- 您现在的位置:买卖IC网 > Datasheet目录393 > AMS104Y (Panasonic Electric Works)SENSOR LIGHT NAPICA 5V SMT 4SOP Datasheet资料下载

参数资料

| 型号: | AMS104Y |

| 厂商: | Panasonic Electric Works |

| 文件页数: | 4/6页 |

| 文件大小: | 0K |

| 描述: | SENSOR LIGHT NAPICA 5V SMT 4SOP |

| 产品培训模块: | NaPiCa Visible Light Sensor |

| 产品目录绘图: | AMS104Y AMS104Y Circuit |

| 标准包装: | 1 |

| 带接近传感器: | 无 |

| 波长: | 580nm |

| 电源电压: | 1.5 V ~ 6 V |

| 电流 - 暗(标准): | 300nA |

| 电流 - 光(典型值): | 260µA |

| 输出类型: | 电流 |

| 工作温度: | -30°C ~ 85°C |

| 安装类型: | 表面贴装 |

| 封装/外壳: | 4-SOIC(0.087",2.20mm 宽) |

| 包装: | 标准包装 |

| 产品目录页面: | 2780 (CN2011-ZH PDF) |

�� ��

��

��

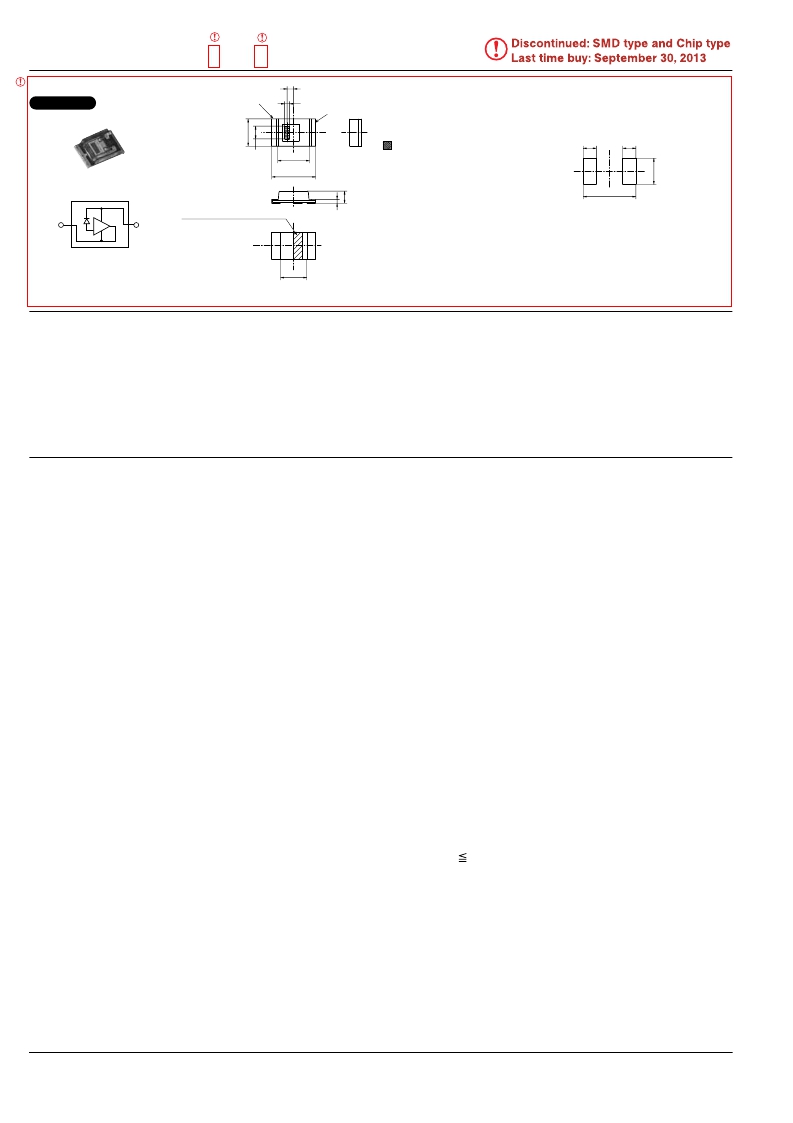

��Light� Sensor� (AMS1,� 3,� 4)�

�3.� Chip� type�

�(0.30)�

�CAD� Data�

�(.012)�

�1�

�1.25�

�.049�

�(0.58)�

�(.023)�

�(0.23)�

�(.009)�

�1.45�

�.057�

�2.0�

�.079�

�2�

�1� Anode�

�2� Cathode�

�DETECTION� AREA�

�Recommended� mounting� pad�

�(Top� view)�

�(0.6)�

�(0.6)�

�(.024)�

�(.024)�

�(1.2)�

�(.047)�

�0.55�

�.022�

�(2.4)�

�(.094)�

�Mark� for� indicating� orientation�

�(0.17)�

�1�

�Amplifier�

�2�

�(.007)�

�1� Anode� (–)�

�2� Cathode� (+)�

�SAFETY� PRECAUTIONS�

�1.2�

�.047�

�General� Tolerance:� ±� 0.1� ±� .004�

�Be� sure� to� obey� the� following� in� order� to�

�prevent� injuries� and� accidents.�

�?� Do� not� use� the� sensors� under�

�conditions� that� exceed� the� range� of� its�

�speci?cations.� It� may� cause�

�overheating,� smoke,� or� ?re.�

�CAUTIONS� FOR� USE�

�1.� Applying� stress� that� exceeds� the�

�absolute� maximum� rating�

�If� the� voltage� or� current� value� for� any� of�

�the� terminals� exceeds� the� absolute�

�maximum� rating,� internal� elements� will�

�deteriorate� because� of� the� excessive�

�voltage� or� current.� In� extreme� cases,�

�wiring� may� melt,� or� silicon� P/N� junctions�

�may� be� destroyed.�

�Therefore� the� design� should� ensure� that�

�the� absolute� maximum� ratings� will� never�

�be� exceeded,� even� momentarily.�

�2.� Deterioration� and� destruction�

�caused� by� discharge� of� static�

�electricity�

�This� phenomenon� is� generally� called�

�static� electricity� destruction.� Static�

�electricity� generated� by� various� factors�

�?ows� through� the� terminal� and� occurs� to�

�destroy� internal� elements.� To� prevent�

�problems� from� static� electricity,� the�

�following� precautions� and� measures�

�should� be� taken� when� using� your� device.�

�1)� Person� handling� sensor� should� wear�

�anti-static� clothing� and� should� be�

�grounded� through� protective� resistance�

�of� 500� k� ?� to� 1� M� ?� .�

�2)� A� conductive� metal� sheet� should� be�

�placed� over� the� work� table.� Measuring�

�instruments� and� jigs� should� be� grounded.�

�3)� When� using� soldering� irons,� either� use�

�irons� with� low� leakage� current,� or� ground�

�the� tip� of� the� soldering� iron.� (Use� of� low-�

�voltage� soldering� irons� is� also�

�recommended.)�

�?� Connect� terminals� correctly� by� verifying�

�the� pin� layout� with� the� speci?cations�

�diagram� or� other� instructions.�

�Erroneous� connections� may� lead� to�

�unexpected� operating� errors,�

�overheating,� smoke,� or� ?re.�

�4)� Devices� and� equipment� used� in�

�assembly� should� also� be� grounded.�

�5)� When� packing� printed� circuit� boards�

�and� equipment,� avoid� using� high-polymer�

�materials� such� as� foam� styrene,� plastic,�

�and� other� materials� which� carry� an�

�electrostatic� charge.�

�6)� When� storing� or� transporting� sensor,�

�the� environment� should� not� be� generated�

�static� electricity� (for� instance,� the�

�humidity� should� be� between� 45� and�

�60%),� and� sensor� should� be� protected�

�using� conductive� packing� materials.�

�3.� Just� after� supplying� voltage,� please�

�note� that� current� in� the� sensor� will� be�

�not� constant� until� internal� circuit�

�stability.�

�4.� Storage�

�The� sensors� are� transparent� plastic�

�packages.� They� are� sensitive� to� moisture�

�and� come� in� moisture-proof� packages.�

�Observe� the� following� cautions� when�

�storing.�

�1)� After� the� moisture-proof� package� is�

�unsealed,� take� the� sensors� out� of� storage�

�as� soon� as� possible� (within� 1� week�

�30� °� C� 86� °� F� /60%� R.H.).�

�2)� If� the� devices� are� to� be� left� in� storage�

�for� a� considerable� period� after� the�

�moisture-proof� package� has� been�

�unsealed,� it� is� recommended� to� keep�

�them� in� another� moisture-proof� bag�

�containing� silica� gel� (within� 3� months� at�

�the� most).�

�?� For� an� impotant� and� serious� application�

�in� terms� of� safety,� add� protection� circuit�

�or� any� other� protection� method.�

�3)� Storage� under� extreme� conditions� will�

�cause� soldering� degradation,� external�

�appearance� defects,� and� deterioration� of�

�the� characteristics.� The� following� storage�

�conditions� are� recommended:�

�?� Temperature:� 0� to� 30� °� C� 32� to� 86� °� F�

�?� Humidity:� Less� than� 60%� R.H.�

�(Avoid� freezing� and� condensing)�

�?� Atomosphere:� No� harmful� gasses� such�

�as� sulfurous� acid� gas,� minimal� dust.�

�*When� mounting� with� solder,� if� thermal�

�stress� is� applied� to� sensors� that� have�

�absorbed� moisture,� the� moisture� will�

�vaporize,� swelling� will� occur,� and� the�

�inside� of� the� package� will� become�

�stressed.� This� may� cause� the� package�

�surface� to� blister� or� crack.� Therefore,�

�please� take� caution� and� observe� the�

�soldering� conditions� in� the� following�

�section.�

�Panasonic� Corporation�

�Automation� Controls� Business� Unit�

�industrial.panasonic.com/ac/e�

�ASCTB242E� 201209-T�

�相关PDF资料 |

PDF描述 |

|---|---|

| AN101101 | SENSOR MAGNET LINEAR ANGULAR POS |

| AN820032 | SENSOR TLAPS WIRE VERSION 360DEG |

| AN920036 | TLAPS SENSOR DL NO MAG 0-90 DEG |

| ANT-125K | ANTENNA RFID COIL 125KHZ |

| ANT-1356M | ANTENNA RFID COIL 13.56MHZ |

相关代理商/技术参数 |

参数描述 |

|---|---|

| AMS104YJ | 制造商:Panasonic Electric Works 功能描述: |

| AMS1051 | 制造商:AMS 制造商全称:AMS 功能描述:The AMS1501 series of adjustable and fixed low dropout voltage regulators are designed to provide 1.5A output current to power the new generation of microprocessors. |

| AMS1053 | 制造商:AMS 制造商全称:AMS 功能描述:The AMS1503 series of adjustable and fixed low dropout voltage regulators are designed to provide 3A output current to power the new generation of microprocessors. |

| AMS1058 | 制造商:AMS 制造商全称:AMS 功能描述:TThhee AMS1508 series of adjustable and fixed low dropout voltage regulators are designed to provide 8A output current to power the new generation of microprocessors. |

| AMS1067 | 制造商:AMS 制造商全称:AMS 功能描述:2A Output Current |

发布紧急采购,3分钟左右您将得到回复。