- 您现在的位置:买卖IC网 > PDF目录17798 > BK1005HW601-T (Taiyo Yuden)FERRITE BEAD 600 OHM 0402 PDF资料下载

参数资料

| 型号: | BK1005HW601-T |

| 厂商: | Taiyo Yuden |

| 文件页数: | 35/36页 |

| 文件大小: | 0K |

| 描述: | FERRITE BEAD 600 OHM 0402 |

| 产品培训模块: | EMC Applications |

| 产品目录绘图: | (BK,BKP)1005 Series |

| 标准包装: | 1 |

| 系列: | BK |

| 频率对应阻抗: | 600 欧姆 @ 100MHz |

| 额定电流: | 300mA |

| DC 电阻(DCR): | 最大 600 毫欧 |

| 滤波器类型: | 差模 - 单线 |

| 封装/外壳: | 0402(1005 公制) |

| 安装类型: | 表面贴装 |

| 包装: | 标准包装 |

| 高度(最大): | 0.022"(0.55mm) |

| 尺寸/尺寸: | 0.039" L x 0.020" W(1.00mm x 0.50mm) |

| 产品目录页面: | 1854 (CN2011-ZH PDF) |

| 其它名称: | 587-1851-6 |

第1页第2页第3页第4页第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页当前第35页第36页

�� �

�

�

�◆Selection� of� Flux�

�1-1.� When� too� much� halogenated� substance(Chlorine,� etc.)content� is� used� to� activate� the� flux,� or� highly� acidic� flux� is� used,� an� excessive�

�amount� of� residue� after� soldering� may� lead� to� corrosion� of� the� terminal� electrodes� or� degradation� of� insulation� resistance� on� the�

�surface� of� the� Inductor.�

�1-2.� Flux� is� used� to� increase� solderability� in� flow� soldering,� but� if� too� much� is� applied,� a� large� amount� of� flux� gas� may� be� emitted� and� may�

�detrimentally� affect� solderability.� To� minimize� the� amount� of� flux� applied,� it� is� recommended� to� use� a� flux-bubbling� system.�

�1-3.� Since� the� residue� of� water-soluble� flux� is� easily� dissolved� by� water� content� in� the� air,� the� residue� on� the� surface� of� Inductor� in� high�

�humidity� conditions� may� cause� a� degradation� of� insulation� resistance� and� therefore� affect� the� reliability� of� the� components.� The�

�cleaning� methods� and� the� capability� of� the� machines� used� should� also� be� considered� carefully� when� selecting� water-soluble� flux.�

�◆Soldering�

�1-1.� Preheating� when� soldering�

�Heating:� Chip� inductor� components� should� be� preheated� to� within� 100� to� 130℃� of� the� soldering.� Cooling:� The� temperature� difference�

�between� the� components� and� cleaning� process� should� not� be� greater� than� 100℃.�

�Chip� inductors� are� susceptible� to� thermal� shock� when� exposed� to� rapid� or� concentrated� heating� or� rapid� cooling.� Therefore,� the�

�soldering� process� must� be� conducted� with� a� great� care� so� as� to� prevent� malfunction� of� the� components� due� to� excessive� thermal�

�shock.�

�Recommended� conditions� for� soldering� Pb� free� soldering�

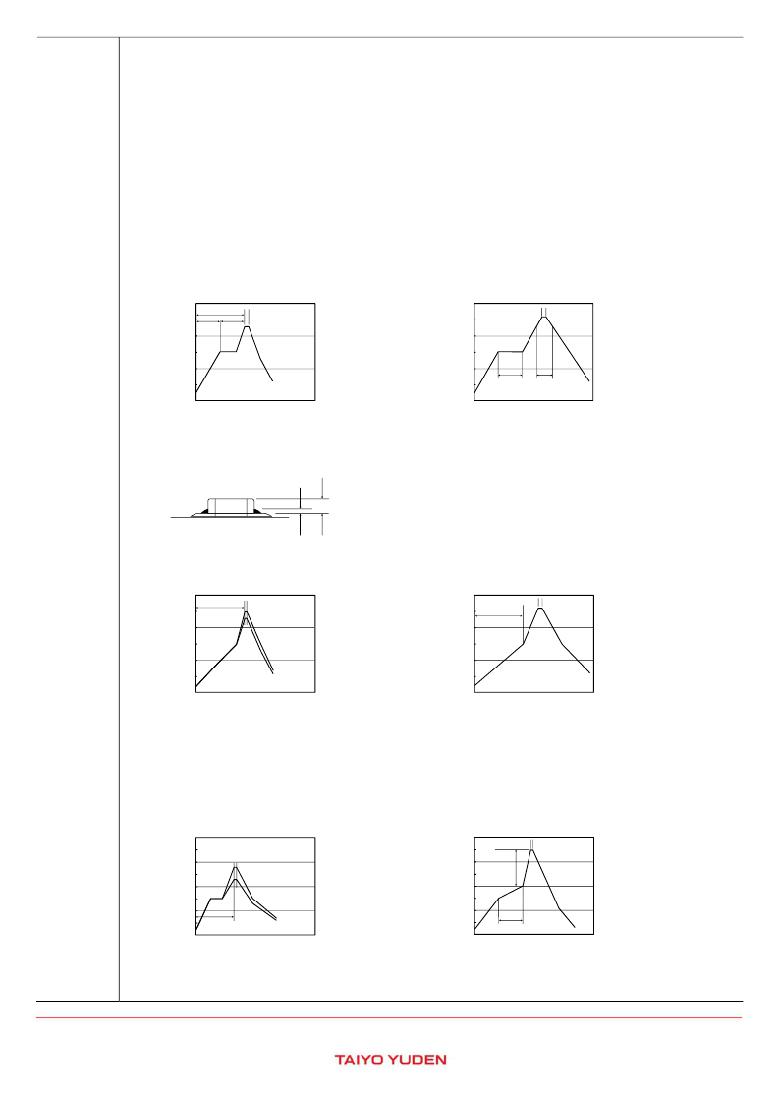

�[Reflow� soldering]�

�Temperature� profile�

�300�

�Preheating�

�60sec.� 60sec�

�230℃�

�Within� 10sec.�

�300�

�Peak�

�260℃� Max.�

�Within� 10sec.�

�200�

�Min.�

�Min.�

�Slow� cooling�

�200�

�Slow�

�cooling�

�100�

�100�

�Preheating150℃� Heating� above�

�60sec.� Min.�

�230℃�

�0�

�0�

�40sec.� Max.�

�※Ceramic� chip� components� should� be� preheated� to� within� 100� to� 130℃� of� the�

�soldering.�

�※Assured� to� be� reflow� soldering� for� 2� times.�

�Caution�

�1.� The� ideal� condition� is� to� have� solder� mass(fillet)controlled� to� 1/2� to� 1/3� of� the� thickness� of� the� inductor,� as� shown�

�below:�

�1/2T~1/3T�

�Inductor�

�Technical�

�considerations�

�Solder�

�PC� board�

�T�

�2.� Because� excessive� dwell� times� can� detrimentally� affect� solderability,� soldering� duration� should� be� kept� as� close� to�

�recommended� times� as� possible.�

�[Wave� soldering]�

�Temperature� profile�

�300�

�200�

�Preheating�

�120sec.� Min.�

�230~250℃�

�Within� 3sec.�

�300�

�200�

�120sec.� Min.�

�Peak�

�260℃� Max.�

�Within� 10sec.�

�Slow� cooling�

�Preheating�

�Slow�

�cooling�

�100�

�0�

�100�

�0�

�150℃�

�※Ceramic� chip� components� should� be� preheated� to� within� 100� to� 130℃� of� the�

�soldering.�

�※Assured� to� be� wave� soldering� for� 1� time.�

�※Except� for� reflow� soldering� type.�

�Caution�

�1.� Make� sure� the� inductors� are� preheated� sufficiently.�

�2.� The� temperature� difference� between� the� inductor� and� melted� solder� should� not� be� greater� than� 100� to� 130℃.�

�3.� Cooling� after� soldering� should� be� as� gradual� as� possible.�

�4.� Wave� soldering� must� not� be� applied� to� the� inductors� designated� as� for� reflow� soldering� only.�

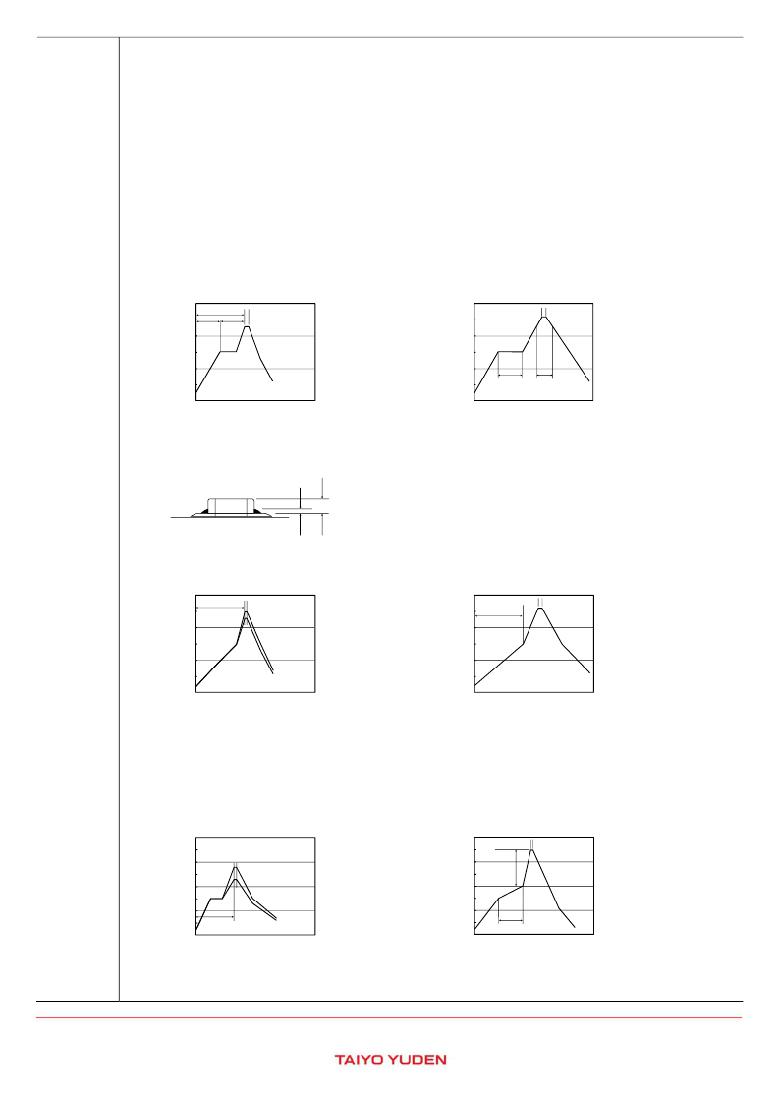

�[Hand� soldering]�

�Temperature� profile�

�400�

�300�

�230~280℃�

�Within� 3sec.�

�400�

�300�

�Peak�

�350℃� Max.�

�Within� 3sec.�

�⊿T�

�Slow� cooling�

�200�

�Slow� cooling�

�200�

�Preheating�

�100�

�Preheating�

�100�

�150℃� Min.�

�0�

�60sec.� Min.�

�0�

�60sec.� Min.�

�(※⊿T≦190℃(� 3216Type� max),� ⊿T≦130℃(� 3225� Type� min)�

�※It� is� recommended� to� use� 20W� soldering� iron� and� the� tip� is� 1φ� or� less.�

�※The� soldering� iron� should� not� directly� touch� the� components.�

�※Assured� to� be� soldering� iron� for� 1� time.�

�Note:� The� above� profiles� are� the� maximum� allowable� soldering� condition,� therefore�

�these� profiles� are� not� always� recommended.�

�?� This� catalog� contains� the� typical� specification� only� due� to� the� limitation� of� space.� When� you� consider� the� purchase� of� our� products,� please� check� our� specification.�

�For� details� of� each� product� (characteristics� graph,� reliability� information,� precautions� for� use,� and� so� on),� see� our� Web� site� (http://www.ty-top.com/)� .�

�i_mlci_prec_e-E02R01�

�相关PDF资料 |

PDF描述 |

|---|---|

| MA3216-500S4 | BEAD FERRITE 50 OHM 200MA 3216 |

| MA3216-301T4 | BEAD FERRITE 300 OHM 150MA 3216 |

| MA3216-201S4 | BEAD FERRITE 200 OHM 200MA 3216 |

| MA3216-201M4 | BEAD FERRITE 200 OHM 100MA 3216 |

| BK1608HS220-T | FERRITE BEAD 22 OHM 0603 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| BK1005HW601TK | 制造商:KEMET Corporation 功能描述:V |

| BK-1005HW601TK | 功能描述:电磁干扰滤波珠子、扼流圈和阵列 600ohms 300mA RoHS:否 制造商:AVX 阻抗: 最大直流电流:35 mA 最大直流电阻: 容差: 端接类型:SMD/SMT 电压额定值:25 V 工作温度范围:- 25 C to + 85 C 封装 / 箱体:0603 (1608 metric) |

| BK1005HW601-TV | 功能描述:600 Ohm Impedance Ferrite Bead 0402 (1005 Metric) Surface Mount 300mA 1 Lines 600 mOhm Max DCR -55°C ~ 125°C 制造商:taiyo yuden 系列:BK 包装:剪切带(CT) 零件状态:有效 滤波器类型:- 线路数:1 不同频率时的阻抗:600 欧姆 @ 100MHz 额定电流(最大):300mA 直流电阻(DCR)(最大):600 毫欧 等级:AEC-Q200 工作温度:-55°C ~ 125°C 封装/外壳:0402(1005 公制) 安装类型:表面贴装 高度(最大值):0.022"(0.55mm) 大小/尺寸:0.039" 长 x 0.020" 宽(1.00mm x 0.50mm) 标准包装:1 |

| BK1005HW680 | 制造商:TAIYO-YUDEN 制造商全称:Taiyo Yuden (U.S.A.), Inc 功能描述:MULTILAYER CHIP BEAD INDUCTORS (BK SERIES) |

| BK1005HW680T | 制造商:TAIYO YUDE 功能描述:Pb Free |

发布紧急采购,3分钟左右您将得到回复。