参数资料

| 型号: | 4952G |

| 厂商: | Aavid Thermalloy |

| 文件页数: | 13/116页 |

| 文件大小: | 0K |

| 描述: | THERMAL EPOXY |

| MSDS 材料安全数据表: | 4952A THERMALBOND MSDS 4952B THERMALBOND MSDS |

| 标准包装: | 1 |

| 系列: | Thermalbond™ |

| 类型: | 环氧树脂硬化剂 |

| 尺寸/尺寸: | 7 盎司包装 |

| 其它名称: | 033870 |

第1页第2页第3页第4页第5页第6页第7页第8页第9页第10页第11页第12页当前第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页第37页第38页第39页第40页第41页第42页第43页第44页第45页第46页第47页第48页第49页第50页第51页第52页第53页第54页第55页第56页第57页第58页第59页第60页第61页第62页第63页第64页第65页第66页第67页第68页第69页第70页第71页第72页第73页第74页第75页第76页第77页第78页第79页第80页第81页第82页第83页第84页第85页第86页第87页第88页第89页第90页第91页第92页第93页第94页第95页第96页第97页第98页第99页第100页第101页第102页第103页第104页第105页第106页第107页第108页第109页第110页第111页第112页第113页第114页第115页第116页

11

READING

A

T

HERMAL

PERFORMANCE

GR

APH

EUROPE

ASIA

Italy Tel: +39 051 764011 email: sales.it@aavid.com

United Kingdom Tel: +44 1793 401400 email: sales.uk@aavid.com

Singapore Tel: +65 6362 8388 email: sales@aavid.com.sg

Taiwan Tel: +886(2) 2698-9888 email: sales@aavid.com.tw

AMERICA

USA Tel: +1 (603) 224-9988 email: info@aavid.com

www.aavidthermalloy.com

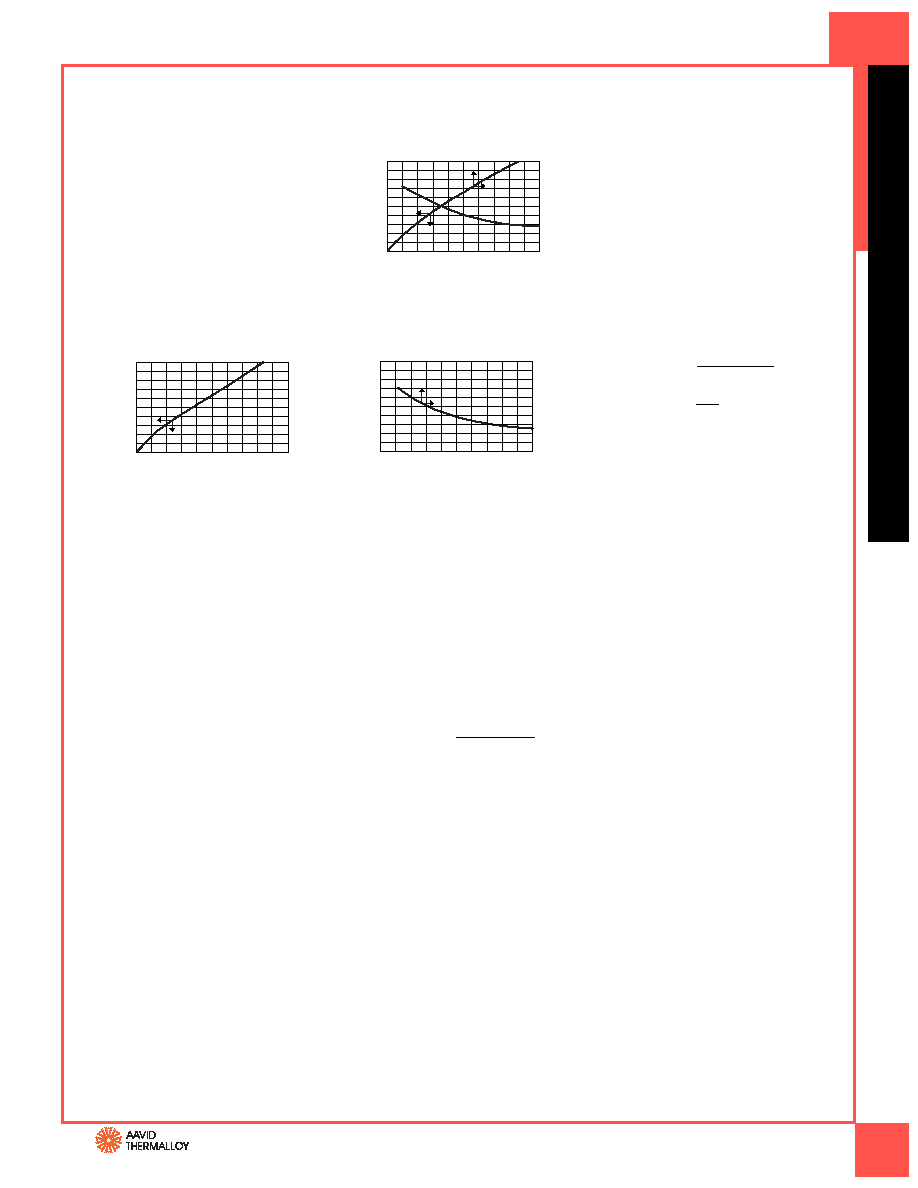

The performance graphs you will see in this

catalog (see graph 579802) are actually a

composite of two separate graphs which

have been combined to save space. The small

arrows on each curve indicate to which axis

the curve corresponds. Thermal graphs are

published assuming the device to be cooled

is properly mounted and the heat sink is in

its recommended mounting position.

GRAPH A is used to show heat sink perform-

ance when used in a natural convection envi-

ronment (i.e. without forced air). This graph

starts in the lower left hand corner with the

horizontal axis representing the heat dissipa-

tion (watts) and the vertical left hand axis

representing the rise in heat sink mounting

surface temperature above ambient (°C). By

knowing the power to be dissipated, the

temperature rise of the mounting surface

