- 您现在的位置:买卖IC网 > PDF目录44549 > LM2599-5.0MWC (NATIONAL SEMICONDUCTOR CORP) 7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC PDF资料下载

参数资料

| 型号: | LM2599-5.0MWC |

| 厂商: | NATIONAL SEMICONDUCTOR CORP |

| 元件分类: | 稳压器 |

| 英文描述: | 7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC |

| 封装: | WAFER |

| 文件页数: | 17/36页 |

| 文件大小: | 897K |

| 代理商: | LM2599-5.0MWC |

第1页第2页第3页第4页第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页当前第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页

Application Information (Continued)

determining a number of other circuit parameters. Param-

eters such as, peak inductor or peak switch current, mini-

mum load current before the circuit becomes discontinuous,

output ripple voltage and output capacitor ESR can all be

calculated from the peak-to-peak

I

IND. When the inductor

nomographs shown in

Figure 4 through 7 are used to select

an inductor value, the peak-to-peak inductor ripple current

can immediately be determined. The curve shown in

Figure

21 shows the range of (

I

IND) that can be expected for

different load currents. The curve also shows how the

peak-to-peak inductor ripple current (

I

IND) changes as you

go from the lower border to the upper border (for a given load

current) within an inductance region. The upper border rep-

resents a higher input voltage, while the lower border repre-

sents a lower input voltage (see Inductor Selection Guides).

These curves are only correct for continuous mode opera-

tion, and only if the inductor selection guides are used to

select the inductor value

Consider the following example:

V

OUT = 5V, maximum load current of 2.5A

V

IN = 12V, nominal, varying between 10V and 16V.

The selection guide in

Figure 5 shows that the vertical line

for a 2.5A load current, and the horizontal line for the 12V

input voltage intersect approximately midway between the

upper and lower borders of the 33 H inductance region. A

33 H inductor will allow a peak-to-peak inductor current

(

I

IND) to flow that will be a percentage of the maximum load

current. Referring to

Figure 21, follow the 2.5A line approxi-

mately midway into the inductance region, and read the

peak-to-peak inductor ripple current (

I

IND) on the left hand

axis (approximately 620 mA p-p).

As the input voltage increases to 16V, it approaches the

upper border of the inductance region, and the inductor

ripple current increases. Referring to the curve in

Figure 21,

it can be seen that for a load current of 2.5A, the

peak-to-peak inductor ripple current (

I

IND) is 620 mA with

12V in, and can range from 740 mA at the upper border (16V

in) to 500 mA at the lower border (10V in).

Once the

I

IND value is known, the following formulas can be

used to calculate additional information about the switching

regulator circuit.

