- 您现在的位置:买卖IC网 > PDF目录385382 > HIP6016CB (HARRIS SEMICONDUCTOR) Advanced PWM and Dual Linear Power Control PDF资料下载

参数资料

| 型号: | HIP6016CB |

| 厂商: | HARRIS SEMICONDUCTOR |

| 元件分类: | 稳压器 |

| 英文描述: | Advanced PWM and Dual Linear Power Control |

| 中文描述: | SWITCHING CONTROLLER, 215 kHz SWITCHING FREQ-MAX, PDSO24 |

| 文件页数: | 10/14页 |

| 文件大小: | 130K |

| 代理商: | HIP6016CB |

2-205

Shutdown

The PWM output does not switch until the soft-start voltage

(V

SS

) exceeds the oscillator’s valley voltage. Additionally, the

reference on each linear’s amplifier is clamped to the soft-

start voltage. Holding the SS pin low with an open drain or

collector signal turns off all three regulators.

The ‘11111’ VID code resulting in an INHIBIT, as shown in

Table 1, also shuts down the IC.

Layout Considerations

MOSFETs switch very fast and efficiently. The speed with

which the current transitions from one device to another

causes voltage spikes across the interconnecting impedances

and parasitic circuit elements. The voltage spikes can

degrade efficiency, radiate noise into the circuit, and lead to

device over-voltage stress. Careful component layout and

printed circuit design minimizes the voltage spikes in the

converter. Consider, as an example, the turn-off transition of

the upper PWM MOSFET. Prior to turn-off, the upper

MOSFET was carrying the full load current. During the turn-

off, current stops flowing in the upper MOSFET and is picked

up by the lower MOSFET (and/or parallel Schottky diode).

Any inductance in the switched current path generates a large

voltage spike during the switching interval. Careful component

selection, tight layout of the critical components, and short,

wide circuit traces minimize the magnitude of voltage spikes.

Contact Intersil for evaluation board drawings of the

component placement and printed circuit board.

There are two sets of critical components in a DC-DC

converter using a HIP6016 controller. The power

components are the most critical because they switch large

amounts of energy. The critical small signal components

connect to sensitive nodes or supply critical bypassing

current.

The power components should be placed first. Locate the

input capacitors close to the power switches. Minimize the

length of the connections between the input capacitors and

the power switches. Locate the output inductor and output

capacitors between the MOSFETs and the load. Locate the

PWM controller close to the MOSFETs.

The critical small signal components include the bypass

capacitor for VCC and the soft-start capacitor, C

SS

. Locate

these components close to their connecting pins on the

control IC. Minimize any leakage current paths from SS node

because the internal current source is only 11

μ

A.