can be predicted. Thermal resistance in natu-

ral convection is determined by dividing this

temperature rise by the power input (°C/W).

EXAMPLE A: Aavid Thermalloy part number

579802 is to be used to dissipate 3 watts of

power in natural convection. Because we are

dealing with natural convection, we refer to

graph “A”. Knowing that 3 watts are to be dis-

sipated, follow the grid line to the curve and

find that at 3 watts there is a temperature

rise of 75°C. To get the thermal resistance,

divide the temperature rise by the power

dissipated, which yields 25°C/W.

GRAPH B is used to show heat sink per-

formance when used in a forced convec-

tion environment (i.e. with forced air flow

through the heat sink). This graph has its

origin in the top right hand corner with

the horizontal axis representing air velocity

over the heat sink LFM* and the vertical

axis representing the thermal resistance of

the heat sink (°C/W). Air velocity is calculat-

ed by dividing the output volumetric flow

rate of the fan by the cross-sectional area

of the outflow air passage.

EXAMPLE B: For the same application

we add a fan which blows air over the heat

sink at a velocity of 400 LFM.

The addition of a fan indicates the use of

forced convection and therefore we refer

to graph “B”. This resistance of 9.50°C/W is

then multiplied by the power to be dissi-

pated, 3 watts. This yields a temperature

rise of 28.5°C.

CONVERTING VOLUME

TO VELOCITY

Although most fans are normally rated and

compared at their free air delivery at zero

back pressure, this is rarely the case in most

applications. For accuracy, the volume of

output must be derated 60%–80% for

the anticipation of back pressure.

EXAMPLE: The output air volume

of a fan is given as 80 CFM. The output area

is 6 inches by 6 inches or 36 in2 or 25 ft2.

To find velocity:

80

0.25

Velocity is 320 LFM, which at 80%,

derates to 256 LFM.

