- 您现在的位置:买卖IC网 > PDF目录20398 > 16N78-212E.1001 (Portescap)MOTOR BRUSHED DC 4W 12V 8400RPM PDF资料下载

参数资料

| 型号: | 16N78-212E.1001 |

| 厂商: | Portescap |

| 文件页数: | 5/48页 |

| 文件大小: | 0K |

| 描述: | MOTOR BRUSHED DC 4W 12V 8400RPM |

| 标准包装: | 10 |

| 系列: | 16N78, Athlonix |

| 类型: | 有刷直流 |

| 电压 - 额定: | 12VDC |

| RPM: | 8400 RPM |

| 直径 - 主体: | 0.630"(16.00mm) |

| 直径 - 轴: | 0.059"(1.50mm) |

| 长度 - 轴和支架: | 0.295"(7.50mm) |

| 安装孔间距: | 0.394"(10.00mm) |

| 端接类型: | 焊片 |

| 转矩 - 停滞状态 (oz-in / mNm): | 1.76 / 12.4 |

| 齿轮减速比: | 无 |

| 功率(瓦特): | 4W |

| 重量: | 0.053 磅(24.04g) |

| 其它名称: | 403-1042 |

第1页第2页第3页第4页当前第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页第37页第38页第39页第40页第41页第42页第43页第44页第45页第46页第47页第48页

�� �

�

�

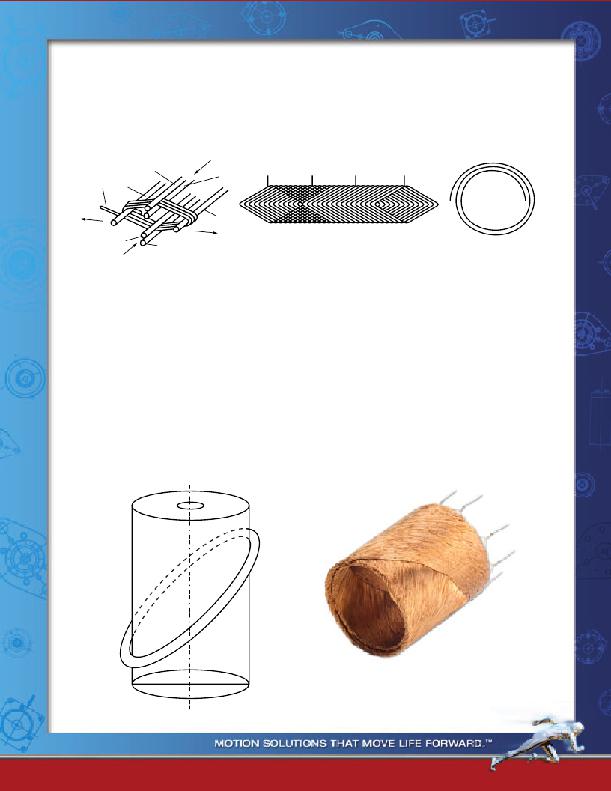

�B� —� A� method� which� avoids� these� coil� heads� uses� an� armature� wire� that� is� covered� with� an� outer� layer� of� plastic� for�

�adhesion,� and� is� wound� on� a� mobile� lozenge-shaped� support.� Later,� the� support� is� removed,� and� a� flat� armature� package�

�is� obtained,� which� is� then� formed� into� a� cylindrical� shape� (Figure� 1).� The� difficulty� with� this� method� lies� in� achieving� a�

�completely� uniform� cylinder.� This� is� necessary� for� minimum� ripple� of� the� created� torque,� and� for� a� minimum� imbalance� of�

�the� rotor.�

�Figure� 1� -� Continuous� winding� on� mobile� support�

�2a�

�3�

�1�

�1a�

�2�

�5�

�a)� support� arrangement�

�b)� armature� as� flat� package�

�c)� forming� of� armature�

�in� cylindrical� shape�

�C� —� A� procedure� which� avoids� having� to� form� a� perfect� cylinder� from� a� flat� package� consists� of� winding� the� wire� directly�

�and� continuously� onto� a� cylindrical� support.� This� support� then� remains� inside� the� rotor.� Coil� heads� are� reduced� to� a�

�minimum.�

�Although� a� large� air� gap� is� necessary� to� accommodate� the� armature� support;� this� method� is,� however,� easily� automated.�

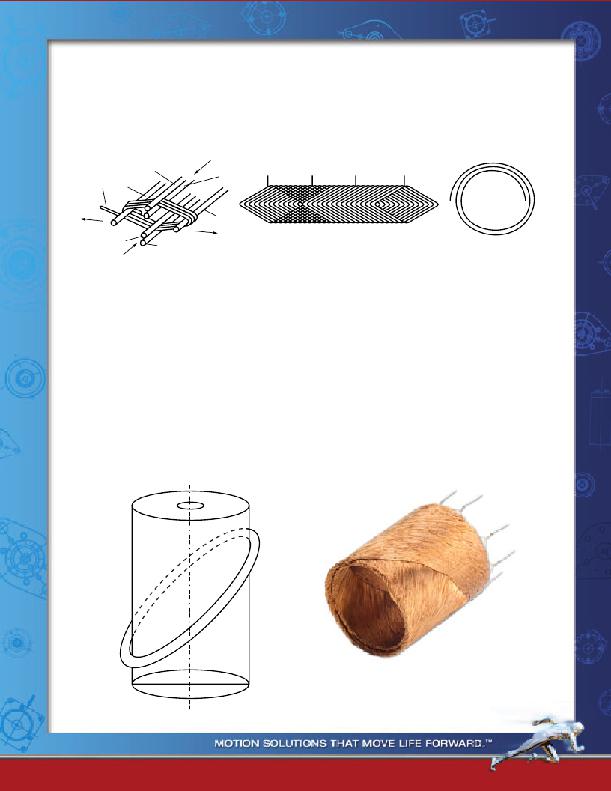

�D� —� The� Skew-Wound� armature� method� utilizes� the� same� two-layer� plastic� coated� wire� described� in� Method� B.� This� Wire�

�is� directly� and� continuously� wound� onto� a� cylindrical� support� which� is� later� removed,� thus� eliminating� an� excessive� air� gap�

�and� minimizing� rotor� inertia.� In� this� type� of� winding,� inactive� coil� heads� are� non-existent.� (Figure� 2).� This� kind� of� armature�

�winding� does� require� relatively� complex� coil� winding� machines.� Portescap� thru� its� proprietary� know� how� has� developed�

�multiple� automated� winding� machines� for� different� frame� sizes� and� continues� to� innovate� in� the� space� so� that� dense� coil�

�windings� can� be� spun� in� these� automated� machines.�

�Figure� 2�

�相关PDF资料 |

PDF描述 |

|---|---|

| T95Z685M035LSAL | CAP TANT 6.8UF 35V 20% 2910 |

| 16N78-212P.1001 | MOTOR BRUSHED DC 4W 6V 9300RPM |

| MSS1P6-E3/89A | DIODE SCHOTTKY 1A 60V MICROSMP |

| 12G88-215E.1001 | MOTOR BRUSHED DC 2.5W 4.5V |

| FAN7361M | IC DRIVER GATE HIGH SIDE 8SOIC |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 16N78-212P.1001 | 功能描述:MOTOR BRUSHED DC 4W 6V 9300RPM RoHS:是 类别:电机,螺线管 >> 电机 - AC,DC 系列:16N78, Athlonix 标准包装:1 系列:OMNUC G 类型:伺服 AC 电压 - 额定:200VAC RPM:1000 RPM 直径 - 主体:6.93"(176.00mm) 直径 - 轴:1.38"(35.00mm) 长度 - 轴和支架:3.15"(80.00mm) 安装孔间距:7.87"(200.00mm) 特点:绝对式编码器,键 端接类型:连接器 转矩 - 运行(oz-in / mNm):4021.8 / 28400 转矩 - 启动状态 (oz-in / mNm):- 转矩 - 停滞状态 (oz-in / mNm):- 齿轮减速比:无 电压范围:- 功率(瓦特):3kW 重量:55 磅(24.9kg) 其它名称:R88MG3K010TS2 |

| 16N78214E1001 | 功能描述:有刷 DC 标准 电机 10000 RPM 5.2W 9VDC 制造商:portescap 系列:16N78 Athlonix 零件状态:有效 类型:直流电机 功能:标准 电机类型:有刷 电压 - 额定:9VDC RPM:10000 RPM 扭矩 - 额定值 (oz-in / mNm):0.94 / 6.6 功率 - 额定值:5.2W 编码器类型:- 大小/尺寸:圆形 - 0.629" 直径(16.00mm) 直径 - 轴:0.059"(1.50mm) 长度 - 轴和轴承:0.295"(7.50mm) 安装孔间距:0.394"(10.00mm) 端子类型:焊片 特性:- 齿轮减速比:- 扭矩 - 瞬时最大值?(oz-in / mNm):- 工作温度:-30°C ~ 85°C 认可:- 重量:0.053 磅(24.04g) 标准包装:10 |

| 16N849 | 制造商:Distributed By MCM 功能描述:8" PLENUM RATED WIRE TIESRED 100/PKG |

| 16NA1000MEFC12.5X20 | 功能描述:CAP ALUM 1000UF 16V 20% BI-P RAD RoHS:是 类别:电容器 >> 铝 系列:* 标准包装:2,000 系列:142 RHS 电容:4700µF 额定电压:10V 容差:±20% 寿命@温度:105°C 时为 2000 小时 工作温度:-40°C ~ 105°C 特点:通用 纹波电流:1.26A ESR(等效串联电阻):- 阻抗:- 安装类型:通孔 封装/外壳:径向,Can 尺寸/尺寸:0.492" 直径(12.50mm) 高度 - 座高(最大):1.063"(27.00mm) 引线间隔:0.197"(5.00mm) 表面贴装占地面积:- 包装:散装 |

| 16NA100MEFC6.3X11 | 功能描述:CAP ALUM 100UF 16V 20% BI-P RAD RoHS:是 类别:电容器 >> 铝 系列:* 标准包装:2,000 系列:142 RHS 电容:4700µF 额定电压:10V 容差:±20% 寿命@温度:105°C 时为 2000 小时 工作温度:-40°C ~ 105°C 特点:通用 纹波电流:1.26A ESR(等效串联电阻):- 阻抗:- 安装类型:通孔 封装/外壳:径向,Can 尺寸/尺寸:0.492" 直径(12.50mm) 高度 - 座高(最大):1.063"(27.00mm) 引线间隔:0.197"(5.00mm) 表面贴装占地面积:- 包装:散装 |

发布紧急采购,3分钟左右您将得到回复。