- 您现在的位置:买卖IC网 > PDF目录385385 > HLMP-LB17-LP0xx (Avago Technologies Ltd.) Precision Optical Performance Red, Green and Blue 4mm Standard Oval LEDs PDF资料下载

参数资料

| 型号: | HLMP-LB17-LP0xx |

| 厂商: | Avago Technologies Ltd. |

| 英文描述: | Precision Optical Performance Red, Green and Blue 4mm Standard Oval LEDs |

| 中文描述: | 精密光学性能红,绿,蓝4毫米标准椭圆形发光二极管 |

| 文件页数: | 9/12页 |

| 文件大小: | 370K |

| 代理商: | HLMP-LB17-LP0XX |

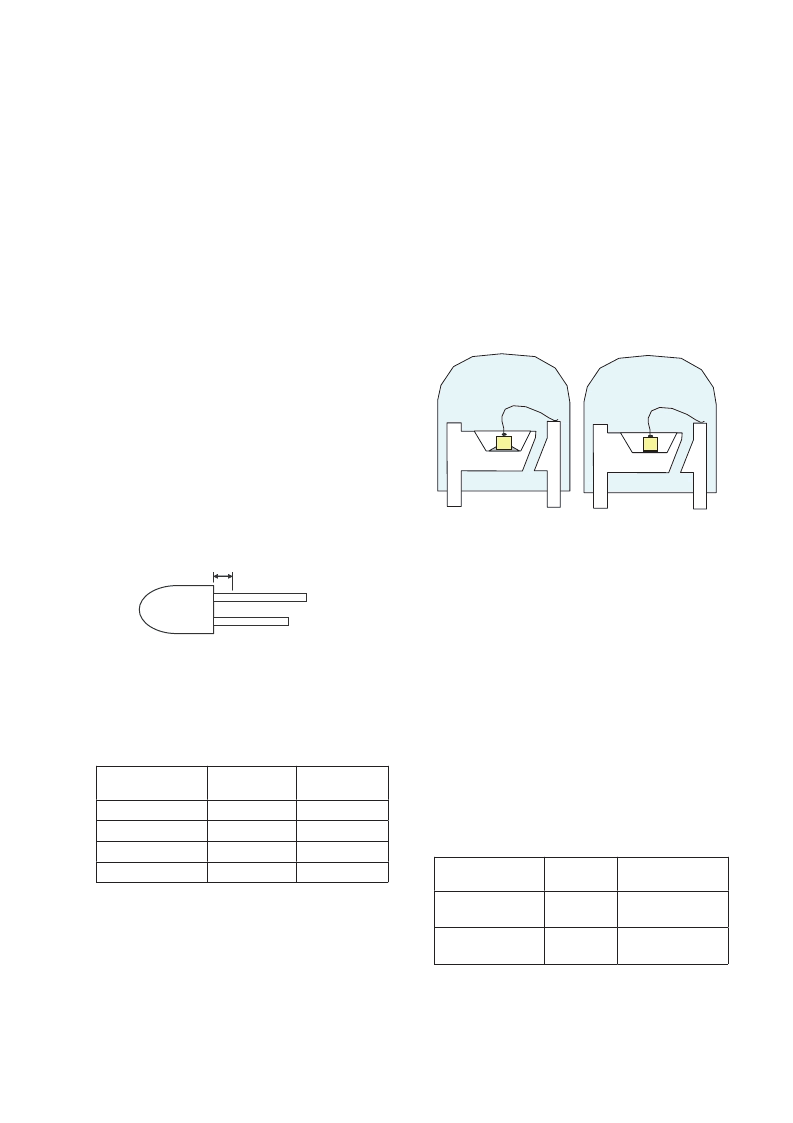

AlInGaP Device

Cathode

InGaN Device

Anode

Precautions:

Lead Forming:

The leads of an LED lamp may be preformed or cut to

length prior to insertion and soldering on PC board.

For better control, it is recommended to use proper tool

to precisely form and cut the leads to applicable length

rather than doing it manually.

If manual lead cutting is necessary, cut the leads after

the soldering process. The solder connection forms a

mechanical ground which prevents mechanical stress

due to lead cutting from traveling into LED package.

This is highly recommended for hand solder operation,

as the excess lead length also acts as small heat sink.

Soldering and Handling:

Care must be taken during PCB assembly and soldering

process to prevent damage to the LED component.

LED component may be effectively hand soldered

to PCB. However, it is only recommended under un-

avoidable circumstances such as rework. The closest

manual soldering distance of the soldering heat source

(soldering iron’s tip) to the body is 1.59mm. Soldering

the LED using soldering iron tip closer than 1.59mm

might damage the LED.

Note:

1. PCB with different size and design (component density) will have differ-

ent heat mass (heat capacity). This might cause a change in temperature

experienced by the board if same wave soldering setting is used. So,

it is recommended to re-calibrate the soldering profile again before

loading a new type of PCB.

2. Avago Technologies’ high brightness LED are using high efficiency

LED die with single wire bond as shown below. Customer is advised

to take extra precaution during wave soldering to ensure that the

maximum wave temperature does not exceed 250°C and the solder

contact time does not exceeding 3sec. Over-stressing the LED during

soldering process might cause premature failure to the LED due to

delamination.

