- 您现在的位置:买卖IC网 > PDF目录18956 > 701-M (3M)MEGOHMMETER PDF资料下载

参数资料

| 型号: | 701-M |

| 厂商: | 3M |

| 文件页数: | 4/8页 |

| 文件大小: | 0K |

| 描述: | MEGOHMMETER |

| 标准包装: | 1 |

| 系列: | 701 |

| 工具类型: | 兆欧表 |

| 相关产品: | 701-W-ND - TEST WEIGHT 5 LBS |

| 其它名称: | 0-00-54007-49308-2 00054007493082 05400749308 701-M-ND 701M 98-0798-2290-8 98079822908 SCP428 |

OFF

10V

100V

BATTERY

TEST

CONTINUITY

TEST

READ MANUAL BEFORE USE

OHMS

SURFACE

TEST

TAUT

BAND

SUSPENSION

10

9

1G

10G

FAIL

PASS

10

11

100G

10

8

10

7

10

6

10

5

0

1M

100K

0

10M

100M

CONTINUITY

BATTERY

100V

0

10K

100K

1M

10M

100M

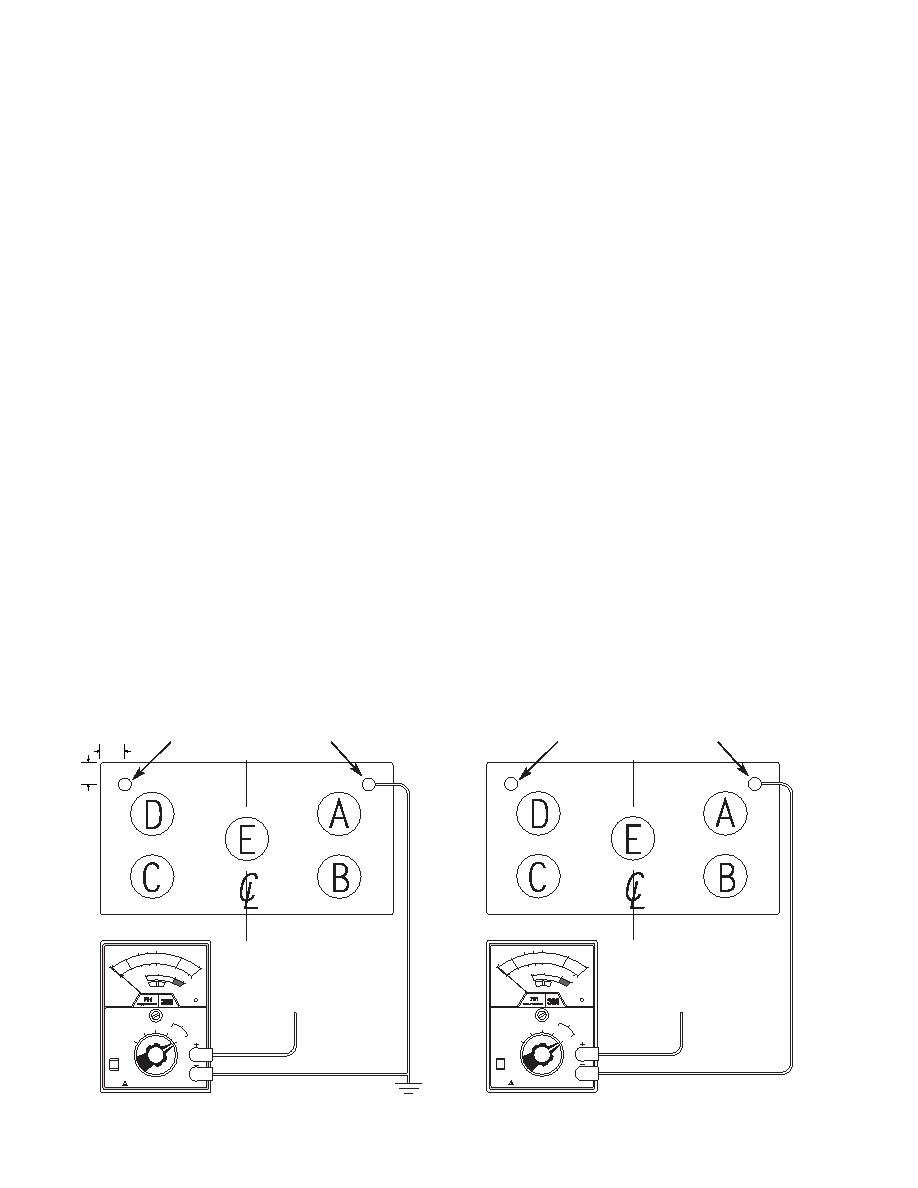

Figure 5-1: Periodic Performance Tests of Installed Surfaces

OFF

10V

100V

BATTERY

TEST

CONTINUITY

TEST

READ MANUAL BEFORE USE

OHMS

SURFACE

TEST

TAUT

BAND

SUSPENSION

10

9

1G

10G

FAIL

PASS

10

11

100G

10

8

10

7

10

6

10

5

0

1M

100K

0

10M

100M

CONTINUITY

BATTERY

100V

0

10K

100K

1M

10M

100M

Figure 5-2: Qualification Tests of Installed Surfaces

3

STATIC CONTROL SURFACE

GROUNDABLE POINTS

TO TEST WEIGHT AT TEST

POINT A, B, C, D & E

TO TEST WEIGHT AT TEST

POINT A, B, C, D & E

2”

STATIC CONTROL SURFACE

GROUNDABLE POINTS

drain a static charge in a reasonable time. This test

involves measurement of the total resistance from the

static control surface through the conductor or ground

cord to the ESD GROUND (ESDG), verifying that the

entire static control system is functioning correctly.

