- 您现在的位置:买卖IC网 > PDF目录19056 > 1725616-1 (TE Connectivity)KIT SEATING TOOL 2X1 LO PROFILE PDF资料下载

参数资料

| 型号: | 1725616-1 |

| 厂商: | TE Connectivity |

| 文件页数: | 3/5页 |

| 文件大小: | 0K |

| 描述: | KIT SEATING TOOL 2X1 LO PROFILE |

| 标准包装: | 1 |

| 系列: | * |

�� �

�

�

�408-� 8848�

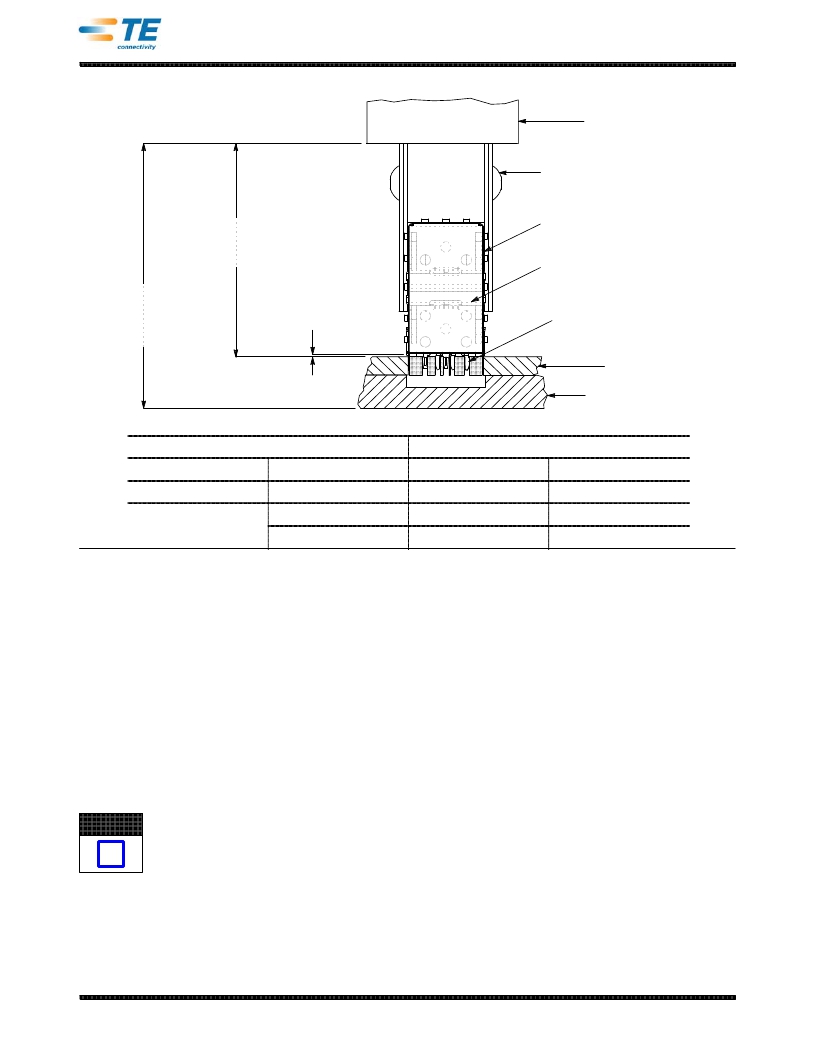

�Note:� Not� to� Scale�

�Tool� Seating� Height�

�(See� Table)�

�(With� Product� Seated)�

�Ram� of� Application� Tool�

�(Fully� Down)�

�Seating� Tool� (1490197--� 2� Shown)�

�Cage� Assembly�

�Wall� Support� (Installed� in�

�Ports� of� Cage� Assembly)�

�Application� Tool�

�Shut� Height�

�(Ram� Fully� Down)�

�(See� Section� 4,� Step� 1)�

�0.10� mm� [.004� in.]�

�(Max)� Gap� Allowed�

�SFP� PRODUCT�

�Compliant� Pin� Contacts� (and� Any�

�Protruding� Components)� Inserted�

�into� Holes� in� PC� Board� and�

�PC� Board� Support� Fixture�

�PC� Board�

�PC� Board� Support� Fixture�

�SEATING� HEIGHT� (mm� [in.])�

�CONFIGURATION�

�1� ¢� 2,� 1� ¢� 4,� 1� ¢� 6�

�2� ¢� 1,� 2� ¢� 4,� 2� ¢� 6�

�PROFILE�

�—�

�Standard�

�Low�

�TOOL�

�38.61� [1.52]�

�40.64� [1.60]�

�37.59� [1.48]�

�PRODUCT�

�9.7� [.382]�

�25.5� [1.004]�

�22.55� [.888]�

�Figure� 2�

�i�

�6.� Check� the� product� for� proper� seating� according�

�to� the� following:�

�a.� the� widest� section� of� each� compliant� pin� is�

�inside� its� intended� pc� board� hole�

�b.� each� alignment� post� is� in� its� intended� pc�

�board� hole�

�c.� the� product� is� seated� on� the� pc� board� with� a�

�seating� height—measured� from� the� top� of� the�

�product� (not� including� the� panel� ground� springs)�

�to� the� top� of� the� pc� board—given� in� Figure� 2�

�d.� if� present,� the� gap� between� the� standoffs� and�

�the� pc� board� is� no� more� than� 0.10� mm� [.004� in.]�

�NOTE� For� detailed� application� requirements� of� the�

�product,� refer� to� the� relative� application�

�specification� listed� in� Figure� 1.�

�6.� MAINTENANCE� AND� INSPECTION�

�The� seating� tool� is� assembled� and� inspected� before�

�shipment.� It� is� recommended� that� the� seating� tool� be�

�inspected� immediately� upon� arrival� at� your� facility� to�

�Rev� E�

�ensure� that� it� has� not� been� damaged� during�

�shipment,� and� that� it� conforms� to� the� dimensions�

�provided� in� Figure� NO� TAG.�

�6.1.� Daily� Maintenance�

�It� is� recommended� that� each� operator� be� made� aware�

�of,� and� responsible� for,� the� following� steps� of� daily�

�maintenance.�

�1.� Remove� dust,� moisture,� and� contaminants� with�

�a� clean,� soft� brush� or� a� lint--free� cloth.� DO� NOT�

�use� objects� that� could� damage� the� components.�

�2.� When� the� seating� tool� and� wall� support� are� not�

�in� use,� store� them� in� a� clean,� dry� area.�

�6.2.� Periodic� Inspection�

�Regular� inspections� should� be� performed� by� quality�

�control� personnel.� A� record� of� scheduled� inspections�

�should� remain� with� the� seating� tool� or� be� supplied� to�

�personnel� responsible� for� the� seating� tool� kit.�

�Inspection� frequency� should� be� based� on� amount� of�

�use,� working� conditions,� operator� training� and� skill,�

�and� established� standards.�

�3� of� 5�

�相关PDF资料 |

PDF描述 |

|---|---|

| 803482 | BOARD LED IMS SEOUL SEMI P7 |

| 803290 | BOARD LED IMS NICHIA PWRLED |

| ASVTX-12-A-19.200MHZ-I15-T | TCVCXO 19.200 MHZ 3.0V SMD |

| 803119 | BOARD LED IMS SEOUL SEMI Z-PWR |

| 91348-2 | SEATING TL HDR 2 PR 20 COL |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 1725618-1 | 制造商:TE Connectivity 功能描述:SEATING TL,2X4 KIT,L.P. - Bulk |

| 1725620000 | 功能描述:CONN HDR 5.08MM 44POS 90 BLK RoHS:是 类别:连接器,互连式 >> 接线座 - 接头,插头和插口 系列:Omnimate SLD 标准包装:50 系列:COMBICON PC 端接块类型:插头,母插口 每电平位置:8 间距:0.300"(7.62mm) 级别数目:1 接头定向:- 插头导线入口:180° 端子:螺钉 线规:8-24 AWG 电流:41A 电压:600V 安装类型:自由悬挂 特点:法兰 颜色:绿 包装:散装 其它名称:PC 5/ 8-STF-7,62PC5/8-STF-7,62 |

| 1725623 | 功能描述:可插拔接线端子 PTDA 2.5/ 7-PH-5.0 7P 5.0MM PLUGGABLE RoHS:否 制造商:Phoenix Contact 产品:Plugs 系列:PTS 端接类型:Spring Cage 位置/触点数量:5 线规量程:26-14 节距:5 mm 电流额定值:10 A 电压额定值:250 V 安装风格: 安装角: 触点电镀: |

| 1725623-1 | 功能描述:手工工具 SEATING TOOL RoHS:否 制造商:Molex 产品:Extraction Tools 类型: 描述/功能:Extraction tool |

| 1725624-1 | 功能描述:手工工具 SEATING TOOL RoHS:否 制造商:Molex 产品:Extraction Tools 类型: 描述/功能:Extraction tool |

发布紧急采购,3分钟左右您将得到回复。