- 您现在的位置:买卖IC网 > PDF目录17296 > CKP2012N3R3M-T (Taiyo Yuden)INDUCTOR 3.3UH MULTILAYER 0805 PDF资料下载

参数资料

| 型号: | CKP2012N3R3M-T |

| 厂商: | Taiyo Yuden |

| 文件页数: | 28/29页 |

| 文件大小: | 0K |

| 描述: | INDUCTOR 3.3UH MULTILAYER 0805 |

| 标准包装: | 1 |

| 系列: | CK |

| 电感: | 3.3µH |

| 电流: | 700mA |

| 容差: | ±20% |

| 屏蔽: | 无屏蔽 |

| DC 电阻(DCR): | 最大 240 毫欧 |

| 封装/外壳: | 0805(2012 公制) |

| 安装类型: | 表面贴装 |

| 包装: | 标准包装 |

| 工作温度: | -40°C ~ 85°C |

| 频率 - 测试: | 1MHz |

| 其它名称: | 587-2772-6 |

第1页第2页第3页第4页第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页当前第28页第29页

�� �

�

�

�◆Selection� of� Flux�

�1-1.� When� too� much� halogenated� substance(Chlorine,� etc.)content� is� used� to� activate� the� flux,� or� highly� acidic� flux� is� used,� an� excessive�

�amount� of� residue� after� soldering� may� lead� to� corrosion� of� the� terminal� electrodes� or� degradation� of� insulation� resistance� on� the�

�surface� of� the� Inductor.�

�1-2.� Flux� is� used� to� increase� solderability� in� flow� soldering,� but� if� too� much� is� applied,� a� large� amount� of� flux� gas� may� be� emitted� and� may�

�detrimentally� affect� solderability.� To� minimize� the� amount� of� flux� applied,� it� is� recommended� to� use� a� flux-bubbling� system.�

�1-3.� Since� the� residue� of� water-soluble� flux� is� easily� dissolved� by� water� content� in� the� air,� the� residue� on� the� surface� of� Inductor� in� high�

�humidity� conditions� may� cause� a� degradation� of� insulation� resistance� and� therefore� affect� the� reliability� of� the� components.� The�

�cleaning� methods� and� the� capability� of� the� machines� used� should� also� be� considered� carefully� when� selecting� water-soluble� flux.�

�◆Soldering�

�1-1.� Preheating� when� soldering�

�Heating:� Chip� inductor� components� should� be� preheated� to� within� 100� to� 130℃� of� the� soldering.� Cooling:� The� temperature� difference�

�between� the� components� and� cleaning� process� should� not� be� greater� than� 100℃.�

�Chip� inductors� are� susceptible� to� thermal� shock� when� exposed� to� rapid� or� concentrated� heating� or� rapid� cooling.� Therefore,� the�

�soldering� process� must� be� conducted� with� a� great� care� so� as� to� prevent� malfunction� of� the� components� due� to� excessive� thermal�

�shock.�

�Recommended� conditions� for� soldering� Pb� free� soldering�

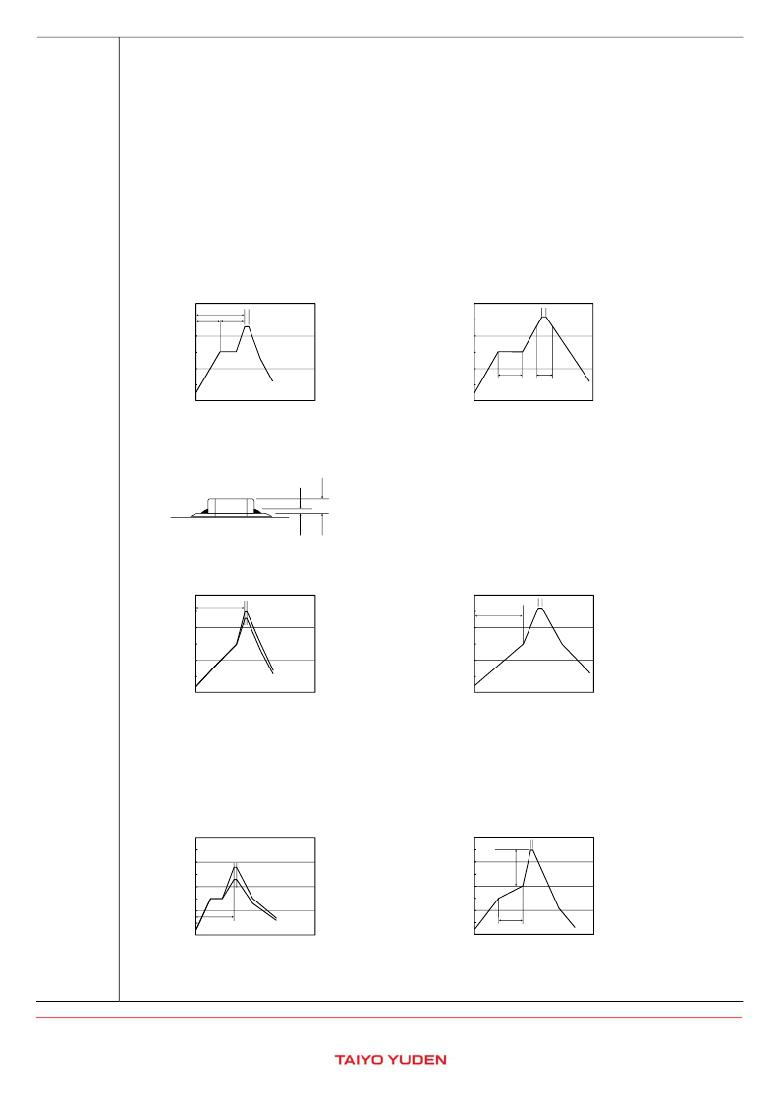

�[Reflow� soldering]�

�Temperature� profile�

�300�

�Preheating�

�60sec.� 60sec�

�230℃�

�Within� 10sec.�

�300�

�Peak�

�260℃� Max.�

�Within� 10sec.�

�200�

�Min.�

�Min.�

�Slow� cooling�

�200�

�Slow�

�cooling�

�100�

�100�

�Preheating150℃� Heating� above�

�60sec.� Min.�

�230℃�

�0�

�0�

�40sec.� Max.�

�※Ceramic� chip� components� should� be� preheated� to� within� 100� to� 130℃� of� the�

�soldering.�

�※Assured� to� be� reflow� soldering� for� 2� times.�

�Caution�

�1.� The� ideal� condition� is� to� have� solder� mass(fillet)controlled� to� 1/2� to� 1/3� of� the� thickness� of� the� inductor,� as� shown�

�below:�

�1/2T~1/3T�

�Inductor�

�Technical�

�considerations�

�Solder�

�PC� board�

�T�

�2.� Because� excessive� dwell� times� can� detrimentally� affect� solderability,� soldering� duration� should� be� kept� as� close� to�

�recommended� times� as� possible.�

�[Wave� soldering]�

�Temperature� profile�

�300�

�200�

�Preheating�

�120sec.� Min.�

�230~250℃�

�Within� 3sec.�

�300�

�200�

�120sec.� Min.�

�Peak�

�260℃� Max.�

�Within� 10sec.�

�Slow� cooling�

�Preheating�

�Slow�

�cooling�

�100�

�0�

�100�

�0�

�150℃�

�※Ceramic� chip� components� should� be� preheated� to� within� 100� to� 130℃� of� the�

�soldering.�

�※Assured� to� be� wave� soldering� for� 1� time.�

�※Except� for� reflow� soldering� type.�

�Caution�

�1.� Make� sure� the� inductors� are� preheated� sufficiently.�

�2.� The� temperature� difference� between� the� inductor� and� melted� solder� should� not� be� greater� than� 100� to� 130℃.�

�3.� Cooling� after� soldering� should� be� as� gradual� as� possible.�

�4.� Wave� soldering� must� not� be� applied� to� the� inductors� designated� as� for� reflow� soldering� only.�

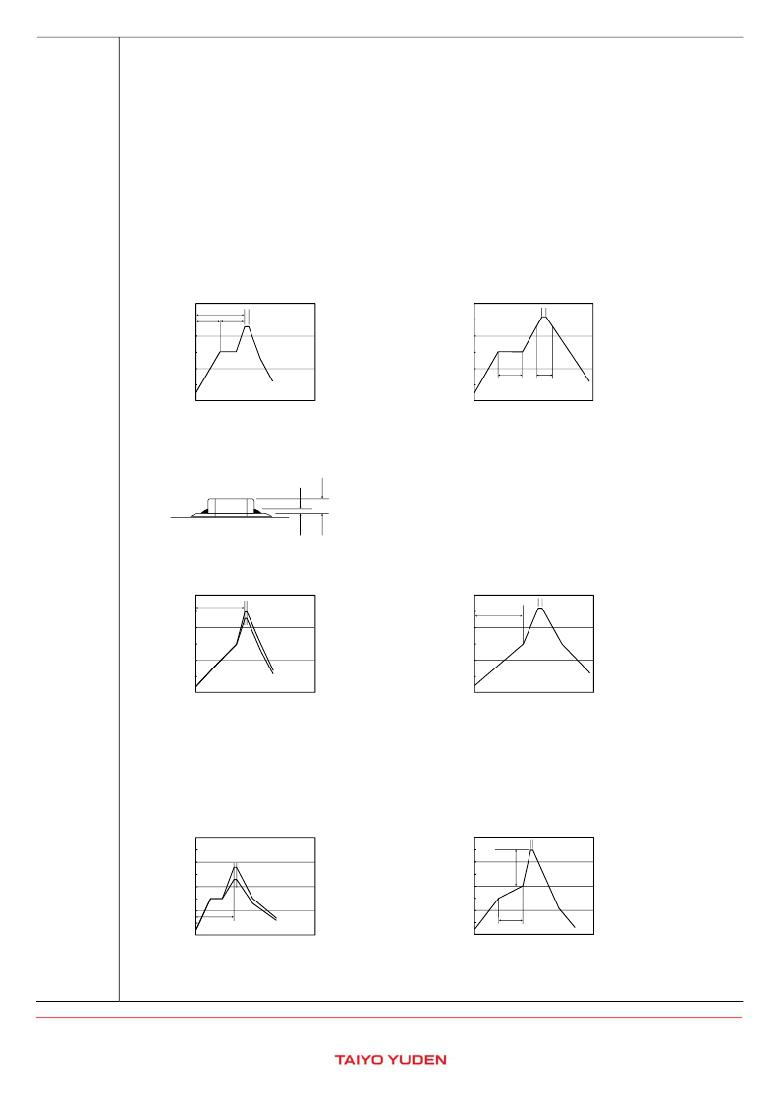

�[Hand� soldering]�

�Temperature� profile�

�400�

�300�

�230~280℃�

�Within� 3sec.�

�400�

�300�

�Peak�

�350℃� Max.�

�Within� 3sec.�

�⊿T�

�Slow� cooling�

�200�

�Slow� cooling�

�200�

�Preheating�

�100�

�Preheating�

�100�

�150℃� Min.�

�0�

�60sec.� Min.�

�0�

�60sec.� Min.�

�(※⊿T≦190℃(� 3216Type� max),� ⊿T≦130℃(� 3225� Type� min)�

�※It� is� recommended� to� use� 20W� soldering� iron� and� the� tip� is� 1φ� or� less.�

�※The� soldering� iron� should� not� directly� touch� the� components.�

�※Assured� to� be� soldering� iron� for� 1� time.�

�Note:� The� above� profiles� are� the� maximum� allowable� soldering� condition,� therefore�

�these� profiles� are� not� always� recommended.�

�?� This� catalog� contains� the� typical� specification� only� due� to� the� limitation� of� space.� When� you� consider� the� purchase� of� our� products,� please� check� our� specification.�

�For� details� of� each� product� (characteristics� graph,� reliability� information,� precautions� for� use,� and� so� on),� see� our� Web� site� (http://www.ty-top.com/)� .�

�i_mlci_prec_e-E02R01�

�相关PDF资料 |

PDF描述 |

|---|---|

| 1422311C | INDUCTOR 22UH 11A 22X14 |

| 591D227X06R3C2W20H | CAP TANT 220UF 6.3V 20% 2812 |

| LBM2016T3R3J | INDUCTOR WOUND 3.3UH 290MA 0806 |

| GMA10DRMH | CONN EDGECARD 20POS .125 SQ WW |

| 1410313C | INDUCTOR 10UH 13A 22X14 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| CKP2012N4R7M | 制造商:TAIYO YUDEN 功能描述:INDUCTOR HI CURR MULTILAYER 0805 4.7UH?20% - Tape and Reel |

| CKP2012N4R7M-T | 功能描述:固定电感器 INDCTR HICUR MLTLYR 0805 4.7uH 20% RoHS:否 制造商:AVX 电感:10 uH 容差:20 % 最大直流电流:1 A 最大直流电阻:0.075 Ohms 工作温度范围:- 40 C to + 85 C 自谐振频率:38 MHz Q 最小值:40 尺寸:4.45 mm W x 6.6 mm L x 2.92 mm H 屏蔽:Shielded 端接类型:SMD/SMT 封装 / 箱体:6.6 mm x 4.45 mm |

| CKP2012NR47M | 制造商:TAIYO YUDEN 功能描述:INDUCTOR HI CURR MULTILAYER 0805 0.47UH?20% - Tape and Reel |

| CKP2012NR47M-T | 功能描述:固定电感器 INDCTR HICUR MLTLYR 0805 0.47uH 20% RoHS:否 制造商:AVX 电感:10 uH 容差:20 % 最大直流电流:1 A 最大直流电阻:0.075 Ohms 工作温度范围:- 40 C to + 85 C 自谐振频率:38 MHz Q 最小值:40 尺寸:4.45 mm W x 6.6 mm L x 2.92 mm H 屏蔽:Shielded 端接类型:SMD/SMT 封装 / 箱体:6.6 mm x 4.45 mm |

| CKP20161R0M-T | 功能描述:固定电感器 INDCTR HICUR MLTLYR 0806 1.0uH 20% RoHS:否 制造商:AVX 电感:10 uH 容差:20 % 最大直流电流:1 A 最大直流电阻:0.075 Ohms 工作温度范围:- 40 C to + 85 C 自谐振频率:38 MHz Q 最小值:40 尺寸:4.45 mm W x 6.6 mm L x 2.92 mm H 屏蔽:Shielded 端接类型:SMD/SMT 封装 / 箱体:6.6 mm x 4.45 mm |

发布紧急采购,3分钟左右您将得到回复。