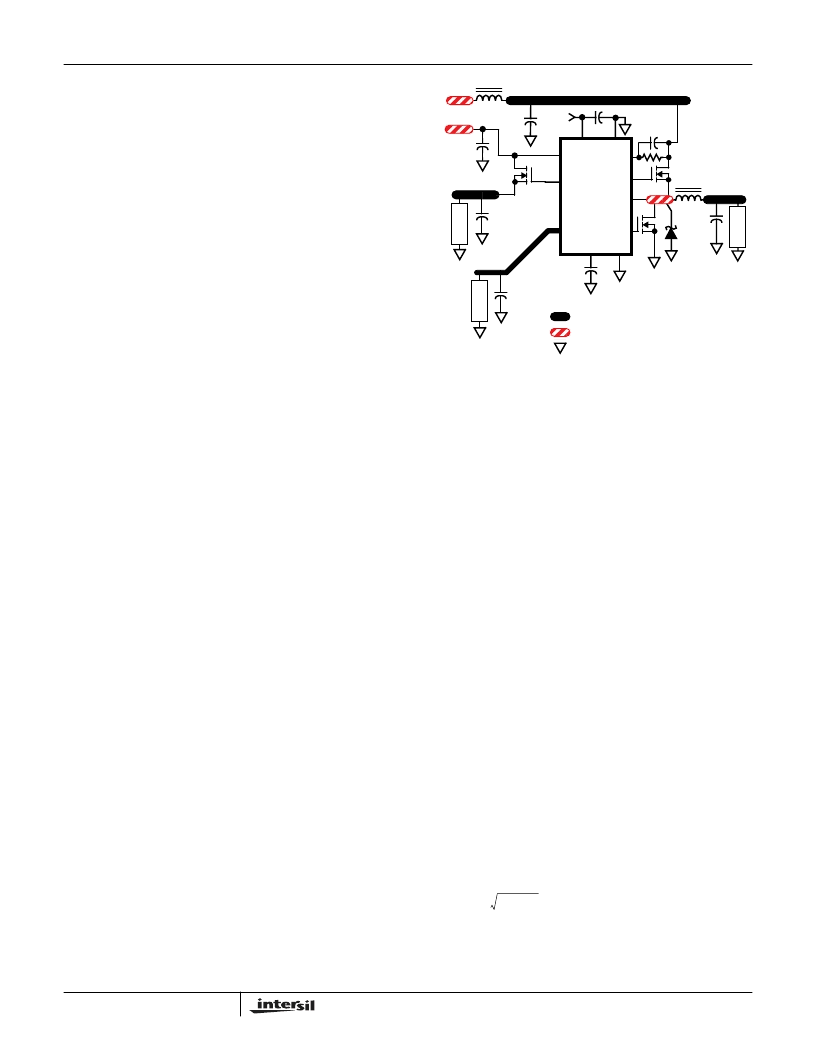

A multi-layer printed circuit board is recommended. Figure

10 shows the connections of the critical components in the

converter. Note that capacitors C

IN

and C

OUT

could each

represent numerous physical capacitors. Dedicate one solid

layer for a ground plane and make all critical component

ground connections with vias to this layer. Dedicate another

solid layer as a power plane and break this plane into

smaller islands of common voltage levels. The power plane

should support the input power and output power nodes.

Use copper filled polygons on the top and bottom circuit

layers for the phase nodes. Use the remaining printed circuit

layers for small signal wiring. The wiring traces from the

control IC to the MOSFET gate and source should be sized

to carry 1A currents. The traces for OUT2 need only be sized

for 0.2A. Locate C

OUT2

close to the HIP6016 IC.

PWM Controller Feedback Compensation

Both PWM controllers use voltage-mode control for output

regulation. This section highlights the design consideration

for a voltage-mode controller. Apply the methods and

considerations to both PWM controllers.

Figure 11 highlights the voltage-mode control loop for a

synchronous-rectified buck converter. The output voltage is

regulated to the reference voltage level. The reference

voltage level is the DAC output voltage for the PWM

controller. The error amplifier output (V

E/A

) is compared with

the oscillator (OSC) triangular wave to provide a pulse-width

modulated wave with an amplitude of V

IN

at the PHASE

node. The PWM wave is smoothed by the output filter (L

O

and C

O

).

The modulator transfer function is the small-signal transfer

function of V

OUT

/V

E/A

. This function is dominated by a DC

gain and the output filter, with a double pole break frequency

at F

LC

and a zero at F

ESR

. The DC gain of the modulator is

simply the input voltage, V

IN

, divided by the peak-to-peak

oscillator voltage,

V

OSC

.

Modulator Break Frequency Equations

The compensation network consists of the error amplifier

internal to the HIP6016 and the impedance networks Z

IN

and Z

FB

. The goal of the compensation network is to provide

FIGURE 10. PRINTED CIRCUIT BOARD POWER PLANES AND

ISLANDS

V

OUT1

Q1

Q2

C

SS

+12V

C

VCC

L

VIA CONNECTION TO GROUND PLANE

ISLAND ON POWER PLANE LAYER

ISLAND ON CIRCUIT PLANE LAYER

L

OUT1

C

OUT1

CR1

L

C

IN

V

OUT3

+5V

IN

KEY

HIP6016

SSPGND

LGATE

UGATE

PHASE

GATE3

VCC

V

IN2

GND

OCSET

+3.3V

IN

Q3

L

C

OUT2

V

OUT2

V

OUT2

R

OCSET

C

OCSET

FLC

LO

2

π

CO

×

×

-------------------1

=

FESR

π

ESR

CO

×

×

2

=

HIP6016

相关PDF资料 |

PDF描述 |

|---|---|

| HIP6017B | FPGA - 100000 SYSTEM GATE 2.5 VOLT - NOT RECOMMENDED for NEW DESIGN |

| HIP6017BCB | FPGA - 100000 SYSTEM GATE 2.5 VOLT - NOT RECOMMENDED for NEW DESIGN |

| HIP6018B | 100,000 System Gate FPGA - NOT RECOMMENDED for NEW DESIGN |

| HIP6018BCB | FPGA - 100000 SYSTEM GATE 2.5 VOLT - NOT RECOMMENDED for NEW DESIGN |

| HIP6019 | FPGA - 100000 SYSTEM GATE 2.5 VOLT - NOT RECOMMENDED for NEW DESIGN |

相关代理商/技术参数 |

参数描述 |

|---|---|

| HIP6016CB WAF | 制造商:Harris Corporation 功能描述: |

| HIP6016CB-T | 制造商:Rochester Electronics LLC 功能描述:ADVANCED PWM & CONTROL "3 IN 1"& 1.5V OUTPUTS T&R - Bulk |

| HIP6017 | 制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:Advanced PWM and Dual Linear Power Control |

| HIP6017B | 制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:Advanced PWM and Dual Linear Power Control |

| HIP6017BCB | 制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:Advanced PWM and Dual Linear Power Control |

发布紧急采购,3分钟左右您将得到回复。