- 您现在的位置:买卖IC网 > PDF目录19180 > 0639004500 (Molex Inc)FINE ADJUST APPLICATOR PDF资料下载

参数资料

| 型号: | 0639004500 |

| 厂商: | Molex Inc |

| 文件页数: | 16/24页 |

| 文件大小: | 0K |

| 描述: | FINE ADJUST APPLICATOR |

| RoHS指令信息: | 0639004500 Cert of Compliance |

| 标准包装: | 1 |

| 系列: | FineAdjust™, Micro-Fit 3.0™ |

| 工具类型: | 台式压机,施用器 |

| 适用于相关产品: | 矩形触点,20-24 AWG |

| 配用: | WM2777CT-ND - CONN TERM MALE 20-24AWG GOLD WM2776CT-ND - CONN TERM FEMALE 20-24AWG 30GOLD WM2777TR-ND - CONN TERM MALE 20-24AWG GOLD WM2776TR-ND - CONN TERM FEMALE 20-24AWG 30GOLD WM1127CT-ND - CONN TERM MALE 20-24AWG GOLD WM1841CT-ND - CONN TERM MALE 20-24AWG TIN WM1125CT-ND - CONN TERM FEMALE 20-24AWG GOLD WM1837CT-ND - CONN TERM FEMALE 20-24AWG TIN WM1127TR-ND - CONN TERM MALE 20-24AWG GOLD WM1841TR-ND - CONN TERM MALE 20-24AWG TIN 更多... |

| 相关产品: | WM3459-ND - TM3000 220V/50HZ PRESS TO 10AWG WM6378-ND - PRESS TM4000 UP TO 4AWG 240AC WM4793-ND - CRMP PRESS TM3000 120V TO 10AWG |

