- 您现在的位置:买卖IC网 > PDF目录371821 > HIP6017CB (HARRIS SEMICONDUCTOR) Advanced PWM and Dual Linear Power Control PDF资料下载

参数资料

| 型号: | HIP6017CB |

| 厂商: | HARRIS SEMICONDUCTOR |

| 元件分类: | 稳压器 |

| 英文描述: | Advanced PWM and Dual Linear Power Control |

| 中文描述: | SWITCHING CONTROLLER, 215 kHz SWITCHING FREQ-MAX, PDSO28 |

| 文件页数: | 8/14页 |

| 文件大小: | 135K |

| 代理商: | HIP6017CB |

2-217

allows V

OUT2

and V

OUT3

to slew up without generating a

fault. Cycling the bias input voltage (+12V

IN

on the VCC

pin) off then on resets the counter and the fault latch.

Over-Voltage Protection

During operation, a short on the upper PWM MOSFET (Q1)

causes V

OUT1

to increase. When the output exceeds the

over-voltage threshold of 115% (typical) of DACOUT, the

over-voltage comparator trips to set the fault latch and turns

Q2 on as required in order to regulate V

OUT1

to 1.15 x

DACOUT. This blows the input fuse and reduces V

OUT1

.

The fault latch raises the FAULT/RT pin close to VCC

potential.

A separate over-voltage circuit provides protection during

the initial application of power. For voltages on the VCC pin

below the power-on reset (and above ~4V), V

OUT1

is

monitored for voltages exceeding 1.26V. Should VSEN1

exceed this level, the lower MOSFET (Q2) is driven on as

needed to regulate V

OUT1

to 1.26V.

Over-Current Protection

All outputs are protected against excessive over-currents.

The PWM controller uses the upper MOSFET’s on-

resistance, r

DS(ON)

to monitor the current for protection

against shorted outputs. The linear regulator monitors the

current of the integrated power device and signals an over-

current condition for currents in excess of 230mA.

Additionally, both the linear regulator and the linear controller

monitor FB2 and FB3 for under-voltage to protect against

excessive currents.

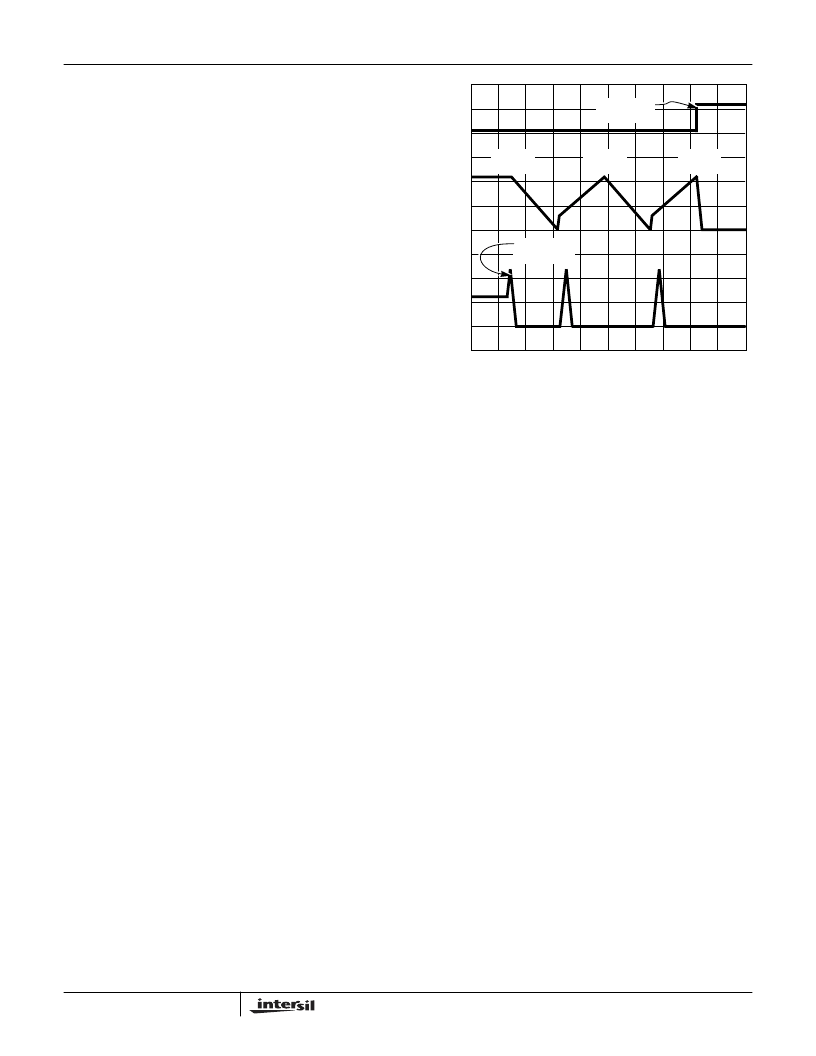

Figures 8 and 9 illustrate the over-current protection with

an overload on OUT1. The overload is applied at T0 and

the current increases through the output inductor (L

OUT1

).

