- 您现在的位置:买卖IC网 > PDF目录69059 > PKU4515SIP (ERICSSON POWER MODULES AB) 1-OUTPUT 49.5 W DC-DC REG PWR SUPPLY MODULE PDF资料下载

参数资料

| 型号: | PKU4515SIP |

| 厂商: | ERICSSON POWER MODULES AB |

| 元件分类: | 电源模块 |

| 英文描述: | 1-OUTPUT 49.5 W DC-DC REG PWR SUPPLY MODULE |

| 封装: | ROHS COMPLIANT PACKAGE-8 |

| 文件页数: | 30/38页 |

| 文件大小: | 1050K |

| 代理商: | PKU4515SIP |

第1页第2页第3页第4页第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页当前第30页第31页第32页第33页第34页第35页第36页第37页第38页

Ericsson Internal

PROD. SPECIFICATION MECHANICAL

1 (4)

Prepared (also subject responsible if other)

No.

MICJAN

5/1301-BMR 602 Uen

Approved

Checked

Date

Rev

Reference

MPM/BK/E (Magnus Broman)

See §1

2007-01-31

B

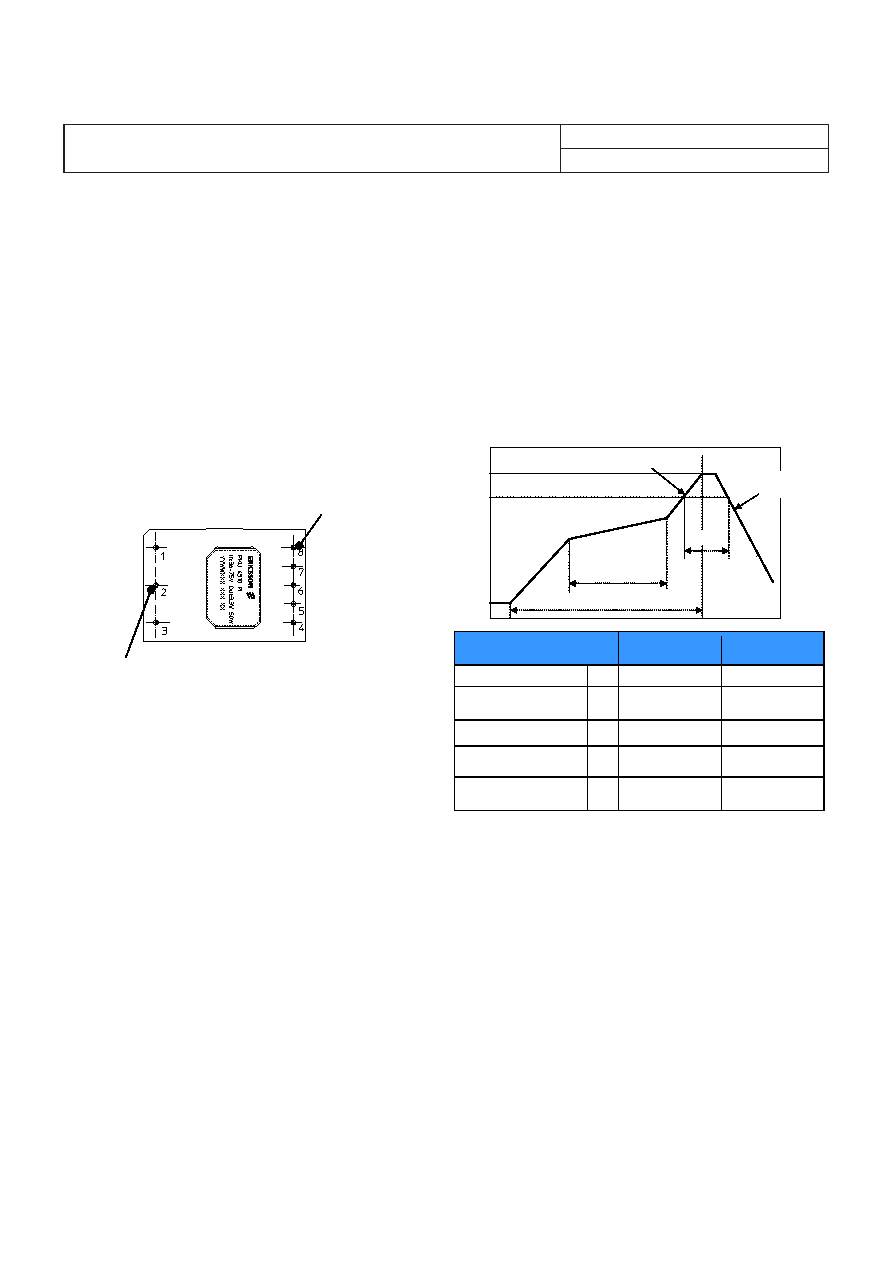

Soldering Information - Surface Mounting

The surface mount version of the product is intended for

convection or vapor phase reflow SnPb and Pb-free

processes. To achieve a good and reliable soldering result,

make sure to follow the recommendations from the solder

paste supplier, to use state-of-the-art reflow equipment and

reflow profiling techniques as well as the following guidelines.

A no-clean flux is recommended to avoid entrapment of

cleaning fluids in cavities inside the product or between the

product and the host board. The cleaning residues may affect

long time reliability and isolation voltage.