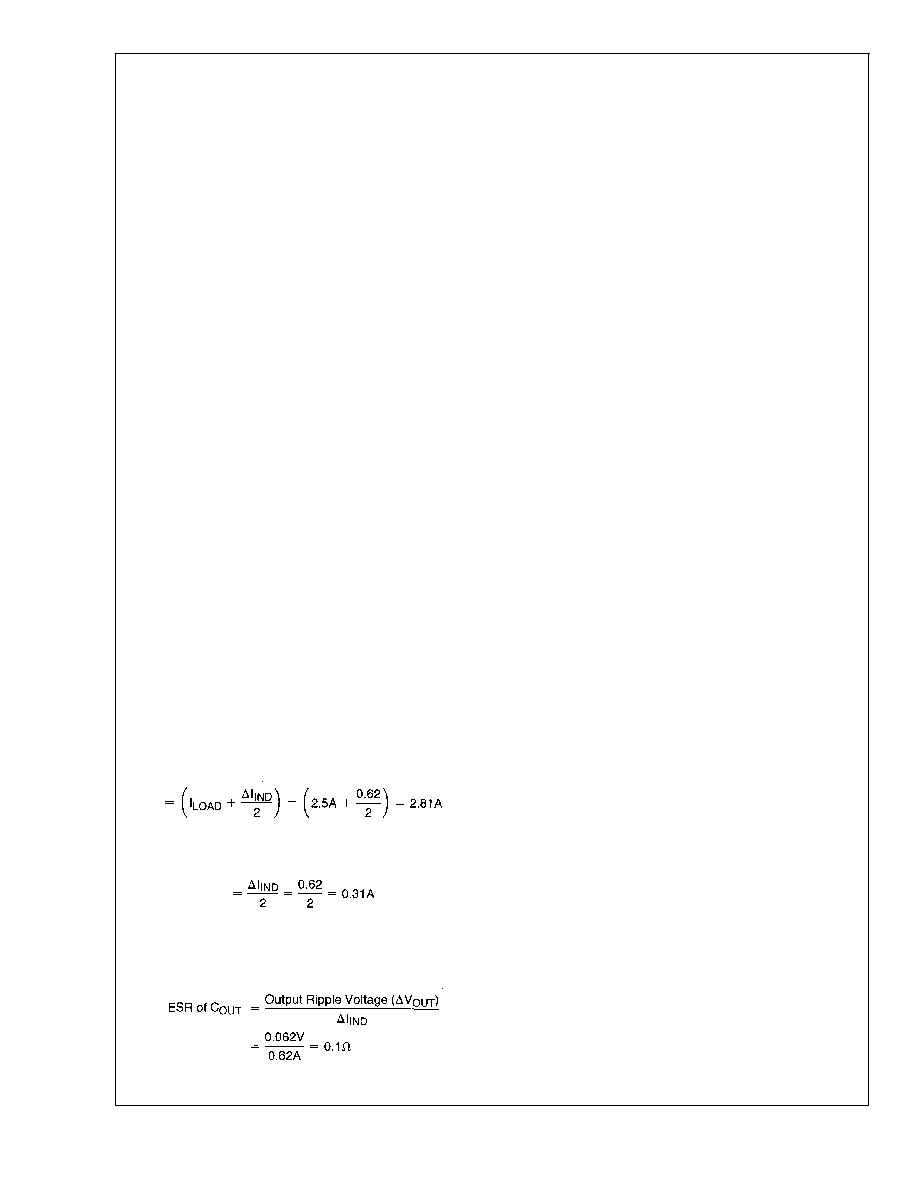

1.

Peak Inductor or peak switch current

2.

Minimum load current before the circuit becomes dis-

continuous

3.

Output Ripple Voltage = (

I

IND)x(ESR of COUT)

= 0.62Ax0.1

=62mVp-p

4.

OPEN CORE INDUCTORS

Another possible source of increased output ripple voltage or

unstable operation is from an open core inductor. Ferrite

bobbin or stick inductors have magnetic lines of flux flowing

through the air from one end of the bobbin to the other end.

These magnetic lines of flux will induce a voltage into any

wire or PC board copper trace that comes within the induc-

tor’s magnetic field. The strength of the magnetic field, the

orientation and location of the PC copper trace to the mag-

netic field, and the distance between the copper trace and

the inductor, determine the amount of voltage generated in

the copper trace. Another way of looking at this inductive

coupling is to consider the PC board copper trace as one

turn of a transformer (secondary) with the inductor winding

as the primary. Many millivolts can be generated in a copper

trace located near an open core inductor which can cause

stability problems or high output ripple voltage problems.

If unstable operation is seen, and an open core inductor is

used, it’s possible that the location of the inductor with

respect to other PC traces may be the problem. To deter-

mine if this is the problem, temporarily raise the inductor

away from the board by several inches and then check

circuit operation. If the circuit now operates correctly, then

the magnetic flux from the open core inductor is causing the

problem. Substituting a closed core inductor such as a tor-

roid or E-core will correct the problem, or re-arranging the

PC layout may be necessary. Magnetic flux cutting the IC

device ground trace, feedback trace, or the positive or nega-

tive traces of the output capacitor should be minimized.