DESIGN ASSISTANCE

Aavid Thermalloy can assist in the design

of heat sinks for both forced and natural

convection applications. Contact us for help

with your next thermal challenge. For more

information, visit our web site at:

www.aavidthermalloy.com

Heat Dissipated—Watts

0

20

40

60

80

100

01

2

3

4

5

Mounting

Surface

Temp

Rise

Above

Ambient—

°

C

Air Velocity—Feet Per Minute

Thermal

Resistance

From

MTG

Surface

to

Ambient—

°

C/Watt

20

16

12

4

8

0

400

200

600

800

1000

GRAPH B

Velocity (LFM) =

Velocity =

= 320

Air Velocity—Feet Per Minute

Heat Dissipated—Watts

Thermal

Resistance

From

MTG

Surface

to

Ambient—

°

C/Watt

20

0

20

40

60

80

100

01

2

3

4

5

16

12

4

8

0

400

200

600

800

1000

Mounting

Surface

Temp

Rise

Above

Ambient—

°

C

GRAPH A

579802

Reading a Thermal Performance Graph

Velocity

(LFM)* = Volume (CFM)**

area (ft2)

* Linear feet per minute

** Cubic feet per minute

Volume (CFM)

area (ft2)

相关PDF资料 |

PDF描述 |

|---|---|

| WM093RC,AL | WALLMNT ENCLOSURE 9.50X6.34X2.10 |

| AE40A-50-ND | CABLE 40COND GRAY 50' RIBBON |

| 102100F00000G | THERMAL GREASE |

| H11F3SM | OPTOCOUPLER PHOTO FET 6SMD |

| AE50G-50-ND | CABLE 50 COND 50' GRAY RIBBON |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 4952P | 制造商:3M Electronic Products Division 功能描述: |

| 4952-WHITE-1"X36YD | 功能描述:TAPE VHB ACRYLIC FOAM 1"X 36YD RoHS:是 类别:胶带,粘合剂 >> 带 系列:VHB™ 4952 MSDS 材料安全数据表:42x, 43x, 140x, 141x, 1449, 1450, 433,438,33xx MSDS 标准包装:1 系列:425 胶带类型:铝箔 胶合剂:丙烯酸 背衬,载体:铝,极软的 厚度:0.0046"(4.6 mils,0.117mm) 厚度 - 胶合剂:0.0016"(1.6 mils,0.041mm) 厚度 - 背胶,载体,衬垫:0.0028"(2.8 mils,0.071mm) 宽:2.00"(50.80mm) 长度:15'(4.6m)5 码 颜色:银 使用:热耗散,反射 温度范围:-65 ~ 300°F(-54 ~ 149°C) 包装:散装 工具箱:3M10454-ND - MRO TAPE KIT - PREMIUM3M10451-ND - MRO TAPE KIT - STANDARDTK3434-ND - HOME TAPE KIT - PREMIUM3M10395-ND - DESIGN ENGR SOLUTION SEMINAR KIT3M10394-ND - DESIGN ENGR METAL FOIL TAPE KIT 其它名称:3M9778 |

| 4952-WHITE-1/2"X36YD | 功能描述:TAPE VHB ACRYLIC FOAM 1/2"X 36YD RoHS:是 类别:胶带,粘合剂 >> 带 系列:VHB™ 4952 MSDS 材料安全数据表:42x, 43x, 140x, 141x, 1449, 1450, 433,438,33xx MSDS 标准包装:1 系列:425 胶带类型:铝箔 胶合剂:丙烯酸 背衬,载体:铝,极软的 厚度:0.0046"(4.6 mils,0.117mm) 厚度 - 胶合剂:0.0016"(1.6 mils,0.041mm) 厚度 - 背胶,载体,衬垫:0.0028"(2.8 mils,0.071mm) 宽:2.00"(50.80mm) 长度:15'(4.6m)5 码 颜色:银 使用:热耗散,反射 温度范围:-65 ~ 300°F(-54 ~ 149°C) 包装:散装 工具箱:3M10454-ND - MRO TAPE KIT - PREMIUM3M10451-ND - MRO TAPE KIT - STANDARDTK3434-ND - HOME TAPE KIT - PREMIUM3M10395-ND - DESIGN ENGR SOLUTION SEMINAR KIT3M10394-ND - DESIGN ENGR METAL FOIL TAPE KIT 其它名称:3M9778 |

| 4952-WHITE-1/2X36YD | 制造商:3M Electronic Products Division 功能描述: |

| 4953 | 功能描述:速度传感器 ATOM & PROX RoHS:否 制造商:Honeywell 最大工作温度:+ 120 C 电源电压: 电源电流: 输出电压:190 V 工作电源电压: 安装风格:Screw 最小工作温度:- 55 C 系列:High Output VRS |

发布紧急采购,3分钟左右您将得到回复。