| 其它名称: | 063900-4500 63900-4500 639004500 WM3461 |

�� �

�

�

�Quality� Crimp� Handbook�

�Two� operators� may� measure� the� same� part� differently,�

�or� the� same� operator� may� measure� the� part� differently�

�when� using� two� types� of� gauges.� Molex� recommends� a�

�gauge� capability� study� to� identify� what� part� of� the�

�variability� is� coming� from� measurement� error.� Micro-�

�terminals� crimped� to� small� wire� sizes� need� a� tight� crimp�

�height� range� to� maintain� pull� force.� The� variability� from�

�measurement� error� can� keep� C� pk� values� low.�

�The� capability� of� the� crimping� tools� needs� to� be� re-�

�confirmed� if� the� production� data� is� significantly� different�

�changes,� or� setup� adjustments.� Record� the� data� point�

�on� the� chart� before� making� a� crimp� height� adjustment.�

�If� data� is� recorded� after� each� adjustment,� the� process� is�

�likely� to� assume� control� and� provide� little� data� for�

�improving� the� process.� The� operator� needs� to� make� as�

�many� notes� as� possible� on� the� chart.� The� only� truly�

�effective� and� economically� sensible� way� to� manage� a�

�manufacturing� process� is� to� understand,� monitor� and�

�reduce� sources� of� variability� that� are� inherent� to� the�

�process� itself.� Every� minute� required� for� setup� or�

�adjustments� is� unproductive.�

�from� the� capability� study.�

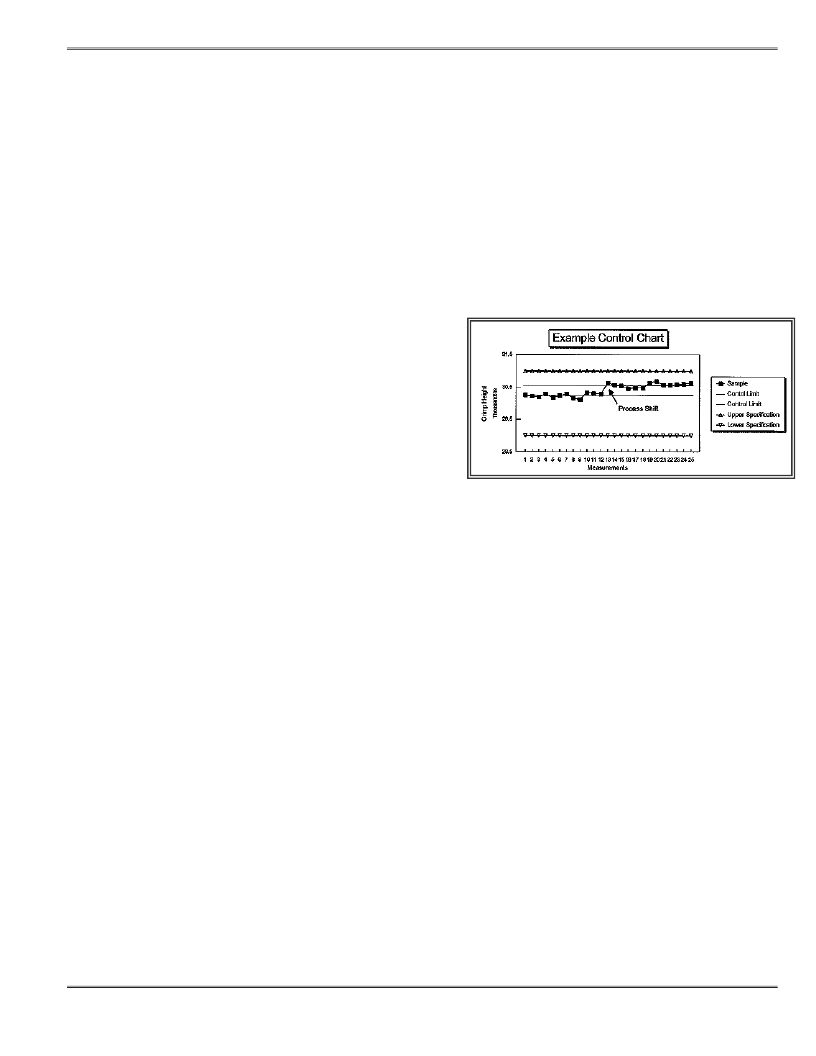

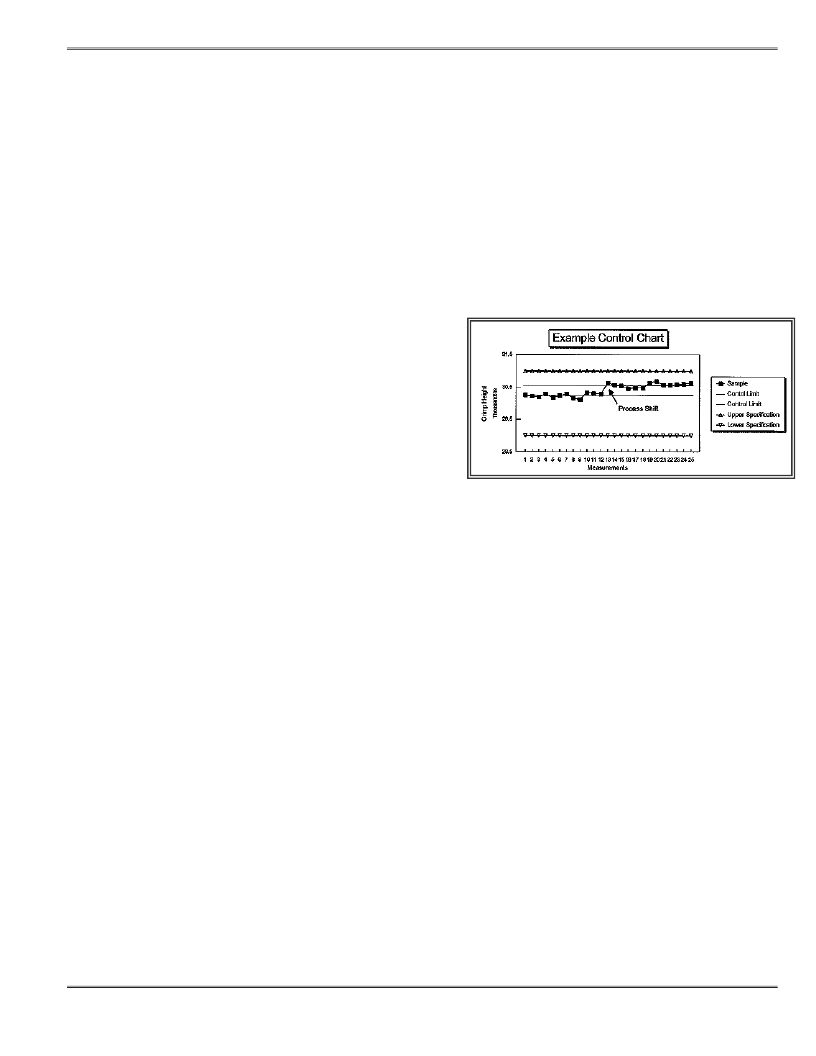

�What� does� this� sample� chart� tell� us?�

�Production�

�Before� the� tool� is� ready� for� production,� the� level� of�

�capability� needs� to� be� established.� Many� harness�

�manufacturers� run� only� a� few� hundred� or� few� thousand�

�wires� at� one� time.� In� this� case,� it� is� not� practical� or�

�economical� to� run� a� twenty-five-piece� capability� with�

�every� set-up.�

�Visual� Inspection�

�X� and� R� Chart�

�It� needs� to� be� standard� operating� procedure� for� the�

�operator� to� manually� fan� each� bundle� of� crimped� wires�

�and� visually� check� bell� mouth,� conductor� brush,�

�insulation� position,� cut-off� tab� length,� and� insulation�

�crimp.�

�Control� Charting�

�Crimp� height� is� typically� control� charted� because� it� is� a�

�quick� nondestructive� measurement� and� is� critical� for� the�

�termination's� electrical� and� mechanical� reliability.�

�There� are� three� primary� purposes� for� control� charting.�

�One,� the� number� of� setup� samples� is� usually� small,� with�

�limited� statistical� value.� Two,� since� special� cause�

�effects� on� a� process� are� irregular� and� unpredictable;� it�

�is� necessary� to� be� able� to� catch� changes� in� the� process�

�as� soon� as� they� occur.� This� prevents� thousands� of�

�terminations� from� being� scrapped� after� the� run� is� over.�

�Three,� and� most� important,� this� data� is� necessary� to�

�assess� and� improve� the� crimp� process.�

�Control� limit� for� sample� of� 5� =� Avg�

�(Avg� of� 5� readings)� +� .577� x� Avg� (Ranges)�

�It� indicates� that� a� process� shift� occurred� between�

�measurement� 12� and� 13.� This� type� of� shift� could� occur�

�due� to� a� change� in� wire,� a� change� in� terminal� lots,� a�

�jam� in� the� machine� that� damaged� the� tooling,� a� change�

�in� operators,� or� an� adjustment� to� the� insulation� crimp.�

�Since� the� measurements� are� still� within� specification,�

�would� you� stop� production� to� adjust� crimp� height?�

�A� shift� in� the� process� due� to� a� change� in� material� may�

�warrant� a� crimp� height� adjustment.� A� shift� after� a� jam�

�would� not� indicate� an� adjustment,� but� a� close�

�evaluation� of� the� tooling.� A� shift� in� the� process�

�between� operators� would� not� indicate� an� adjustment,�

�but� an� evaluation� of� measurement� capability.� The�

�purpose� of� a� control� chart� is� to� identify� what� caused� the�

�shift� in� process� to� determine� if� an� adjustment� to� the�

�process� is� needed.�

�Once� the� tooling� process� is� setup� and� the� wire� size�

�does� not� change,� keep� one� control� chart� for� wire� color�

�changes,� wire� length� changes,� terminal� material�

�Order� No:� TM-638000029�

�Revision:� D�

�Release� Date:� 09-04-03�

�Revision� Date:� 12-23-09�

�UNCONTROLLED� COPY�

�Page� 16� of� 24�

�相关PDF资料 |

PDF描述 |

|---|---|

| A6H-8102-P | DIP SWITCH |

| MMA7361LT | ACCELEROMETER 1.5G XYZ 14-LGA |

| MMA7361LR2 | ACCELEROMETER 1.5G XYZ 14-LGA |

| A6A-10RF | SWITCH ROTARY DIP BCD FLAT |

| MMA7361LR1 | ACCELEROMETER 1.5G XYZ 14-LGA |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 0639004570 | 功能描述:TOOL KIT RoHS:是 类别:工具 >> 压接器,施用器,压力机 - 配件 系列:* 标准包装:1 系列:- 其它名称:512A512A-NDQ1137690B |

| 0639004600 | 功能描述:FINE ADJUST APPLICATOR RoHS:是 类别:工具 >> 压接器,施用器,压力机 系列:FineAdjust™, SPOX™ 产品培训模块:Board-to-Wire Connectors 标准包装:1 系列:DF11 工具类型:台式压机,施用器 适用于相关产品:矩形触点,24-28 AWG 特点:- 配用:H1505TR-ND - CONN SOCKET 24-28AWG CRIMP GOLDH1504TR-ND - CONN SOCKET 24-28AWG CRIMP TIN 相关产品:AP105-DF11-2428S(64)-ND - TOOL APPLICATOR DF11 ACCESSORIESAP105-DF11-2428S(63)-ND - TOOL APPLICATOR DF11 ACCESSORIESAP105-DF11-2428S(62)-ND - TOOL APPLICATOR DF11 ACCESSORIESAP105-DF11-2428S(61)-ND - TOOL APPLICATOR DF11 ACCESSORIESCM-105 WITH TRANSFORMER-ND - TOOL AUTO CRIMPING MACHINE 其它名称:*AP105-DF11-2428SQ1139807AQ949366 |

| 0639004670 | 功能描述:TOOL KIT RoHS:是 类别:工具 >> 压接器,施用器,压力机 - 配件 系列:* 标准包装:1 系列:- 其它名称:512A512A-NDQ1137690B |

| 0639004700 | 制造商:Molex 功能描述:FINE-ADJUST APPLICATOR FOR MICRO SPOX CRIMP TERMINAL, 22-30 AWG 制造商:Molex 功能描述:FINEADJUST APPLICATOR FOR MICRO SPOX CRMP TERM, 22-30 AWG - Bulk |

| 0639004770 | 功能描述:TOOL KIT RoHS:是 类别:工具 >> 压接器,施用器,压力机 - 配件 系列:* 标准包装:1 系列:- 其它名称:512A512A-NDQ1137690B |

发布紧急采购,3分钟左右您将得到回复。