At time T1, the OVER-CURRENT1 comparator trips when

the voltage across Q1 (I

D

r

DS(ON)

) exceeds the level

programmed by R

OCSET

. This inhibits all outputs,

discharges the soft-start capacitor (C

SS

) with a 11mA

current sink, and increments the counter. C

SS

recharges at

T2 and initiates a soft-start cycle with the error amplifiers

clamped by soft-start. With OUT1 still overloaded, the

inductor current increases to trip the over-current

comparator. Again, this inhibits all outputs, but the soft-start

voltage continues increasing to 4V before discharging. The

counter increments to 2. The soft-start cycle repeats at T3

and trips the over-current comparator. The SS pin voltage

increases to 4V at T4 and the counter increments to 3. This

sets the fault latch to disable the converter. The fault is

reported on the FAULT/RT pin.

The linear regulator operates in the same way as PWM1 to

over-current faults. Additionally, the linear regulator and

linear controller monitor the feedback pins for an under-

voltage. Should excessive currents cause FB2 or FB3 to fall

below the linear under-voltage threshold, the LUV signal

sets the over-current latch if C

SS

isfully charged. Blanking the

LUV signal during the C

SS

charge interval allows the linear

outputs to build above the under-voltage threshold during

normal start-up. Cycling the bias input power off then on

resets the counter and the fault latch.

Resistor R

OCSET1

programs the over-current trip level for the

PWM converter. As shown in Figure 9, the internal 200

μ

A

current sink develops a voltage across R

OCSET

(V

SET

) that is

referenced to V

IN

. The DRIVE signal enables the over-current

comparator (OVER-CURRENT1). When the voltage across

the upper MOSFET (V

DS(ON)

) exceeds V

SET

, the over-

current comparator trips to set the over-current latch. Both

V

SET

and V

DS

are referenced to V

IN

and a small capacitor

across R

OCSET

helps V

OCSET

track the variations of V

IN

due

to MOSFET switching. The over-current function will trip at a

peak inductor current (I

PEAK

) determined by:

The OC trip point varies with MOSFET’s temperature. To

avoid over-current tripping in the normal operating load

range, determine the R

OCSET

resistor from the equation

above with:

1. Themaximumr

DS(ON)

atthehighestjunctiontemperature.

2. The minimum I

OCSET

from the specification table.

3. Determine I

PEAK

for I

PEAK

> I

OUT(MAX)

+ (

I)/2, where

I is the output inductor ripple current.

S

0A

0V

2V

4V

FIGURE 8. OVER-CURRENT OPERATION

TIME

T1

T2

T3

T0

T4

F

0V

10V

COUNT

= 1

COUNT

= 2

COUNT

= 3

OVERLOAD

APPLIED

FAULT

REPORTED

I

PEAK

=

I

---------------------------------------------------

R

×

DS ON

)

HIP6017

相关PDF资料 |

PDF描述 |

|---|---|

| HIP6018EVAL1 | Advanced PWM and Dual Linear Power Control |

| HIP6018 | FPGA - 100000 SYSTEM GATE 2.5 VOLT - NOT RECOMMENDED for NEW DESIGN |

| HIP6018CB | Advanced PWM and Dual Linear Power Control |

| HIP6019BCB | Advanced Dual PWM and Dual Linear Power Control |

| HIP6019B | FPGA - 100000 SYSTEM GATE 2.5 VOLT - NOT RECOMMENDED for NEW DESIGN |

相关代理商/技术参数 |

参数描述 |

|---|---|

| HIP6017CB WAF | 制造商:Harris Corporation 功能描述: |

| HIP6017CB-T | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| HIP6017EVAL1 | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| HIP6018 | 制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:Advanced PWM and Dual Linear Power Control |

| HIP6018B | 制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:Advanced PWM and Dual Linear Power Control |

发布紧急采购,3分钟左右您将得到回复。