Avago Technologies LED configuration

1.59mm

ESD precaution must be properly applied on the

soldering station and personnel to prevent ESD damage

to the LED component that is ESD sensitive. Do refer

to Avago application note AN 1142 for details. The

soldering iron used should have grounded tip to ensure

electrostatic charge is properly grounded.

Recommended soldering condition:

Wave

Soldering

[1, 2]

105 °C Max.

60 sec Max

250 °C Max.

3 sec Max.

Manual Solder

Dipping

-

-

260 °C Max.

5 sec Max

Pre-heat temperature

Preheat time

Peak temperature

Dwell time

Note:

1) Above conditions refers to measurement with thermocouple mounted

at the bottom of PCB.

2) It is recommended to use only bottom preheaters in order to reduce

thermal stress experienced by LED.

Wave soldering parameters must be set and maintained

according to the recommended temperature and dwell

time. Customer is advised to perform daily check on the

soldering profile to ensure that it is always conforming

to recommended soldering conditions.

Note: Electrical connection between bottom surface of LED die and

the lead frame is achieved through conductive paste.

Any alignment fixture that is being applied during

wave soldering should be loosely fitted and should not

apply weight or force on LED. Non metal material is

recommended as it will absorb less heat during wave

soldering process.

At elevated temperature, LED is more susceptible to

mechanical stress. Therefore, PCB must allowed to cool

down to room temperature prior to handling, which

includes removal of alignment fixture or pallet.

If PCB board contains both through hole (TH) LED and

other surface mount components, it is recommended

that surface mount components be soldered on the

top side of the PCB. If surface mount need to be on the

bottom side, these components should be soldered

using reflow soldering prior to insertion the TH LED.

Recommended PC board plated through holes (PTH)

size for LED component leads.

LED component

lead size

0.45 x 0.45 mm

(0.018x 0.018 inch)

0.50 x 0.50 mm

(0.020x 0.020 inch)

Diagonal

0.636 mm

(0.025 inch)

0.707 mm

(0.028 inch)

Plated through

hole diameter

0.98 to 1.08 mm

(0.039 to 0.043 inch)

1.05 to 1.15 mm

(0.041 to 0.045 inch)

Over-sizing the PTH can lead to twisted LED after

clinching. On the other hand under sizing the PTH can

cause difficulty inserting the TH LED.

Refer to Application Note 5334 for more information about soldering

and handling of high brightness TH LED lamps.

相关PDF资料 |

PDF描述 |

|---|---|

| HLMP-LD15 | Precision Optical Performance Red, Green and Blue 4mm Standard Oval LEDs |

| HLMP-LD15-MQTxx | Precision Optical Performance Red, Green and Blue 4mm Standard Oval LEDs |

| HLMP-LD15-NRTxx | Precision Optical Performance Red, Green and Blue 4mm Standard Oval LEDs |

| HLMP-LM17 | Precision Optical Performance Red, Green and Blue 4mm Standard Oval LEDs |

| HLMP-LM17-SV0xx | Precision Optical Performance Red, Green and Blue 4mm Standard Oval LEDs |

相关代理商/技术参数 |

参数描述 |

|---|---|

| HLMP-LB17-LP0ZZ | 功能描述:标准LED-通孔 Blue 50x100deg 50X100deg RoHS:否 制造商:Vishay Semiconductors 照明颜色:Red 光强度:0.7 mcd 波长/色温:615 nm 显示角:45 deg 透镜颜色/类型:Clear, Non-Diffused 正向电流:70 mA 正向电压:1.83 V to 3.03 V LED 大小:2 mm 系列: 封装:Tube |

| HLMP-LB61-PT0ZZ | 功能描述:标准LED-通孔 Lamp 4mm InGaN Blue 50X100deg RoHS:否 制造商:Vishay Semiconductors 照明颜色:Red 光强度:0.7 mcd 波长/色温:615 nm 显示角:45 deg 透镜颜色/类型:Clear, Non-Diffused 正向电流:70 mA 正向电压:1.83 V to 3.03 V LED 大小:2 mm 系列: 封装:Tube |

| HLMP-LB63-PT0ZZ | 功能描述:标准LED-通孔 Blue 50x100deg 50X100deg RoHS:否 制造商:Vishay Semiconductors 照明颜色:Red 光强度:0.7 mcd 波长/色温:615 nm 显示角:45 deg 透镜颜色/类型:Clear, Non-Diffused 正向电流:70 mA 正向电压:1.83 V to 3.03 V LED 大小:2 mm 系列: 封装:Tube |

| HLMP-LB63-QQ3ZZ | 制造商:Avago Technologies 功能描述: |

| HLMP-LB63-QSCZZ | 功能描述:标准LED-通孔 Blue 50x100deg RoHS:否 制造商:Vishay Semiconductors 照明颜色:Red 光强度:0.7 mcd 波长/色温:615 nm 显示角:45 deg 透镜颜色/类型:Clear, Non-Diffused 正向电流:70 mA 正向电压:1.83 V to 3.03 V LED 大小:2 mm 系列: 封装:Tube |

发布紧急采购,3分钟左右您将得到回复。