- 您现在的位置:买卖IC网 > PDF目录98028 > MPS2222ARLRE (ON SEMICONDUCTOR) 600 mA, 40 V, NPN, Si, SMALL SIGNAL TRANSISTOR, TO-92 PDF资料下载

参数资料

| 型号: | MPS2222ARLRE |

| 厂商: | ON SEMICONDUCTOR |

| 元件分类: | 小信号晶体管 |

| 英文描述: | 600 mA, 40 V, NPN, Si, SMALL SIGNAL TRANSISTOR, TO-92 |

| 封装: | PLASTIC, TO-226AA, 3 PIN |

| 文件页数: | 7/36页 |

| 文件大小: | 388K |

| 代理商: | MPS2222ARLRE |

第1页第2页第3页第4页第5页第6页当前第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页

7–11

Surface Mount Information

Motorola Small–Signal Transistors, FETs and Diodes Device Data

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short time could result in device failure. Therefore, the

following items should always be observed in order to mini-

mize the thermal stress to which the devices are subjected.

Always preheat the device.

The delta temperature between the preheat and soldering

should be 100

°C or less.*

When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference should be a maximum of 10

°C.

The soldering temperature and time should not exceed

260

°C for more than 10 seconds.

When shifting from preheating to soldering, the maximum

temperature gradient shall be 5

°C or less.

After soldering has been completed, the device should be

allowed to cool naturally for at least three minutes.

Gradual cooling should be used since the use of forced

cooling will increase the temperature gradient and will

result in latent failure due to mechanical stress.

Mechanical stress or shock should not be applied during

cooling.

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.

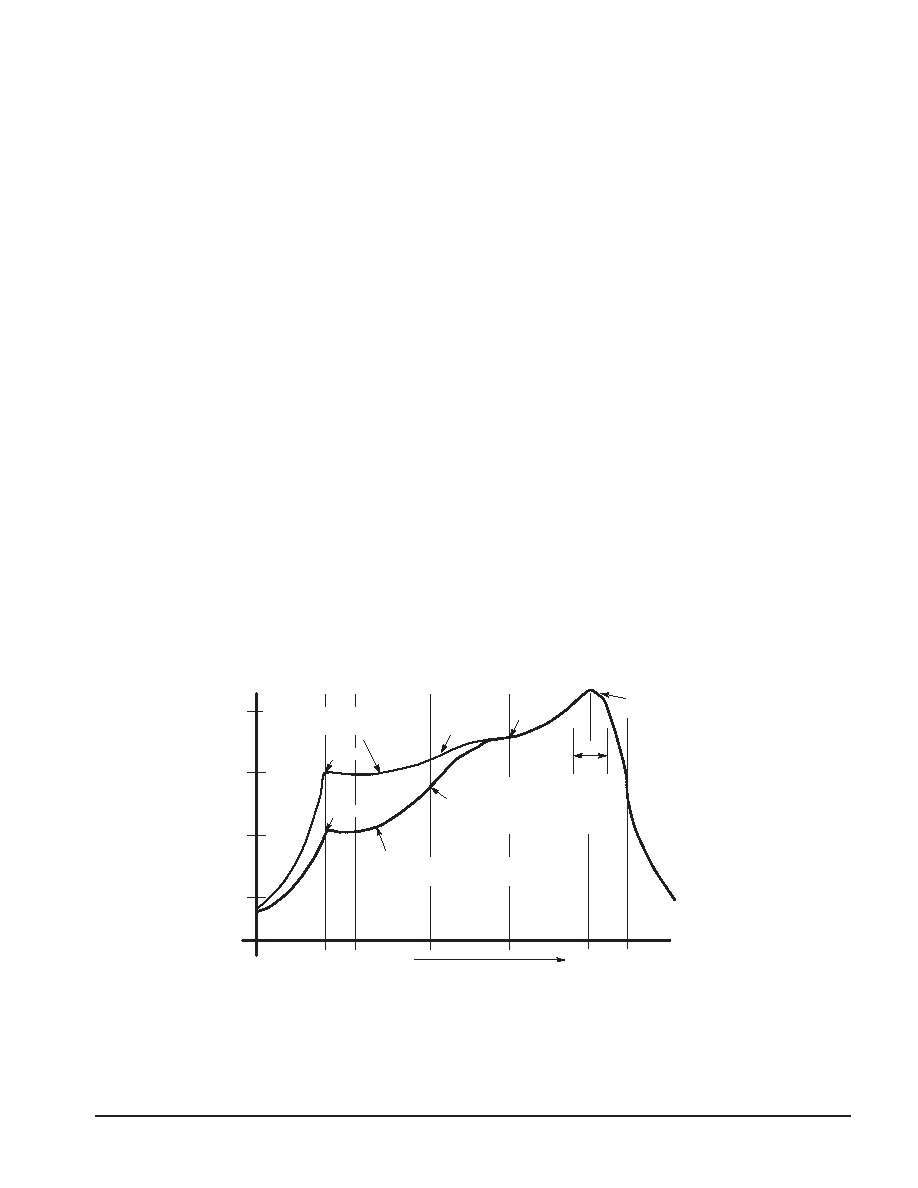

TYPICAL SOLDER HEATING PROFILE

For any given circuit board, there will be a group of control

settings that will give the desired heat pattern. The operator

must set temperatures for several heating zones and a figure

for belt speed. Taken together, these control settings make

up a heating “profile” for that particular circuit board. On

machines controlled by a computer, the computer remem-

bers these profiles from one operating session to the next.

