参数资料

| 型号: | 3M 4930 1" X 2"-100 |

| 厂商: | 3M (TC) |

| 文件页数: | 9/11页 |

| 文件大小: | 0K |

| 描述: | 3M 4930 VHB 1" X 2" - 100/PACK |

| 视频文件: | 3M VHB adhesive demonstration - Another Geek Moment |

| MSDS 材料安全数据表: | 49zz MSDS |

| 标准包装: | 1 |

| 系列: | VHB™ 4930 |

| 胶带类型: | 双涂层,双面 |

| 胶合剂: | 丙烯酸 |

| 背衬,载体: | 纸 |

| 厚度: | 0.025"(25 mils,0.635mm) |

| 宽: | 1.00"(25.40mm) |

| 长度: | 2.00"(50.80mm) |

| 颜色: | 白 |

| 使用: | 通用 |

| 温度范围: | 200°F(93°C) |

| 包装: | 散装 |

| 其它名称: | 3M11111 |

�� �

�

�

�3M� ?� VHB� ?� Tapes�

�Application� Techniques�

�Clean:� Most� substrates� are� best� prepared� by� cleaning� with� a� 50:50� mixture� of� isopropyl� alcohol� (IPA*)� and�

�water� prior� to� applying� 3M?� VHB?� Tapes.�

�Exceptions� to� the� general� procedure� that� may� require� additional� surface� preparation� include:�

�?� Heavy� Oils:� A� degreaser� or� solvent-based� cleaner� may� be� required� to� remove� heavy� oil� or� grease� from� a�

�surface� and� should� be� followed� by� cleaning� with� IPA/water.�

�?� Abrasion:� Abrading� a� surface,� followed� by� cleaning� with� IPA/water,� can� remove� heavy� dirt� or� oxidation�

�and� can� increase� surface� area� to� improve� adhesion.�

�?� Adhesion� Promoters:� Priming� a� surface� can� significantly� improve� initial� and� ultimate� adhesion� to� many�

�materials� such� as� plastics� and� paints.�

�?� Porous� surfaces:� Most� porous� and� fibered� materials� such� as� wood,� particleboard,� concrete,� etc.� need� to� be�

�sealed� to� provide� a� unified� surface.�

�?� Unique� Materials:� Special� surface� preparation� may� be� needed� for� glass� and� glass-like� materials,� copper�

�and� copper� containing� metals,� and� plastics� or� rubber� that� contain� components� that� migrate� (e.g.� plasticizers).�

�Refer� to� 3M� Technical� Bulletin� “Surface� Preparation� for� 3M?� VHB?� Tape� Applications”� for� additional�

�details� and� suggestions.� (70-0704-8701-5)�

�*Note:� These� cleaner� solutions� contain� greater� than� 250� g/l� of� volatile� organic� compounds� (VOC).� Please�

�consult� your� local� Air� Quality� Regulations� to� be� sure� the� cleaner� is� compliant.� When� using� solvents,�

�be� sure� to� follow� the� manufacturer� ’s� precautions� and� directions� for� use� when� handling� such� materials.�

�Pressure:� Bond� strength� is� dependent� upon� the� amount� of� adhesive-to-surface� contact� developed.� Firm�

�application� pressure� develops� better� adhesive� contact� and� helps� improve� bond� strength.� Typically,� good� surface�

�contact� can� be� attained� by� applying� enough� pressure� to� insure� that� the� tape� experiences� approximately� 15� psi�

�(100� kPa)� pressure.� Either� roller� or� platen� pressure� can� be� used.� Note� that� rigid� surfaces� may� require� 2� or� 3� times�

�that� much� pressure� to� make� the� tape� experience� 15� psi.�

�Temperature:� Ideal� application� temperature� range� is� 70°F� to� 100°F� (21°C� to� 38°C).� Pressure� sensitive�

�adhesives� use� viscous� flow� to� achieve� substrate� contact� area.� Minimum� suggested� application� temperatures:�

�?� 50°F� (10°C):� 3M?� VHB?� Tapes� 4950,� 5952,� 4910,� 4952,� 4611,� 4622� families.�

�?� 60°F� (15°C):� 3M?� VHB?� Tapes� 4941,� 4945� families.�

�?� 32°F� (0°C):� 3M?� VHB?� Tape� 4951� families.�

�Note:� Initial� tape� application� to� surfaces� at� temperatures� below� these� suggested� minimums� is� not�

�recommended� because� the� adhesive� becomes� too� firm� to� adhere� readily.� However,� once� properly�

�applied,� low� temperature� holding� is� generally� satisfactory.�

�To� obtain� good� performance� with� all� 3M?� VHB?� Tapes,� it� is� important� to� ensure� that� the� surfaces� are� dry�

�and� free� of� condensed� moisture.�

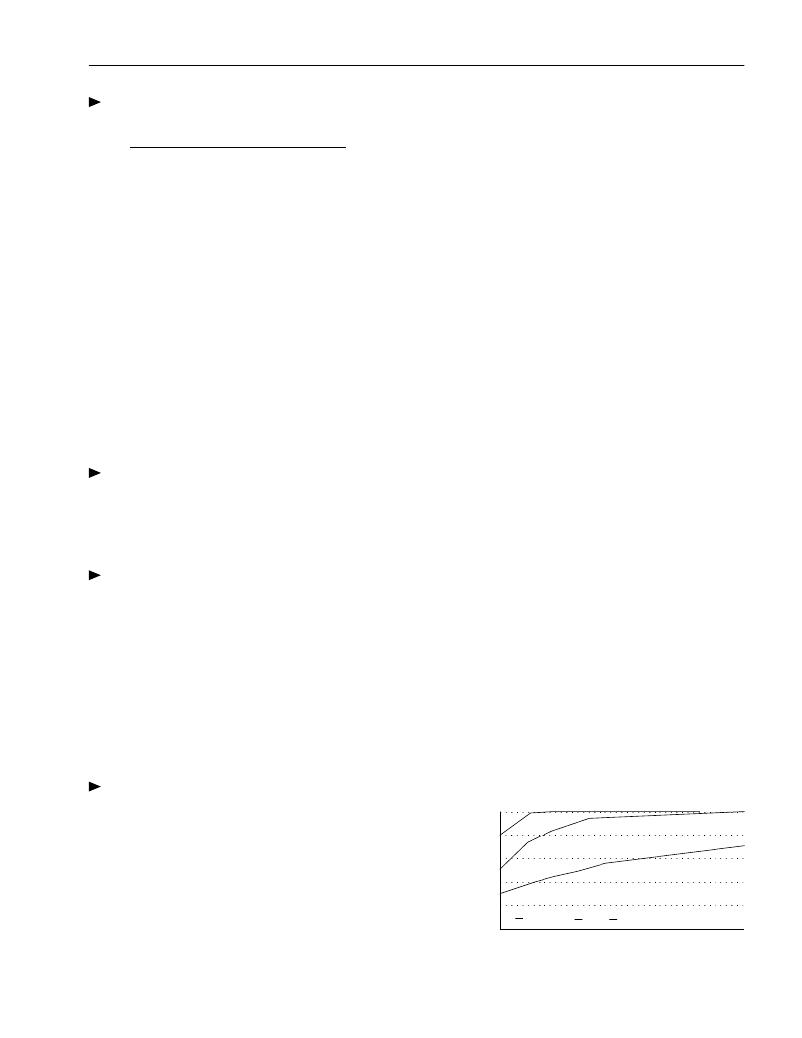

�Time:� After� application,� the� bond� strength� will� increase� as�

�Bond� Typical� Build� vs.� Time�

�●�

�★�

�★�

�●�

�●�

�the� adhesive� flows� onto� the� surface� (also� referred� to� as� “wet� out”).�

�At� room� temperature� approximately� 50%� of� ultimate� bond�

�strength� will� be� achieved� after� 20� minutes,� 90%� after� 24� hours�

�and� 100%� after� 72� hours.� This� flow� is� faster� at� higher� temperatures�

�and� slower� at� lower� temperatures.� Ultimate� bond� strength� can� be�

�achieved� more� quickly� (and� in� some� cases� bond� strength� can� be�

�increased)� by� exposure� of� the� bond� to� elevated� temperatures�

�60�

�20�

�PERCENT� OF� FULL� BOND�

�100� ■� ■� ■�

�■� ●�

�●�

�80� ■� ●�

�●�

�●�

�★�

�40� ★�

�★�

�■�

�●�

�★�

�■�

�●�

�★�

�■�

�●�

�■�

�★�

�■�

�★�

�■�

�★�

�●�

�■� ●�

�★�

�●�

�★�

�●�

�★�

�(e.g.� 150°F� [66°C]� for� 1� hour).� This� can� provide� better� adhesive�

�wetout� onto� the� substrates.� Abrasion� of� the� surfaces� or� the� use� of�

�0�

�20� MIN�

�1� HOUR� 24� HOURS�

�●� ROOM� TEMP� ★� 50°F�

�■� 150°F� or� ABRADE�

�72� HOURS�

�primers/� adhesion� promoters� can� also� have� the� effect� of� increasing�

�bond� strength� and� achieving� ultimate� bond� strength� more� quickly.�

�-9-�

�相关PDF资料 |

PDF描述 |

|---|---|

| OSTYK22304030 | CONN BARRIER STRIP 4CIRC 6.35MM |

| 431701-01-0 | TERM BARRIER 1CIRC SGL ROW .4375 |

| 325348-02-0 | TERM BARRIER 2CIRC SGL ROW .325 |

| 1812L160PR | PTC RESETTBLE 8V 1.60A 1812L SMD |

| 325338-02-0 | TERM BARRIER 2CIRC SGL ROW .325 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 3M-4941-0.500-DISCS | 功能描述:VHB ACRYLIC FOAM CIRCLE.5" 250PC RoHS:是 类别:胶带,粘合剂 >> 带 系列:VHB™ 4941 MSDS 材料安全数据表:2393 MSDS 标准包装:40 系列:Scotch® 2393 胶带类型:屏蔽,高温 胶合剂:橡胶 背衬,载体:绉纸 厚度:0.0076"(7.6 mils,0.193mm) 厚度 - 胶合剂:- 厚度 - 背胶,载体,衬垫:- 宽:1.42"(36.00mm) 长度:180'(55.0m)60 码 颜色:棕褐 使用:喷漆,自动 温度范围:325°F(163°C)- 30 分钟 包装:- 其它名称:000212007130330212007130370006165651 |

| 3M-4941-0.750-DISCS | 功能描述:VHB ACRYLIC FOAM CIRCLE3/4"250PC RoHS:是 类别:胶带,粘合剂 >> 带 系列:VHB™ 4941 MSDS 材料安全数据表:2393 MSDS 标准包装:40 系列:Scotch® 2393 胶带类型:屏蔽,高温 胶合剂:橡胶 背衬,载体:绉纸 厚度:0.0076"(7.6 mils,0.193mm) 厚度 - 胶合剂:- 厚度 - 背胶,载体,衬垫:- 宽:1.42"(36.00mm) 长度:180'(55.0m)60 码 颜色:棕褐 使用:喷漆,自动 温度范围:325°F(163°C)- 30 分钟 包装:- 其它名称:000212007130330212007130370006165651 |

| 3M-4941-1.000-DISCS | 功能描述:VHB ACRYLIC FOAM CIRCLES 1"250PC RoHS:是 类别:胶带,粘合剂 >> 带 系列:VHB™ 4941 MSDS 材料安全数据表:2393 MSDS 标准包装:40 系列:Scotch® 2393 胶带类型:屏蔽,高温 胶合剂:橡胶 背衬,载体:绉纸 厚度:0.0076"(7.6 mils,0.193mm) 厚度 - 胶合剂:- 厚度 - 背胶,载体,衬垫:- 宽:1.42"(36.00mm) 长度:180'(55.0m)60 码 颜色:棕褐 使用:喷漆,自动 温度范围:325°F(163°C)- 30 分钟 包装:- 其它名称:000212007130330212007130370006165651 |

| 3M-4941-1.500-DISCS | 功能描述:VHB ACRYLIC FOAM CIRCLE1.5"100PC RoHS:是 类别:胶带,粘合剂 >> 带 系列:VHB™ 4941 标准包装:1 系列:- 胶带类型:标记 - 印有“无铅区域”字样 胶合剂:- 背衬,载体:- 厚度:- 厚度 - 胶合剂:- 厚度 - 背胶,载体,衬垫:- 宽:1.00"(25.40mm) 长度:360'(109.7m)120 码 颜色:白色字符,绿色背景 使用:标记 温度范围:- 包装:卷 |

| 3M-4941-2.000-DISCS | 功能描述:VHB ACRYLIC FOAM CIRCLES 2"100PC RoHS:是 类别:胶带,粘合剂 >> 带 系列:VHB™ 4941 MSDS 材料安全数据表:2393 MSDS 标准包装:40 系列:Scotch® 2393 胶带类型:屏蔽,高温 胶合剂:橡胶 背衬,载体:绉纸 厚度:0.0076"(7.6 mils,0.193mm) 厚度 - 胶合剂:- 厚度 - 背胶,载体,衬垫:- 宽:1.42"(36.00mm) 长度:180'(55.0m)60 码 颜色:棕褐 使用:喷漆,自动 温度范围:325°F(163°C)- 30 分钟 包装:- 其它名称:000212007130330212007130370006165651 |

发布紧急采购,3分钟左右您将得到回复。