- 您现在的位置:买卖IC网 > PDF目录383107 > ILX528K (Sony Corporation) 5000 × 3 Pixel CCD Linear Sensor (Color)(5000 × 3-像素CCD线性传感器(彩色)) PDF资料下载

参数资料

| 型号: | ILX528K |

| 厂商: | Sony Corporation |

| 英文描述: | 5000 × 3 Pixel CCD Linear Sensor (Color)(5000 × 3-像素CCD线性传感器(彩色)) |

| 中文描述: | 5000 × 3像素CCD线性传感器(彩色)(5000 × 3 -像素防治荒漠化公约线性传感器(彩色)) |

| 文件页数: | 9/11页 |

| 文件大小: | 238K |

| 代理商: | ILX528K |

– 9 –

ILX528K

Notes of Handling

1) Static charge prevention

CCD image sensors are easily damaged by static discharge. Before handling be sure to take the following

protective measures.

a) Either handle bare handed or use non chargeable gloves, clothes or material. Also use conductive

shoes.

b) When handling directly use an earth band.

c) Install a conductive mat on the floor or working table to prevent the generation of static electricity.

d) Ionized air is recommended for discharge when handling CCD image sensor.

e) For the shipment of mounted substrates, use boxes treated for prevention of static charges.

2) Notes on Handling CCD Cer-DIP Packages

The following points should be observed when handling and installing cer-DIP packages.

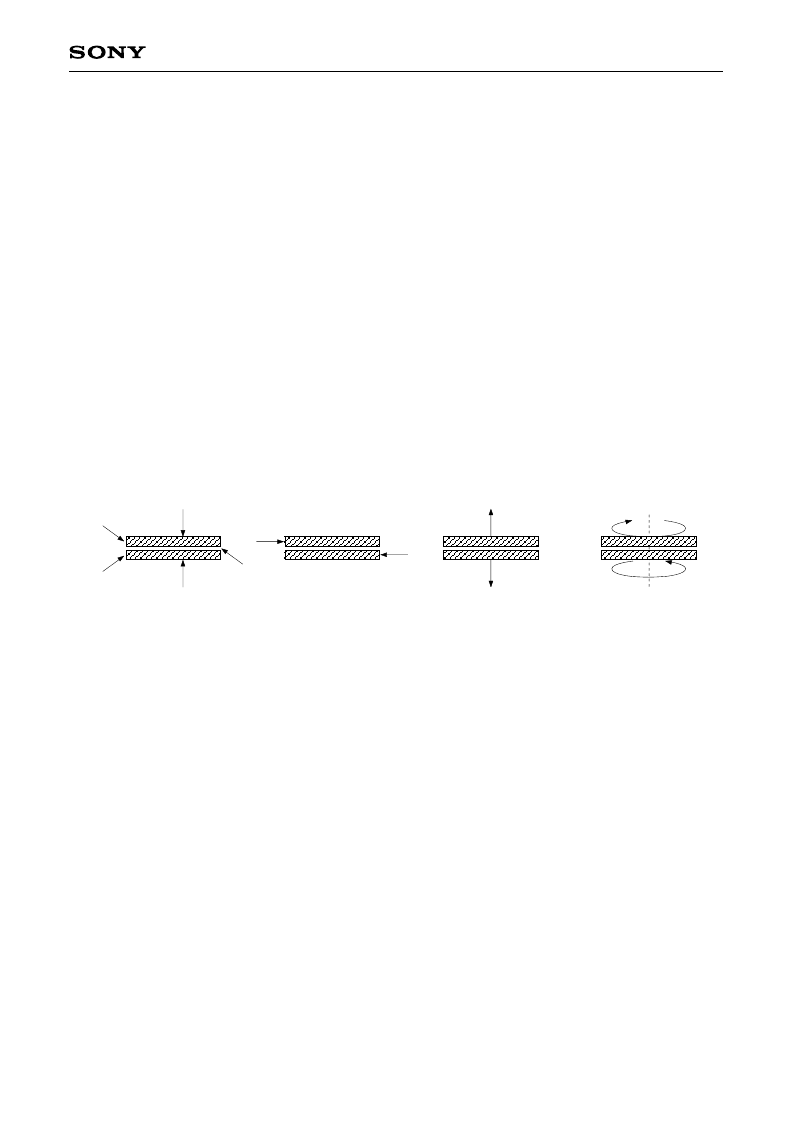

a) Remain within the following limits when applying static load to the ceramic portion of the package:

(1)Compressive strength:39N/surface (Do not apply load more than 0.7mm inside the outer perimeter of

the glass portion.)

(2)Shearing strength: 29N/surface

(3)Tensile strength: 29N/surface

(4)Torsional strength: 0.9Nm

b) In addition, if a load is applied to the entire surface by a hard component, bending stress may be

generated and the package may fracture, etc., depending on the flatness of the ceramic portion.

Therefore, for installation, either use an elastic load, such as a spring plate, or an adhesive.

c) Be aware that any of the following can cause the glass to crack: because the upper and lower ceramic

layers are shielded by low-melting glass,

(1)Applying repetitive bending stress to the external leads.

(2)Applying heat to the external leads for an extended period of time with soldering iron.

(3)Rapid cooling or heating

(4)Rapid cooling or impact to a limited portion of the low-melting glass with a small-tipped tool such as

tweezers.

(5)Prying the upper or lower ceramic layers away at a support point of the low-melting glass.

Note that the preceding notes should also be observed when removing a component from a board after it

has already been soldered.

3) Soldering

a) Make sure the package temperature does not exceed 80°C.

b) Solder dipping in a mounting furnace causes damage to the glass and other defects. Use a grounded 30W

soldering iron and solder each pin in less then 2 seconds. For repairs and remount, cool sufficiently.

c) To dismount an imaging device, do not use a solder suction equipment. When using an electric

desoldering tool, ground the controller. For the control system, use a zero cross type.

AAAA

Lower ceramic layer

AAAA

(2)

AAAA

AAAA

AAAA

AAAA

AAAA

(3)

(4)

(1)

Upper ceramic layer

相关PDF资料 |

PDF描述 |

|---|---|

| ILX531A | 5150-Pixel CCD Linear Sensor (B/W)(5150-像素CCD线性传感器(黑白)) |

| ILX532A | 7500-pixel CCD Linear Sensor (B/W) |

| ILX533 | 2700 pixel X 3 line CCD Linear Sensor (Color) |

| ILX533K | 2700 pixel X 3 line CCD Linear Sensor (Color) |

| ILX533KB | 2700 pixel X 3 line CCD Linear Sensor (Color) |

相关代理商/技术参数 |

参数描述 |

|---|---|

| ILX531A | 制造商:SONY 制造商全称:Sony Corporation 功能描述:5150-pixel CCD Linear Sensor (B/W) |

| ILX532A | 制造商:SONY 制造商全称:Sony Corporation 功能描述:7500-pixel CCD Linear Sensor (B/W) |

| ILX533 | 制造商:SONY 制造商全称:Sony Corporation 功能描述:2700 pixel X 3 line CCD Linear Sensor (Color) |

| ILX533K | 制造商:SONY 制造商全称:Sony Corporation 功能描述:2700 pixel X 3 line CCD Linear Sensor (Color) |

| ILX533KB | 制造商:SONY 制造商全称:Sony Corporation 功能描述:2700 pixel X 3 line CCD Linear Sensor (Color) |

发布紧急采购,3分钟左右您将得到回复。