Sometimes, locating a trace directly beneath a bobbin in-

ductor will provide good results, provided it is exactly in the

center of the inductor (because the induced voltages cancel

themselves out), but if it is off center one direction or the

other, then problems could arise. If flux problems are

present, even the direction of the inductor winding can make

a difference in some circuits.

This discussion on open core inductors is not to frighten the

user, but to alert the user on what kind of problems to watch

out for when using them. Open core bobbin or “stick” induc-

tors are an inexpensive, simple way of making a compact

efficient inductor, and they are used by the millions in many

different applications.

THERMAL CONSIDERATIONS

The LM2599 is available in two packages, a 7-pin TO-220

(T) and a 7-pin surface mount TO-263 (S).

The TO-220 package needs a heat sink under most condi-

tions. The size of the heat sink depends on the input voltage,

the output voltage, the load current and the ambient tem-

perature. The curves in

Figure 22 show the LM2599T junc-

tion temperature rises above ambient temperature for a 3A

load and different input and output voltages. The data for

these curves was taken with the LM2599T (TO-220 pack-

age) operating as a buck switching regulator in an ambient

temperature of 25C (still air). These temperature rise num-

bers are all approximate and there are many factors that can

affect these temperatures. Higher ambient temperatures re-

quire more heat sinking.

The TO-263 surface mount package tab is designed to be

soldered to the copper on a printed circuit board. The copper

and the board are the heat sink for this package and the

other heat producing components, such as the catch diode

and inductor. The pc board copper area that the package is

soldered to should be at least 0.4 in2, and ideally should

have 2 or more square inches of 2 oz. (0.0028 in) copper.

Additional copper area improves the thermal characteristics,

LM2599

www.national.com

24

相关PDF资料 |

PDF描述 |

|---|---|

| LM2599-3.3MDC | 7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC |

| LM2599-ADJMWC | 7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC |

| LM2599-3.3MWC | 7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC |

| LM2621MDC | 2.85 A SWITCHING REGULATOR, 2000 kHz SWITCHING FREQ-MAX, UUC |

| LM2622-ADJMWC | 2.3 A SWITCHING REGULATOR, 1500 kHz SWITCHING FREQ-MAX, UUC |

相关代理商/技术参数 |

参数描述 |

|---|---|

| LM2599S-12 | 功能描述:直流/直流开关转换器 RoHS:否 制造商:STMicroelectronics 最大输入电压:4.5 V 开关频率:1.5 MHz 输出电压:4.6 V 输出电流:250 mA 输出端数量:2 最大工作温度:+ 85 C 安装风格:SMD/SMT |

| LM2599S-12/NOPB | 功能描述:直流/直流开关转换器 RoHS:否 制造商:STMicroelectronics 最大输入电压:4.5 V 开关频率:1.5 MHz 输出电压:4.6 V 输出电流:250 mA 输出端数量:2 最大工作温度:+ 85 C 安装风格:SMD/SMT |

| LM2599S-3.3 | 功能描述:直流/直流开关转换器 RoHS:否 制造商:STMicroelectronics 最大输入电压:4.5 V 开关频率:1.5 MHz 输出电压:4.6 V 输出电流:250 mA 输出端数量:2 最大工作温度:+ 85 C 安装风格:SMD/SMT |

| LM2599S-3.3/NOPB | 功能描述:直流/直流开关转换器 RoHS:否 制造商:STMicroelectronics 最大输入电压:4.5 V 开关频率:1.5 MHz 输出电压:4.6 V 输出电流:250 mA 输出端数量:2 最大工作温度:+ 85 C 安装风格:SMD/SMT |

| LM2599S-5.0 | 功能描述:直流/直流开关转换器 RoHS:否 制造商:STMicroelectronics 最大输入电压:4.5 V 开关频率:1.5 MHz 输出电压:4.6 V 输出电流:250 mA 输出端数量:2 最大工作温度:+ 85 C 安装风格:SMD/SMT |

发布紧急采购,3分钟左右您将得到回复。