- 您现在的位置:买卖IC网 > PDF目录18746 > BBA-322-A (Linx Technologies Inc)MODULE RF AMP HI-GAIN BROADBAND PDF资料下载

参数资料

| 型号: | BBA-322-A |

| 厂商: | Linx Technologies Inc |

| 文件页数: | 6/7页 |

| 文件大小: | 0K |

| 描述: | MODULE RF AMP HI-GAIN BROADBAND |

| 标准包装: | 50 |

| 频率: | 0Hz ~ 3GHz |

| P1dB: | 11.2dBm(13.2mW) |

| 增益: | 20dB |

| 噪音数据: | 3.8dBm |

| RF 型: | 通用 |

| 电源电压: | 4.8 V ~ 5.2 V |

| 电流 - 电源: | 35mA ~ 60mA |

| 测试频率: | 2GHz |

| 封装/外壳: | 模块 |

| 包装: | 管件 |

�� �

�

�

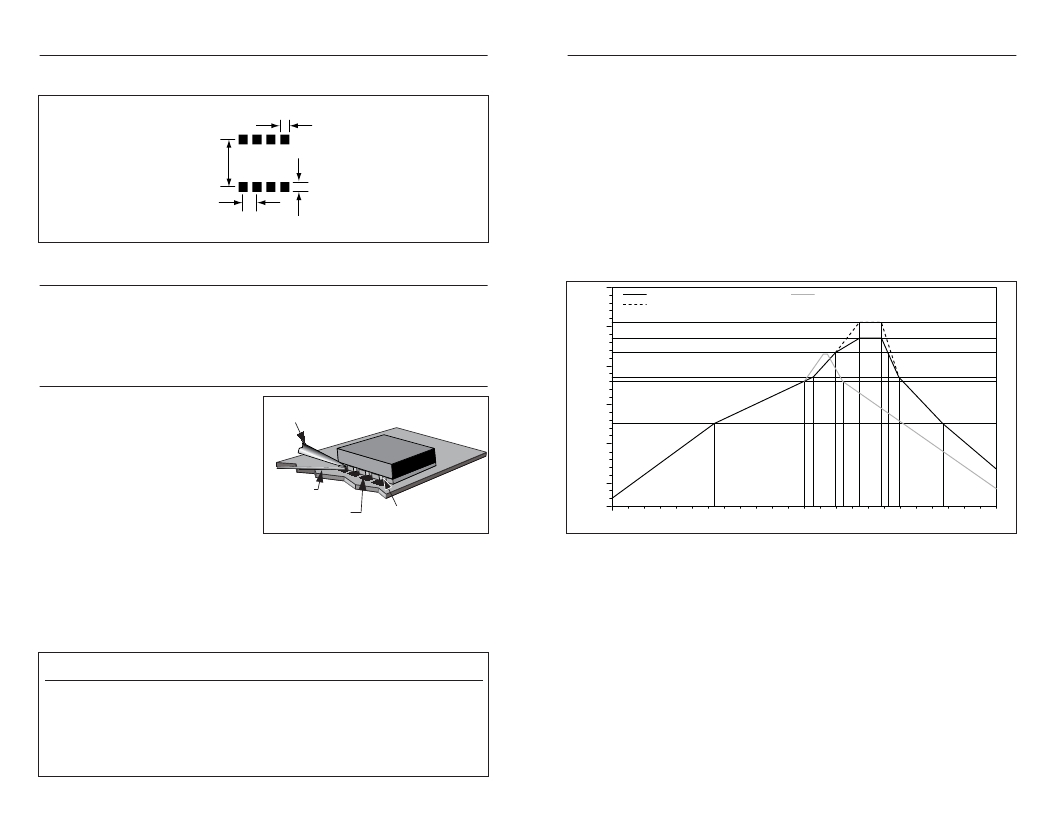

�PAD� LAYOUT�

�The� following� pad� layout� diagram� is� designed� to� facilitate� both� hand� and�

�automated� assembly.�

�0.065"�

�0.340"�

�0.070"�

�0.100"�

�Figure� 9:� Recommended� PCB� Layout�

�PRODUCTION� GUIDELINES�

�AUTOMATED� ASSEMBLY�

�For� high-volume� assembly,� most� users� will� want� to� auto-place� the� modules.� The�

�modules� have� been� designed� to� maintain� compatibility� with� reflow� processing�

�techniques;� however,� due� to� the� their� hybrid� nature,� certain� aspects� of� the�

�assembly� process� are� far� more� critical� than� for� other� component� types.�

�Following� are� brief� discussions� of� the� three� primary� areas� where� caution� must� be�

�observed.�

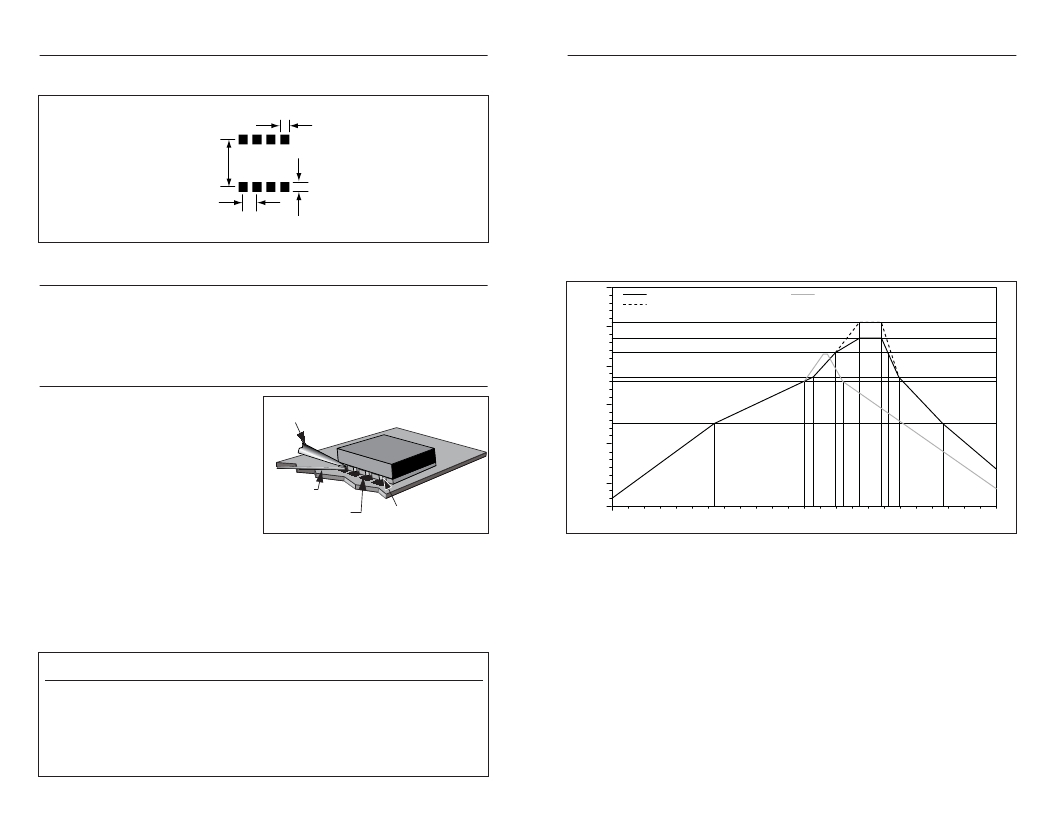

�Reflow� Temperature� Profile�

�The� single� most� critical� stage� in� the� automated� assembly� process� is� the� reflow�

�stage.� The� reflow� profile� below� should� not� be� exceeded,� since� excessive�

�temperatures� or� transport� times� during� reflow� will� irreparably� damage� the�

�modules.� Assembly� personnel� will� need� to� pay� careful� attention� to� the� oven’s�

�profile� to� ensure� that� it� meets� the� requirements� necessary� to� successfully� reflow�

�all� components� while� still� remaining� within� the� limits� mandated� by� the� modules.�

�The� figure� below� shows� the� recommended� reflow� oven� profile� for� the� modules.�

�The� modules� are� housed� in� a� hybrid� SMD� package� that� supports� hand� or�

�automated� assembly� techniques.� Since� the� modules� contain� discrete�

�components� internally,� the� assembly� procedures� are� critical� to� ensuring� the�

�reliable� function� of� the� modules.� The� following� procedures� should� be� reviewed�

�with� and� practiced� by� all� assembly� personnel.�

�HAND� ASSEMBLY�

�Pads� located� on� the� bottom� of� the�

�Soldering� Iron�

�module� are� the� primary� mounting�

�surface.� Since� these� pads� are�

�Tip�

�inaccessible� during� mounting,�

�300�

�250�

�200�

�150�

�100�

�255°C�

�235°C�

�217°C�

�185°C�

�180°C�

�125°C�

�Recommended� RoHS� Profile�

�Max� RoHS� Profile�

�Recommended� Non-RoHS� Profile�

�castellations� that� run� up� the� side� of�

�the� module� have� been� provided� to�

�facilitate� solder� wicking� to� the�

�Solder�

�50�

�module’s� underside.� This� allows� for�

�very� quick� hand� soldering� for�

�PCB� Pads�

�Castellations�

�0�

�30�

�60�

�90�

�120�

�150�

�180�

�210�

�240�

�270�

�300�

�330�

�360�

�prototyping� and� small� volume�

�Time� (� S� econd� s� )�

�production.�

�Figure� 10:� Soldering� Technique�

�Figure� 11:� Maximum� Reflow� Profile�

�If� the� recommended� pad� guidelines� have� been� followed,� the� pads� will� protrude�

�slightly� past� the� edge� of� the� module.� Use� a� fine� soldering� tip� to� heat� the� board�

�pad� and� the� castellation,� then� introduce� solder� to� the� pad� at� the� module’s� edge.�

�The� solder� will� wick� underneath� the� module,� providing� reliable� attachment.� Tack�

�one� module� corner� first� and� then� work� around� the� device,� taking� care� not� to�

�exceed� the� times� listed� below.�

�Absolute� Maximum� Solder� Times�

�Hand-Solder� Temp.� TX� +225°C� for� 10� Seconds�

�Hand-Solder� Temp.� RX� +225°C� for� 10� Seconds�

�Recommended� Solder� Melting� Point� +180°C�

�Reflow� Oven:� +220°C� Max.� (See� adjoining� diagram)�

�Page� 10�

�Shock� During� Reflow� Transport�

�Since� some� internal� module� components� may� reflow� along� with� the� components�

�placed� on� the� board� being� assembled,� it� is� imperative� that� the� modules� not� be�

�subjected� to� shock� or� vibration� during� the� time� solder� is� liquid.� Should� a� shock�

�be� applied,� some� internal� components� could� be� lifted� from� their� pads,� causing�

�the� module� to� not� function� properly.�

�Washability�

�The� modules� are� wash� resistant,� but� are� not� hermetically� sealed.� Linx�

�recommends� wash-free� manufacturing;� however,� the� modules� can� be� subjected�

�to� a� wash� cycle� provided� that� a� drying� time� is� allowed� prior� to� applying� electrical�

�power� to� the� modules.� The� drying� time� should� be� sufficient� to� allow� any� moisture�

�that� may� have� migrated� into� the� module� to� evaporate,� thus� eliminating� the�

�potential� for� shorting� damage� during� power-up� or� testing.� If� the� wash� contains�

�contaminants,� the� performance� may� be� adversely� affected,� even� after� drying.�

�Page� 11�

�相关PDF资料 |

PDF描述 |

|---|---|

| A41-80-10L | XFRMR PWR 10VCT 8A 18AWG |

| PIXIE-SO-PXSR | MODULE ZIGBEE SW ROUTER 26SMD |

| TPI A103 | BOOT HOOK FOR TPI DMM'S |

| DZ-10G-1B | SWITCH BASIC DPDT 10A 570GF |

| A41-80-12 | XFRMR PWR 12.6VCT 6.3A QC .187 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| BBA-322-A_08 | 制造商:未知厂家 制造商全称:未知厂家 功能描述:BBA SERIES RF AMPLIFIER DATA GUIDE |

| BBA3270001 | 功能描述:132.8125MHz LVPECL XO (Standard) Oscillator Surface Mount 3.3V Enable/Disable 制造商:txc corporation 系列:BB 包装:带卷(TR) 零件状态:有效 类型:XO(标准) 频率:132.8125MHz 功能:启用/禁用 输出:LVPECL 电压 - 电源:3.3V 频率稳定度:±50ppm 工作温度:-40°C ~ 85°C 电流 - 电源(最大值):- 等级:- 安装类型:表面贴装 大小/尺寸:0.276" 长 x 0.197" 宽(7.00mm x 5.00mm) 高度:0.059"(1.50mm) 封装/外壳:6-SMD,无引线(DFN,LCC) 电流 - 电源(禁用)(最大值):* 标准包装:1,000 |

| BBA3300011 | 功能描述:133.33MHz LVPECL XO (Standard) Oscillator Surface Mount 3.3V Enable/Disable 制造商:txc corporation 系列:BB 包装:带卷(TR) 零件状态:有效 类型:XO(标准) 频率:133.33MHz 功能:启用/禁用 输出:LVPECL 电压 - 电源:3.3V 频率稳定度:±50ppm 工作温度:-40°C ~ 85°C 电流 - 电源(最大值):- 等级:- 安装类型:表面贴装 大小/尺寸:0.276" 长 x 0.197" 宽(7.00mm x 5.00mm) 高度:0.059"(1.50mm) 封装/外壳:6-SMD,无引线(DFN,LCC) 电流 - 电源(禁用)(最大值):* 标准包装:1,000 |

| BBA4-63 | 制造商:Moeller Electric Corporation 功能描述:Busbar adapter 55mm 63A 1TS |

| BBA4L-63 | 制造商:Moeller Electric Corporation 功能描述:Busbar adapter 55mm 63A 2TS |

发布紧急采购,3分钟左右您将得到回复。