Figure 2 shows a typical heating profile for use when

soldering a surface mount device to a printed circuit board.

This profile will vary among soldering systems, but it is a

good starting point. Factors that can affect the profile include

the type of soldering system in use, density and types of

components on the board, type of solder used, and the type

of board or substrate material being used. This profile shows

temperature versus time. The line on the graph shows the

actual temperature that might be experienced on the surface

of a test board at or near a central solder joint. The two

profiles are based on a high density and a low density board.

The Vitronics SMD310 convection/infrared reflow soldering

system was used to generate this profile. The type of solder

used was 62/36/2 Tin Lead Silver with a melting point

between 177 –189

°C. When this type of furnace is used for

solder reflow work, the circuit boards and solder joints tend to

heat first. The components on the board are then heated by

conduction. The circuit board, because it has a large surface

area, absorbs the thermal energy more efficiently, then

distributes this energy to the components. Because of this

effect, the main body of a component may be up to 30

degrees cooler than the adjacent solder joints.

STEP 1

PREHEAT

ZONE 1

“RAMP”

STEP 2

VENT

“SOAK”

STEP 3

HEATING

ZONES 2 & 5

“RAMP”

STEP 4

HEATING

ZONES 3 & 6

“SOAK”

STEP 5

HEATING

ZONES 4 & 7

“SPIKE”

STEP 6

VENT

STEP 7

COOLING

200

°C

150

°C

100

°C

50

°C

TIME (3 TO 7 MINUTES TOTAL)

TMAX

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

205

° TO 219°C

PEAK AT

SOLDER JOINT

DESIRED CURVE FOR LOW

MASS ASSEMBLIES

100

°C

150

°C

160

°C

170

°C

140

°C

Figure 2. Typical Solder Heating Profile

DESIRED CURVE FOR HIGH

MASS ASSEMBLIES

相关PDF资料 |

PDF描述 |

|---|---|

| MPS2222ARL1 | 600 mA, 40 V, NPN, Si, SMALL SIGNAL TRANSISTOR, TO-92 |

| MPS2907ARL1 | 600 mA, 60 V, PNP, Si, SMALL SIGNAL TRANSISTOR, TO-92 |

| MPS2907AZL1G | 600 mA, 60 V, PNP, Si, SMALL SIGNAL TRANSISTOR, TO-92 |

| MPS2907RL | 600 mA, 40 V, PNP, Si, SMALL SIGNAL TRANSISTOR, TO-92 |

| MPS2907RLRE | 600 mA, 40 V, PNP, Si, SMALL SIGNAL TRANSISTOR, TO-92 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| MPS2222ARLRM | 功能描述:两极晶体管 - BJT 600mA 75V NPN RoHS:否 制造商:STMicroelectronics 配置: 晶体管极性:PNP 集电极—基极电压 VCBO: 集电极—发射极最大电压 VCEO:- 40 V 发射极 - 基极电压 VEBO:- 6 V 集电极—射极饱和电压: 最大直流电集电极电流: 增益带宽产品fT: 直流集电极/Base Gain hfe Min:100 A 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PowerFLAT 2 x 2 |

| MPS2222ARLRMG | 功能描述:两极晶体管 - BJT 600mA 75V NPN RoHS:否 制造商:STMicroelectronics 配置: 晶体管极性:PNP 集电极—基极电压 VCBO: 集电极—发射极最大电压 VCEO:- 40 V 发射极 - 基极电压 VEBO:- 6 V 集电极—射极饱和电压: 最大直流电集电极电流: 增益带宽产品fT: 直流集电极/Base Gain hfe Min:100 A 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PowerFLAT 2 x 2 |

| MPS2222ARLRP | 功能描述:两极晶体管 - BJT 600mA 75V NPN RoHS:否 制造商:STMicroelectronics 配置: 晶体管极性:PNP 集电极—基极电压 VCBO: 集电极—发射极最大电压 VCEO:- 40 V 发射极 - 基极电压 VEBO:- 6 V 集电极—射极饱和电压: 最大直流电集电极电流: 增益带宽产品fT: 直流集电极/Base Gain hfe Min:100 A 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PowerFLAT 2 x 2 |

| MPS2222ARLRPG | 功能描述:两极晶体管 - BJT 600mA 75V NPN RoHS:否 制造商:STMicroelectronics 配置: 晶体管极性:PNP 集电极—基极电压 VCBO: 集电极—发射极最大电压 VCEO:- 40 V 发射极 - 基极电压 VEBO:- 6 V 集电极—射极饱和电压: 最大直流电集电极电流: 增益带宽产品fT: 直流集电极/Base Gain hfe Min:100 A 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PowerFLAT 2 x 2 |

| MPS2222AZL1 | 功能描述:两极晶体管 - BJT 600mA 75V NPN RoHS:否 制造商:STMicroelectronics 配置: 晶体管极性:PNP 集电极—基极电压 VCBO: 集电极—发射极最大电压 VCEO:- 40 V 发射极 - 基极电压 VEBO:- 6 V 集电极—射极饱和电压: 最大直流电集电极电流: 增益带宽产品fT: 直流集电极/Base Gain hfe Min:100 A 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PowerFLAT 2 x 2 |

发布紧急采购,3分钟左右您将得到回复。