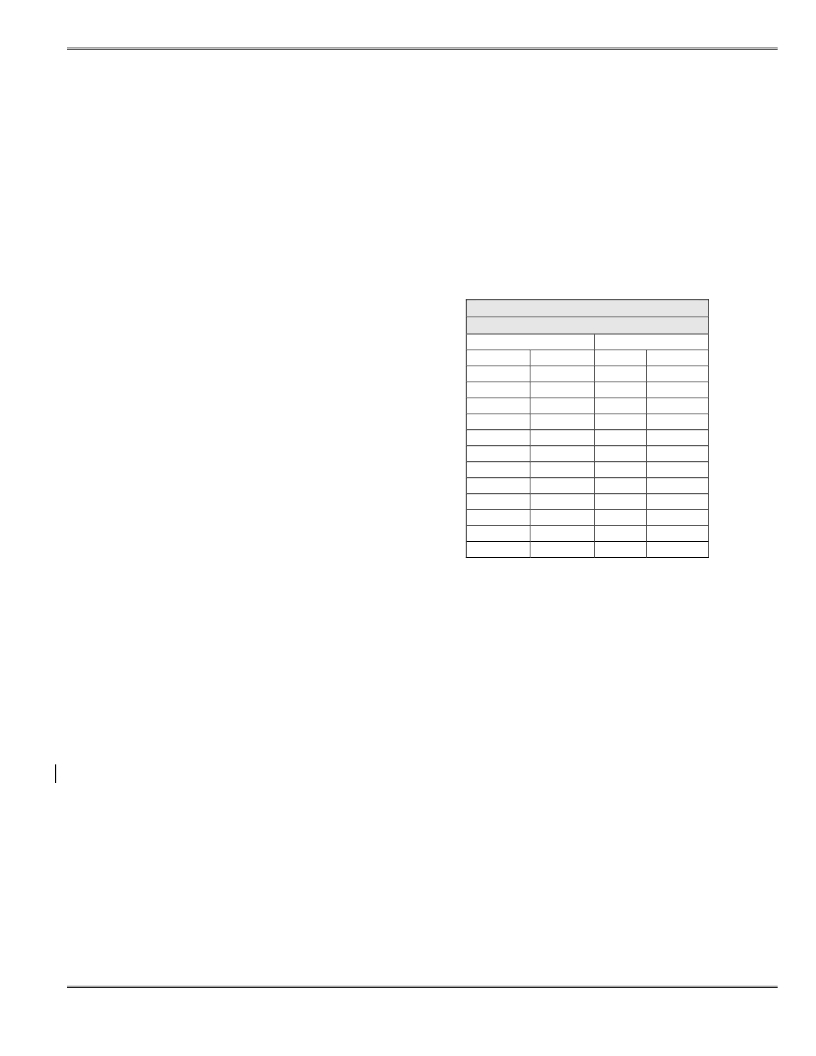

�Test� Values� for� Pull� Force� Test�

�UL486A�

�Size� of� Conductor� Pullout� Force*�

�AWG� mm� 2� Lbf� N�

�30� 0.05� 1.5� 6.7�

�28� 0.08� 2� 8.9�

�26� 0.13� 3� 13.4�

�24� 0.20� 5� 22.3�

�22� 0.324� 8� 35.6�

�20� 0.519� 13� 57.9�

�18� 0.823� 20� 89.0�

�16� 1.31� 30� 133.5�

�14� 2.08� 50� 222.6�

�12� 3.31� 70� 311.5�

�10� 5.261� 80� 356.0�

�8� 8.367� 90� 400.5�

�*Consult� individual� specifications�

�Crimp� Height� Testing�

�1.� Complete� tool� set-up� procedure.�

�2.� Crimp� a� minimum� of� five� samples.�

�3.� Place� the� flat� blade� of� the� crimp� micrometer� across� the�

�center� of� the� dual� radii� of� the� conductor� crimp.� Do� not�

�take� the� measurement� near� the� conductor� bell� mouth.�

�4.� Rotate� the� micrometer� dial� until� the� point� contacts� the�

�bottom� radial� surface.� If� using� a� caliper,� be� certain� not�

�to� measure� the� extrusion� points� of� the� crimp.�

�5.� Record� crimp� height� readings.� A� minimum� of� five� crimp�

�height� readings� is� necessary� to� confirm� each� set-up.� A�

�minimum� of� 25� readings� is� necessary� to� determine�

�capability.�

�6.� Check� crimp� height� every� 250� to� 500� parts� throughout�

�the� run.�

�Order� No:� TM-638000029�

�Revision:� D�

�Release� Date:� 09-04-03�

�Revision� Date:� 12-23-09�

�UNCONTROLLED� COPY�

�Page� 12� of� 24�

�相关PDF资料 |

PDF描述 |

|---|---|

| NDKR16H | SW ROTARY DIP 8MM HEX RT ANG PC |

| MMA2260EGR2 | SENSOR ACCEL X-AXIS 1.5G 16-SOIC |

| 63811-8000 | TOOL HAND CRIMP 22-28AWG |

| 555-4003F | LED 2MM QUAD 5V RED |

| 555-4401F | LED 2MM QUAD YELLOW |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 0638017205 | 功能描述:FACE PLATE 制造商:molex, llc 系列:* 零件状态:在售 标准包装:1 |

| 0638017206 | 功能描述:SWITCH TDC 制造商:molex, llc 系列:* 零件状态:过期 标准包装:1 |

| 0638017207 | 功能描述:SWITCH W CABLE TDC 制造商:molex, llc 系列:* 零件状态:在售 标准包装:1 |

| 0638017208 | 功能描述:ACCESS COVER 制造商:molex, llc 系列:* 零件状态:在售 标准包装:1 |

| 0638017211 | 制造商:Molex 功能描述:PROX SPLIT CYCLE 制造商:Molex 功能描述:PROX SPLIT CYCLE - Bulk 制造商:Molex 功能描述:PROX SPLIT CYCLE |

发布紧急采购,3分钟左右您将得到回复。