Minimum Pin Temperature Recommendations

Pin number 8 is chosen as reference location for the minimum

pin temperature recommendations since this will likely be the

coolest solder joint during the reflow process.

Pin 8 for measurement of minimum

solder joint temperature, TPIN

Pin 2 for measurement of maximum peak product

reflow temperature, TP

SnPb solder processes

For Pb solder processes, a pin temperature (T

PIN) in excess of

the solder melting temperature (T

L, +183°C for Sn63/Pb37) for

more than 30 seconds, and a peak temperature of +210°C is

recommended to ensure a reliable solder joint.

Lead-free (Pb-free) solder processes

For Pb-free solder processes, a pin temperature (T

PIN) in

excess of the solder melting temperature (T

L, +217 to +221°C

for Sn/Ag/Cu solder alloys) for more than 30 seconds, and a

peak temperature of +235°C on all solder joints is

recommended to ensure a reliable solder joint.

Peak Product Temperature Requirements

Pin number 2 is chosen as reference location for the

maximum (peak) allowed product temperature, (T

P), since this

will likely be the warmest part of the product during the reflow

process.

To avoid damage or performance degradation of the product,

the reflow profile should be optimized to avoid excessive

heating. A sufficiently extended preheat time is recommended

to ensure an even temperature across the host PCB, for both

small and large devices. To reduce the risk of excessive

heating it is also recommended to reduce the time in the

reflow zone as much as possible.

SnPb solder processes

For conventional SnPb solder processes, the product is

qualified for MSL 1 according to IPC/JEDEC standard

J-STD-020C.

During reflow, T

P must not exceed +225°C at any time.

Lead-free (Pb-free) solder processes

For Pb-free solder processes, the product is qualified for

MSL 3 according to IPC/JEDEC standard J-STD-020C.

During reflow, T

P must not exceed +260°C at any time.

25 °C

Time

Temperature

Ramp-down

(cooling)

Ramp-up

Reflow

Preheat

Time 25 °C to peak

T

P

T

L

Profile features

Sn/Pb eutectic

assembly

Pb-free assembly

Average ramp-up rate

3°C/s max

Solder melting

temperature (typical)

T

L

+183°C

+221°C

Peak product temperature T

P

+225°C

+260°C

Average ramp-down rate

6°C/s max

Time 25 °C to peak

temperature

6 minutes max

8 minutes max

Soldering Information — Through Hole Mounting

The through hole mount version of the product is intended for

manual or wave soldering. When wave soldering is used, the

temperature on the pins is specified to maximum 270°C for

maximum 10 seconds.

A maximum preheat rate of 4°C/s and temperature of max of

150°C is suggested. When soldering by hand, care should be

taken to avoid direct contact between the hot soldering iron

tip and the pins for more than a few second

s in order to prevent overheating.

A no-clean flux is recommended to avoid entrapment of

cleaning fluids in cavities inside the product or between the

product and the host board. The cleaning residues may affect

long time reliability and isolation voltage.

E

PKU 4000 PI & SI series

DC/DC converters, Input 36-75 V, Output 25 A/50 W

EN/LZT 146 308 R2B May 2007

Ericsson Power Modules AB

Technical Specication

E

PKU 4000 PI & SI series

DC/DC converters, Input 36-75 V, Output 25 A/50 W

EN/LZT 146 308 R3A May 2007

Ericsson Power Modules AB

Technical Specication

36

相关PDF资料 |

PDF描述 |

|---|---|

| PKU4318LSILA | 1-OUTPUT 30 W DC-DC REG PWR SUPPLY MODULE |

| PKU4319SILA | 1-OUTPUT 37.5 W DC-DC REG PWR SUPPLY MODULE |

| PKU4319SIPLA | 1-OUTPUT 37.5 W DC-DC REG PWR SUPPLY MODULE |

| PKU4511SIPLA | 1-OUTPUT 50 W DC-DC REG PWR SUPPLY MODULE |

| PKU4511PIPLA | 1-OUTPUT 50 W DC-DC REG PWR SUPPLY MODULE |

相关代理商/技术参数 |

参数描述 |

|---|---|

| PKU451OSI | 制造商:Ericsson 功能描述:- Trays |

| PKU4619PI | 功能描述:DC/DC转换器 63W 2.5V 25A 36-75Vin RoHS:否 制造商:Murata 产品: 输出功率: 输入电压范围:3.6 V to 5.5 V 输入电压(标称): 输出端数量:1 输出电压(通道 1):3.3 V 输出电流(通道 1):600 mA 输出电压(通道 2): 输出电流(通道 2): 安装风格:SMD/SMT 封装 / 箱体尺寸: |

| PKU4710 PI | 制造商:Ericsson 功能描述: |

| PKU4710PI | 功能描述:DC/DC转换器 66W 3.3V 20A 36-75Vin RoHS:否 制造商:Murata 产品: 输出功率: 输入电压范围:3.6 V to 5.5 V 输入电压(标称): 输出端数量:1 输出电压(通道 1):3.3 V 输出电流(通道 1):600 mA 输出电压(通道 2): 输出电流(通道 2): 安装风格:SMD/SMT 封装 / 箱体尺寸: |

| PKU50B1/8 | 制造商:TE Connectivity 功能描述: |

发布紧急采购,3分钟左右您将得到回复。