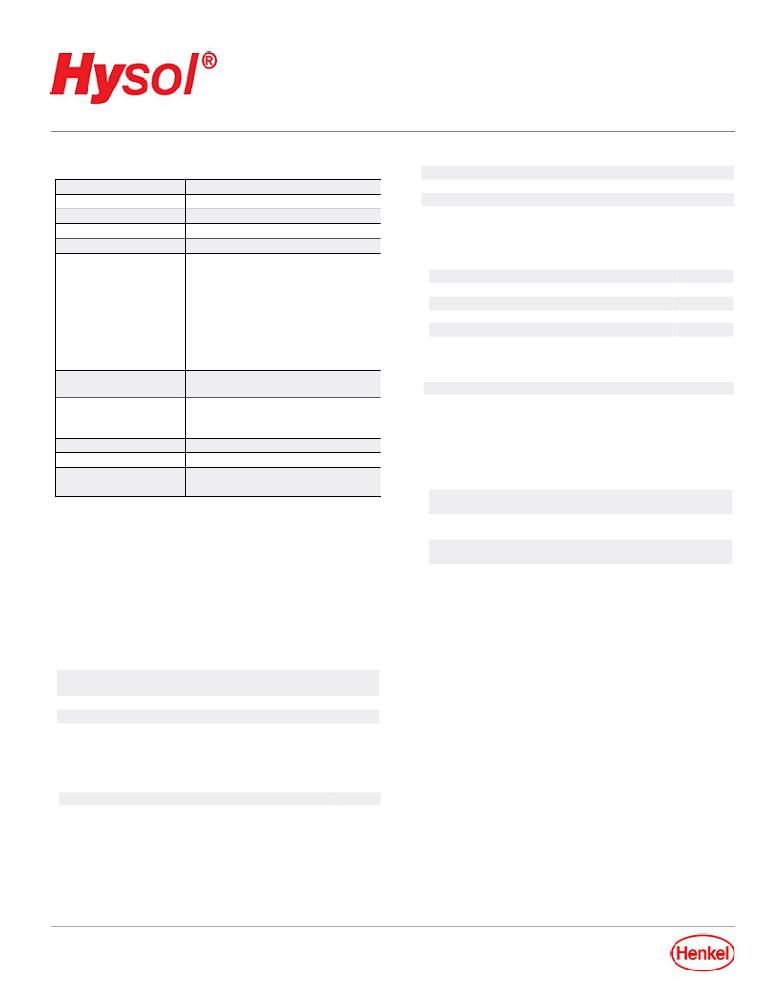

参数资料

| 型号: | BA-2902 |

| 厂商: | Hysol |

| 文件页数: | 1/2页 |

| 文件大小: | 0K |

| 描述: | 2902 ELECTRICALLY CONDUCTIVE ADH |

| MSDS 材料安全数据表: | TRA-DUCT 2902 Hardener MSDS TRA-DUCT 2902 Resin MSDS |

| 标准包装: | 100 |

| 系列: | TRA-DUCT 2902 |

| 类型: | 环氧树脂粘合剂,2 件 |

| 特点: | 热导电 |

| 适用于相关产品: | 密封电子元件 |

| 其它名称: | 999-1003 |

�� �

�

�

�Technical� Data� Sheet�

�TRA-DUCT� 2902�

�June� -� 2010�

�PRODUCT� DESCRIPTION�

�TRA-DUCT� 2902� provides�

�characteristics:�

�Technology�

�Epoxy�

�Appearance�

�Silver�

�Filler� Type�

�Silver�

�the�

�following�

�product�

�TYPICAL� PROPERTIES� OF� CURED� MATERIAL�

�Physical� Properties� :�

�Coefficient� of� Thermal� Expansion,� cm/cm/oC�

�Glass� Transition� Temperature� (Tg),� °C�

�Thermal� Conductivity,� W/mk�

�Hardness,� Shore� D�

�4.9×10� -05�

�52�

�2.99×10� 00�

�80�

�Cure�

�Room� Temperature� or� Heat� Cure�

�Components�

�Product� Benefits�

�Two� component� -� requires� mixing�

�?� Electrically� conductive�

�?� Thermally� conductive�

�?� Solvent-free�

�?� High� adhesion�

�?� Two� component�

�?� Room� temperature� cure�

�Electrical� Properties� :�

�Volume� Resistivity,� ohms-cm:�

�1� hour� @� 110°C�

�15� minutes� @� 150oC�

�2� hours� @� 65oC�

�24� hours� @� 25oC�

�5� minutes� @� 160oC�

�0.0006�

�0.0005�

�0.0009�

�0.001�

�0.0003�

�?� Good� adhesion� to� a� variety� of�

�substrates�

�Mix� Ratio,� by� weight� -�

�Resin� :� Hardener�

�Typical� Assembly�

�Applications�

�100� :� 6�

�Electrical� modules,� Printed� circuitry,�

�Wave� guides,� Flat� cables,� High�

�frequency� shields� and� Cold� solder�

�Outgassing� Properties� :�

�Total� Mass� Loss,� %�

�Collected� Volatile� Condensable� Material,� %�

�0.64�

�0.05�

�Operating Temperature� -60� to� 110� °C�

�Application� Bonding,� Sealing� or� Repair�

�Surfaces� Ceramics,� Many� metals,� Glass� and�

�Plastic� laminates�

�TRA-DUCT� 2902� is� designed� for� electronic� bonding� and�

�sealing� applications� that� require� a� combination� of� good�

�mechanical� and� electrical� properties.�

�TRA-DUCT� 2902� passes� NASA� outgassing� standards.�

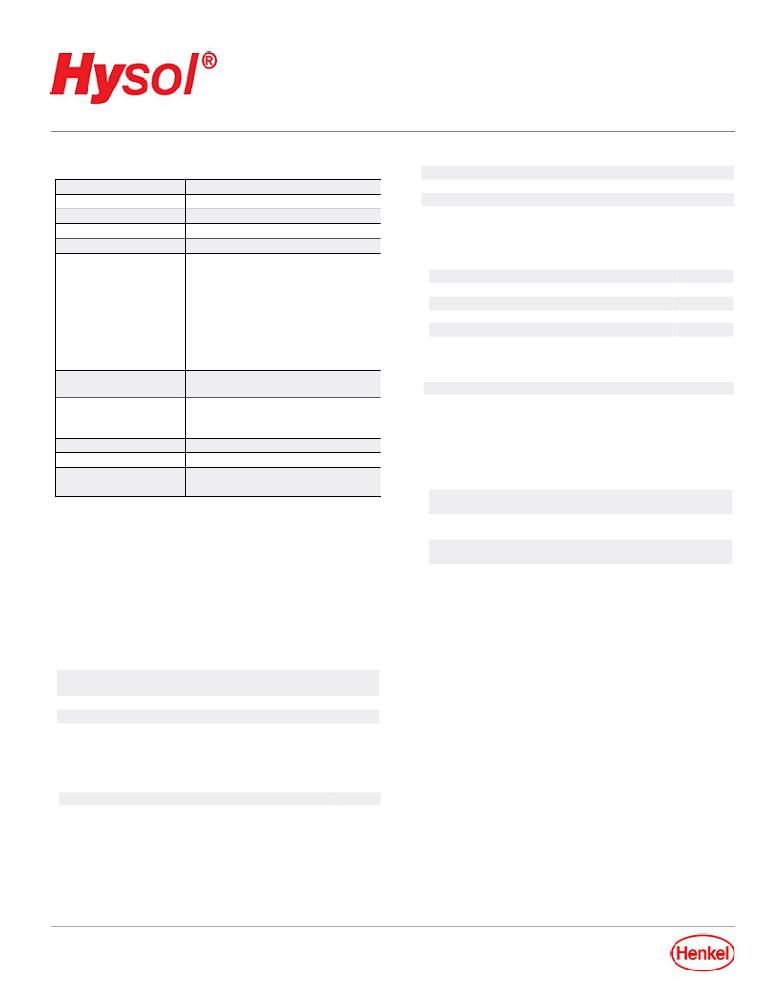

�TYPICAL� PERFORMANCE� OF� CURED� MATERIAL�

�Lap� Shear� Strength� :�

�Aluminum:�

�Cured� @� 110� °C� for� 1� hour� N/mm2�

�(psi)�

�Cured� @� 150� °C� for� 15� minutes� N/mm2�

�(psi)�

�Cured� @� 65� °C� for� 2� hours� N/mm2�

�(psi)�

�Cured� @� 25� °C� for� 24� hours� N/mm2�

�(psi)�

�11�

�(1,600)�

�11�

�(1,600)�

�7�

�(1,000)�

�5�

�(700)�

�ISO-10993-5�

�TRA-DUCT� 2902� was� tested� to� and� passed� the� requirements�

�of� ISO� 10993-5� for� Cytotoxicity.�

�TYPICAL� PROPERTIES� OF� UNCURED� MATERIAL�

�Mixed� Viscosity,� mPa·s� (cP)� :�

�GENERAL� INFORMATION�

�For� safe� handling� information� on� this� product,� consult� the�

�Material� Safety� Data� Sheet,� (MSDS).�

�cp� #52,� 10� rpm�

�Specific� Gravity,� mixed�

�20,000�

�3.2�

�Pot� life� ,� minutes�

�Flash� Point� -� See� MSDS�

�60�

�DIRECTIONS� FOR� USE�

�1.� Carefully� clean� and� dry� all� surfaces� to� be� bonded.�

�TYPICAL� CURING� PERFORMANCE�

�Cure� Schedule�

�24� hours� @� 25°C� or�

�1� to� 4� hours� @� 65°C�

�The� above� cure� profile� is� a� guideline� recommendation.� Cure�

�conditions� (time� and� temperature)� may� vary� based� on�

�customers'� experience� and� their� application� requirements,� as�

�well� as� customer� curing� equipment,� oven� loading� and� actual�

�oven� temperatures.�

�2.� Remove� clamp� and� thoroughly� mix� the� TRA-DUCT� 2902�

�epoxy� adhesive� system� components� in� the� handy� BIPAX�

�mixing-dispenser� package� until� color� is� uniform�

�throughout.�

�3.� Apply� this� completely� mixed� adhesive� to� the� prepared�

�surfaces,� and� gently� press� these� surfaces� together.�

�Contact� pressure� is� adequate� for� strong,� reliable� bonds;�

�however,� maintain� contact� until� adhesive� is� completely�

�cured.�

�相关PDF资料 |

PDF描述 |

|---|---|

| BA-F113SC | F113SC-NON CONDUCTIVE ADHESIVE |

| BA2-B2-24-610-11A-C3 | CIRCUIT BREAKER MAGNETIC 10A |

| BBRF550S | POLYSWITCH PTC .55A HOLD STRT |

| BCIM | KIT DESIGN CTLR FOR IPM MODULES |

| BDH121 | HANDLE PISTOL RED/YEL FOR SWITCH |

相关代理商/技术参数 |

参数描述 |

|---|---|

| BA2902F | 制造商:ROHM Semiconductor 功能描述:IC,OPamp,4ch,Vin=Vee to Vcc-1.5V,SOP14 |

| BA2902FC | 制造商:ROHM 制造商全称:Rohm 功能描述:Automotive Ground Sense Operational Amplifiers |

| BA2902FE2 | 制造商:ROHM 制造商全称:Rohm 功能描述:Automotive Ground Sense Operational Amplifiers |

| BA2902F-E2 | 功能描述:运算放大器 - 运放 QUAD 32V 0.7MA RoHS:否 制造商:STMicroelectronics 通道数量:4 共模抑制比(最小值):63 dB 输入补偿电压:1 mV 输入偏流(最大值):10 pA 工作电源电压:2.7 V to 5.5 V 安装风格:SMD/SMT 封装 / 箱体:QFN-16 转换速度:0.89 V/us 关闭:No 输出电流:55 mA 最大工作温度:+ 125 C 封装:Reel |

| BA2902FTR | 制造商:ROHM 制造商全称:Rohm 功能描述:Automotive Ground Sense Operational Amplifiers |

发布紧急采购,3分钟左右您将得到回复。