NOTE: ESD-S4. 1 suggests that a static control surface that

measures in the range of 1x10

6 ohms to 1x1010 ohms RTS-

ESDG is acceptable. HOWEVER, 3M RECOMMENDS THAT A

MORE CONSERVATIVE VALUE OF 1X10

9 OHMS BE USED AS

THE HIGHEST ACCEPTABLE RESISTANCE TO ESD GROUND.

The following procedures should be followed when

testing installed static control surfaces.

A. Complete BATTERY TEST and CONTINUITY TEST.

B. Set the Instrument on a table top or other stable surface

and place a test weight at the desired test point as shown

in Figure 5-1. Connect the test leads to the meter using

the right angle banana plugs at the meter. Then connect

one of the test leads to the test weight and the other to

the ESD GROUND using one of the supplied clips.

C. Test the static control surface using the 100 volts

SURFACE TEST. Depress the TEST button for 15

seconds, allowing the pointer to stabilize; record the

readings for each test point. If the reading is below 1x10

6

ohms, check the static control surface for an alternate

path to ground; correct and retest. If some or all the

readings are above 1x10

9 ohms, the static control surface

may be dirty. Clean the surface using the manufacturer’s

recommended cleaning procedure followed by two

clear water rinses and a rinse with 70% Isopropyl

alcohol. Allow the surface to dry overnight and retest.

If the resistance reading is “infinite,” there is an

interruption (open) in the ground connection; repair

and retest.

2. QUALIFICATION OF INSTALLED STATIC

CONTROL SURFACES

[Measurement of resistance of the top surface to the

groundable point of the static control surface (RTS-GP)].

GROUNDABLE POINT is the point at which the

grounding conductor is connected to the static control

surface; the GROUNDABLE POINT is most commonly

a snap (mats), a bolt (laminate), or a strip of conductive

foil tape (flooring). This QUALIFICATION

measurement is similar to those described in the test

description section and is used to verify the correct

installation of the GROUNDABLE POINT by the

manufacturer or by the user. While the test procedure is

the same, the test setup is slightly different; see Figure 5-2.

3. EVALUATION OF STATIC CONTROL

MATERIALS

[Measurement of the resistance between two points on

top of a static control surface (RTS-TS), and the resistance

between a point on the surface and the groundable point

(RTS-GP)]: Material measurements are done to determine

the intrinsic electrical properties of static control work

surface materials.

NOTE: Values obtained by these tests may not reflect how a

material will perform when installed as a static control surface.

Material evaluations are typically done at two humidities

(12% RH and 50% RH) to determine whether the

electrical properties of the material are humidity-

dependent. If the low humidity test results are borderline

or not within the expected ranges, caution should be

exercised when using such materials in winter months or

in dry conditions. To assure test accuracy, a minimum of

six samples should be tested. The test procedure is as

follows:

A. Prepare a minimum of six samples of each material

to be tested as shown in Figure 5-3.

B. Clean samples to be tested with a 70% Isopropyl alcohol

solution and condition at 73°F (23°C) and 50% RH for

48-72 hours.

NOTE: Samples must be maintained at the appropriate humidity

level throughout the test procedures.

C. Complete BATTERY TEST and CONTINUITY TEST

相关PDF资料 |

PDF描述 |

|---|---|

| MAX6610AUT+T | IC TEMP SENSOR LP SOT23-6 |

| CSX750FBC25.000M-UT | OSCILLATOR 25.0000 MHZ SMD |

| MAX6673AXK+T | IC TEMP SENSOR PWM OUT SC70-5 |

| DS18S20+PAR | IC THERM MICROLAN HI-PREC TO-92 |

| 7C-40.000MCB-T | OSCILLATOR 40.000 MHZ 2.5V SMD |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 701-MAT SZ7 | 制造商:BM POLYCO 功能描述:MATRIX D GRIP 7 NYLON/DOTTED WHITE |

| 701-MD | 制造商:Marinco Electrical Group 功能描述: |

| 701P7R-104 | 功能描述:HOURMETER 4.5-15VDC BKLT W/RESET RoHS:是 类别:工业控制,仪表 >> 仪表 - 小时 系列:700 其它有关文件:Declaration of Conformity 标准包装:1 系列:CHG48 显示器类型:- 电压 - 额定:24 ~ 30VAC 特点:无复位 封装/外壳:面板安装 |

| 701P7R-114 | 功能描述:HOURMETER 9-60VDC BKLT W/RESET RoHS:是 类别:工业控制,仪表 >> 仪表 - 小时 系列:700 其它有关文件:Declaration of Conformity 标准包装:1 系列:CHG48 显示器类型:- 电压 - 额定:24 ~ 30VAC 特点:无复位 封装/外壳:面板安装 |

| 701PB542 | 功能描述:按钮开关 UNSEALED OI RoHS:否 制造商:C&K Components 触点形式:2 NC - 2 NO 开关功能:ON ? OFF 电流额定值:4 A 电压额定值 AC:12 V to 250 V 电压额定值 DC:12 V to 50 V 功率额定值: 安装风格:Through Hole 照明:Illuminated 照明颜色:None IP 等级:IP 40 端接类型:Solder 触点电镀:Silver 执行器:Square 盖颜色: 封装: 可燃性等级:UL 94 V-0 |

发布紧急采购,3分钟左右您将得到回复。