参数资料

| 型号: | 4950-1/2"X36YD-SMPK |

| 厂商: | 3M |

| 文件页数: | 7/11页 |

| 文件大小: | 0K |

| 描述: | TAPE ACRYLC FOAM .045" 1/2"X36YD |

| 视频文件: | Biffle and the 3M Pit Bulls vs. 3M 3M VHB adhesive demonstration - Another Geek Moment |

| MSDS 材料安全数据表: | 49zz MSDS |

| 标准包装: | 4 |

| 系列: | VHB™ 4950 |

| 胶带类型: | 双涂层,双面 |

| 胶合剂: | 丙烯酸 |

| 背衬,载体: | 纸 |

| 厚度: | 0.045"(45 mils,1.143mm) |

| 厚度 - 胶合剂: | 0.042"(42 mils,1.067mm) |

| 厚度 - 背胶,载体,衬垫: | 0.0030"(3.0 mils,0.076mm) |

| 宽: | 0.50"(12.70mm)1/2" |

| 长度: | 108'(32.9m)36 码 |

| 颜色: | 白 |

| 使用: | 通用 |

| 温度范围: | 200°F(93°C) |

| 包装: | 散装 |

| 其它名称: | 3M5625 70006147675 |

�� �

�

�

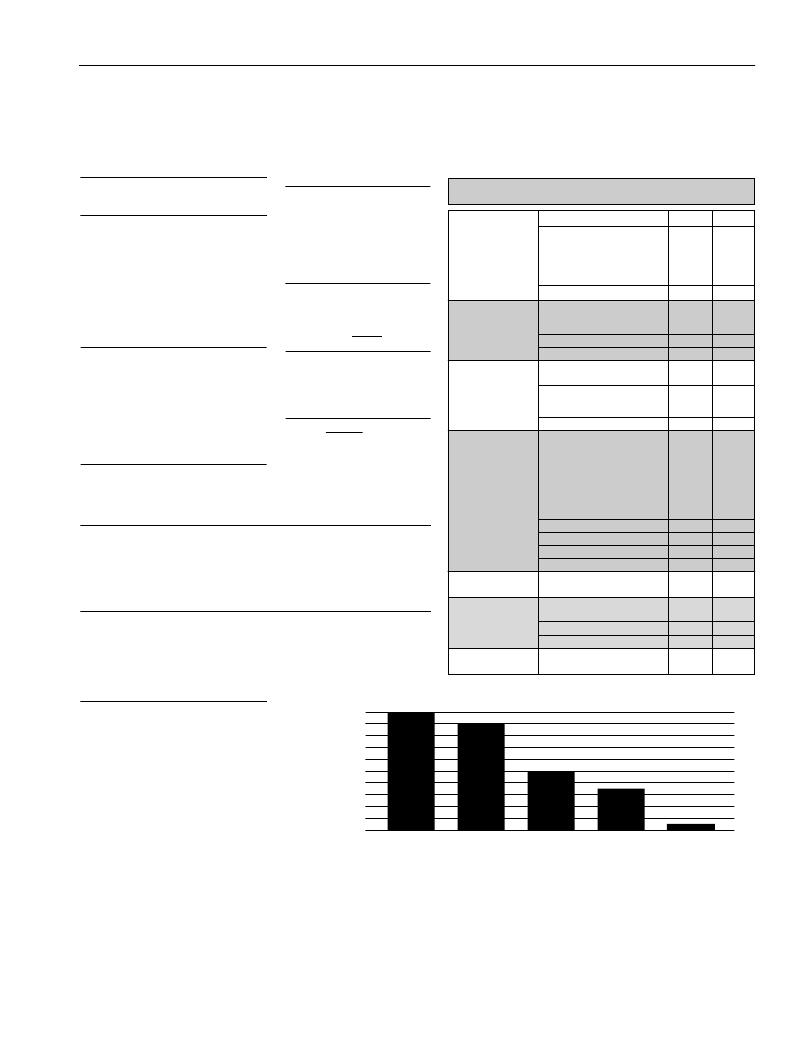

�3M� ?� VHB� ?� Tapes�

�Additional� Typical� Performance� Characteristics�

�Note:� The� following� technical� information� and� data� should� be� considered� representative� or� typical� only� and� should� not�

�be� used� for� specification� purposes.�

�Aluminum,� Galvanized� steel,� stainless�

�-35°C�

�90°C�

�steel,� enameled� steel,� nickel� coated�

�ABS,� glass� (with� or� without� silane�

�Outgassing:�

�3M?� VHB?�

�Tapes� %� TML� %VCM�

�4930� 0.77� 0.01�

�4932� 2.41� 0.66�

�4945� 1.24� 0.01�

�TML� -� Total� Mass� Loss�

�VCM� -� Volatile� Condensible� Materials�

�WVR� -� Water� Vapor� Regained�

�%WVR�

�0.21�

�0.23�

�0.19�

�Dielectric� Breakdown� Strength�

�(ASTM� D149)�

�3M?� VHB?�

�Tapes (in volts/mil)�

�4941� 360�

�4926� 330�

�5952� 455�

�5925� 520�

�4950� 460�

�4920� 640�

�3M?� VHB?� Tapes�

�UL746C� Listings� -� File� MH� 17478�

�Category� QOQW2� Component� -� Polymeric� Adhesive� Systems,� Electrical� Equipment�

�3M?� VHB?� Tapes/� Temperature� Rating�

�Product� Families� Substrates� Minimum� Maximum�

�4919F,� 4926,� 4936,� Ceramic� -35°C� 110°C�

�4936F,� 4941,� 4941F,�

�4947F,� 4956,� 4956F,�

�4979F�

�NASA� Reference� Publication,� “Outgassing� Data�

�for� Selecting� Spacecraft� Materials”,� (11/18/2004)�

�Available� online� at� http://outgassing.nasa.gov�

�4910�

�4611�

�630�

�330�

�coating)� PVC,� glass/epoxy,� PBT,�

�polycarbonate,� acrylic/polyurethane�

�paint,� polyester� paint�

�ABS�

�-35°C�

�75°C�

�Dielectric� Constant�

�(ASTM� D150)�

�Thermal� Conductivity� -� K-value�

�4914,� 4920,� 4930,� 4950�

�Aluminum,� galvanized� steel,�

�enameled� steel,� stainless� steel,�

�-35°C�

�110°C�

�3M?� VHB?�

�Tapes�

�Dielectric�

�Constant�

�Dissipation�

�Factor�

�3M?� VHB?�

�Tapes�

�BTU in/�

�hr� ft� 2� °F�

�(w/mK)�

�ceramic,� glass/epoxy�

�PBT,� Acrylic�

�-35°C�

�90°C�

�4941� at� 1� kHz�

�at� 1� MHz�

�5952� at� 1� kHz�

�at� 1� MHz�

�4950� at� 1� kHz�

�2.29�

�1.99�

�2.14�

�1.95�

�2.28�

�0.0245�

�0.0374�

�0.0065�

�0.0506�

�0.0227�

�4941�

�5952�

�4950/4945�

�4910�

�0.53�

�0.37�

�0.63�

�1.09�

�(0.08)�

�(0.05)�

�(0.09)�

�(0.16)�

�4945,� 4946�

�ABS,� Polycarbonate,� Rigid� PVC�

�Phenolic,� aluminum,� galvanized�

�steel,� alkyd� enamel�

�ABS,� polycarbonate,� polyimide,�

�stainless� steel,� acrylic/polyurethane�

�-35°C�

�-35°C�

�-35°C�

�75°C�

�110°C�

�90°C�

�at� 1� MHz�

�1.99�

�0.0370�

�4611�

�0.77�

�(0.11)�

�paint,� polyester� paint�

�4910� at� 1� kHz�

�at� 1� MHz�

�4611� at� 1� kHz�

�at� 1� MHz�

�Resistivity�

�(ASTM� D257)�

�3.21�

�2.68�

�2.80�

�2.43�

�0.0214�

�0.0595�

�0.0130�

�0.0564�

�R-Value� =� thickness�

�K-value�

�(When� units� of� K-value� are�

�BTU-in/hr� ft� 2� °F� and� thickness�

�is� given� in� inches.)�

�5915,� 5915P,� 5925,�

�5925P,� 5930,� 5930P,�

�5952,� 5952P� 5962,�

�5962P�

�unplasticized� PVC�

�Polycarbonate,� Primer� 94� coated�

�polycarbonate,� aluminum,� acrylic/�

�polyurethane� paint,� galvanized� steel,�

�steel,� polyester� paint,� epoxy/polyester�

�paint,� epoxy� paint,� glass� (with� or�

�without� silane� coating),� stainless�

�steel,� enameled� steel,� glass� epoxy,�

�-35°C�

�-35°C�

�75°C�

�90°C�

�3M?� VHB?�

�Tapes�

�Volume� Resistivity�

�(in� ohm-cm)�

�Surface� Resistance�

�(in� ohms/square)�

�polybutylene� terephthalate,� Nylon� ?� ,�

�Noryl� ?� (PPE)� polyphenenlene� ether�

�4914�

�4941�

�5952�

�4950�

�4920�

�1.7� x� 10� 11�

�2.1� x� 10� 14�

�2.5� x� 10� 14�

�1.5� x� 10� 15�

�1.7� x� 10� 15�

�>10� 16�

�2.7� x� 10� 14�

�>10� 16�

�>10� 16�

�>10� 16�

�5915,� 5925,� 5930,� 5952�

�5962�

�5952�

�4991�

�Rigid� PVC,� ABS�

�Acrylic�

�Acrylic�

�Cellulose� Acetate� Butyrate�

�Polycarbonate,� aluminum,� acrylic/�

�-35°C�

�-35°C�

�-35°C�

�-35°C�

�-35°C�

�75°C�

�90°C�

�80°C�

�90°C�

�90°C�

�4910�

�3.1� x� 10� 15�

�>10� 16�

�polyurethane� paint,� polyester� paint�

�4611�

�1.4� x� 10� 15�

�>10� 16�

�4611,� 4646,� 4655�

�Stainless� steel,� aluminum,� galvanized�

�-35°C�

�110°C�

�steel,� glass,� glass/epoxy,� phenolic�

�Water� Vapor� Transmission� Rate� (WVTR)�

�(ASTM� F1249)� at� 38°C/100%� RH�

�Nylon,� polycarbonate�

�ABS,� rigid� PVC�

�-35°C�

�-35°C�

�90°C�

�75°C�

�3M?� VHB?� Tapes�

�4905,� 4910�

�Polycarbonate,� aluminum,�

�-35°C�

�90°C�

�4950�

�4941�

�5952�

�14.0� g/(m� 2� day)�

�25.6� g/(m� 2� day)�

�37.1� g/(m� 2� day)�

�acrylic/polyurethane� paint�

�A� current� list� can� be� found� at� www.ul.com� (select� certifications,� search� file� MH17478)�

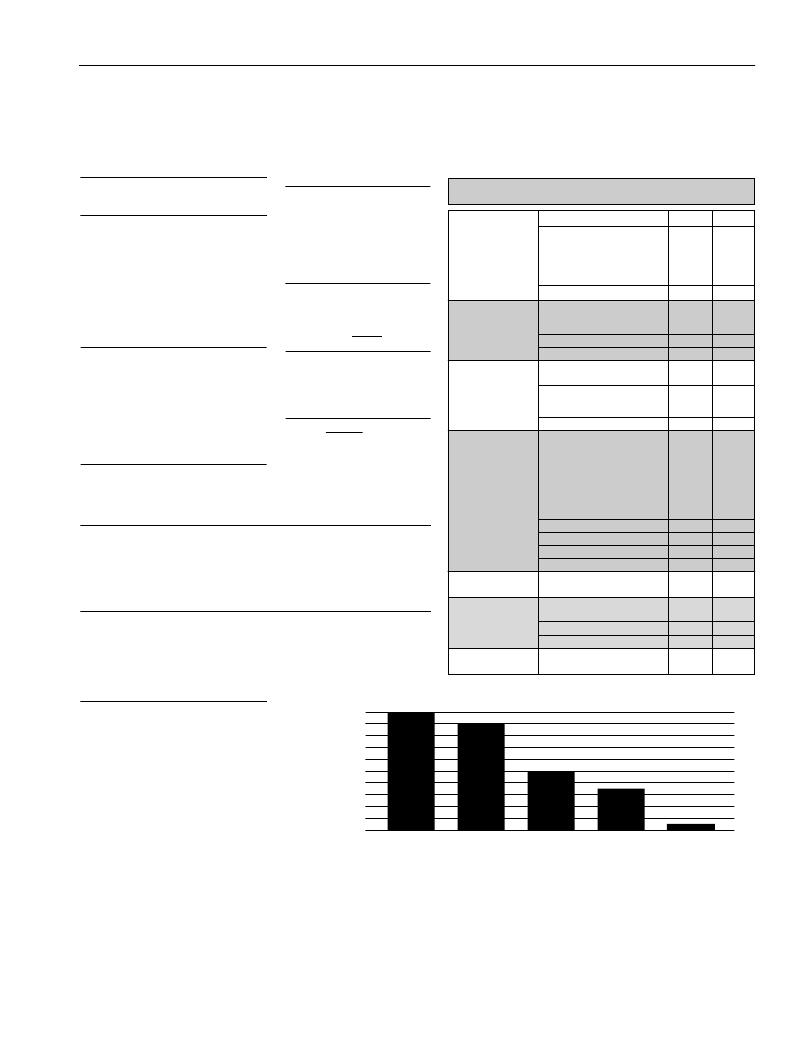

�Solvent� and� Fuel� Resistance�

�100�

�100�

�Typical� 3M?� VHB?� Tape� Properties� for� Modeling�

�Thermal� Coefficient�

�of� Expansion�

�1� x� 10� -4� in/in/°F�

�1.8� x� 10� -4� mm/mm/°C�

�Shear� Modulus� (@25°C,� 1� Hz)�

�4950� Family:� 6� x� 10� 5� Pa�

�4941� Family:� 3� x� 10� 5� Pa�

�(Shear� Modulus� is� both� temperature� and� frequency�

�dependent).�

�%�

�A�

�d�

�h�

�e�

�s�

�i�

�v�

�e�

�R�

�e�

�t�

�e�

�n�

�t�

�i�

�o�

�n�

�90�

�80�

�70�

�60�

�50�

�40�

�30�

�20�

�10�

�0�

�Water�

�Kerosene�

�Isopropyl� Alcohol�

�Gasoline�

�MEK�

�90�

�80�

�70�

�60�

�50�

�40�

�30�

�20�

�10�

�0�

�Youngs� Modulus:� For� VHB� tapes� the� Youngs�

�Modulus� will� be� about� 3� times� the� Shear� Modulus.�

�Poisson’s� Ratio�

�0.49�

�Salt� Water�

�Hydraulic� Fluid�

�10W30� Motor� Oil�

�Glycol� Antifreeze�

�Test� Method�

�?� Tape� between� stainless� steel� and� aluminum� foil.�

�?� 72� hours� dwell� at� room� temperature.�

�Jet� Fuel�

�Burn� Characteristics� 3M?� VHB?� Tape� 5958FR�

�Meets� FAR� 25.853� (a)� 12� second� vertical� burn,�

�Appendix� F,� Part� I� (a)(ii).�

�Meets� NBS� Smoking� Density� (ASTM� F814/E662).�

�Meets� Toxicity� (Draeger� Tube� ABD0031,� AITM�

�3.0005)�

�?� Solvent� immersion� for� 72� hours.�

�?� Test� within� 45� minutes� after� removing� from� solvent.�

�?� 90°� peel� angle.�

�?� 12� in./min.� rate� of� peel.�

�?� Peel� adhesion� compared� to� control.�

�Note:� Continuous� submersion� in� chemical� solutions� is� not� recommended.� The� above� information� is� presented� to� show� that�

�occasional� chemical� contact� should� not� be� detrimental� to� tape� performance� in� most� applications� in� ordinary� use.�

�-7-�

�相关PDF资料 |

PDF描述 |

|---|---|

| 0395133906 | 3.81MM EURO PLUG STR BLK 6POS |

| 0395133806 | 3.81MM EURO PLUG STR BLK 6POS |

| 0395132906 | 3.81MM EURO PLUG STR BLK 6POS |

| 5-640426-3 | CONN RECEPT 23POS 18AWG MTA156 |

| 0395132806 | 3.81MM EURO PLUG STR BLK 6POS |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 495013 | 制造商:CK tools 功能描述:TIP 25W 制造商:CK tools 功能描述:TIP, 25W |

| 495014 | 制造商:CK tools 功能描述:TIP 40W |

| 495015 | 制造商:Ck Tools 功能描述:Bulk 制造商:CK tools 功能描述:UNIVERSAL CROSS KEY 制造商:CK TOOLS 功能描述:UNIVERSAL CROSS KEY; SVHC:No SVHC (19-Dec-2012) ;RoHS Compliant: NA |

| 4950-1x36 | 功能描述:胶带 4950 1 X 36 YD BULK RoHS:否 制造商:3M Electronic Specialty 产品:Tapes 类型:Shielding 描述/功能:EMI/RFI Foil Shielding Tape 颜色: 材料:Copper Foil 宽度:1 in x 18 yds |

| 4950-1X36YD-SMPK | 制造商:3M Electronic Products Division 功能描述:70006147691 |

发布紧急采购,3分钟左右您将得到回复。