- 您现在的位置:买卖IC网 > PDF目录98225 > THS4215DGK (TEXAS INSTRUMENTS INC) 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 PDF资料下载

参数资料

| 型号: | THS4215DGK |

| 厂商: | TEXAS INSTRUMENTS INC |

| 元件分类: | 音频/视频放大 |

| 英文描述: | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| 封装: | GREEN, PLASTIC, MSOP-8 |

| 文件页数: | 21/47页 |

| 文件大小: | 1197K |

| 代理商: | THS4215DGK |

第1页第2页第3页第4页第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页当前第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页第37页第38页第39页第40页第41页第42页第43页第44页第45页第46页第47页

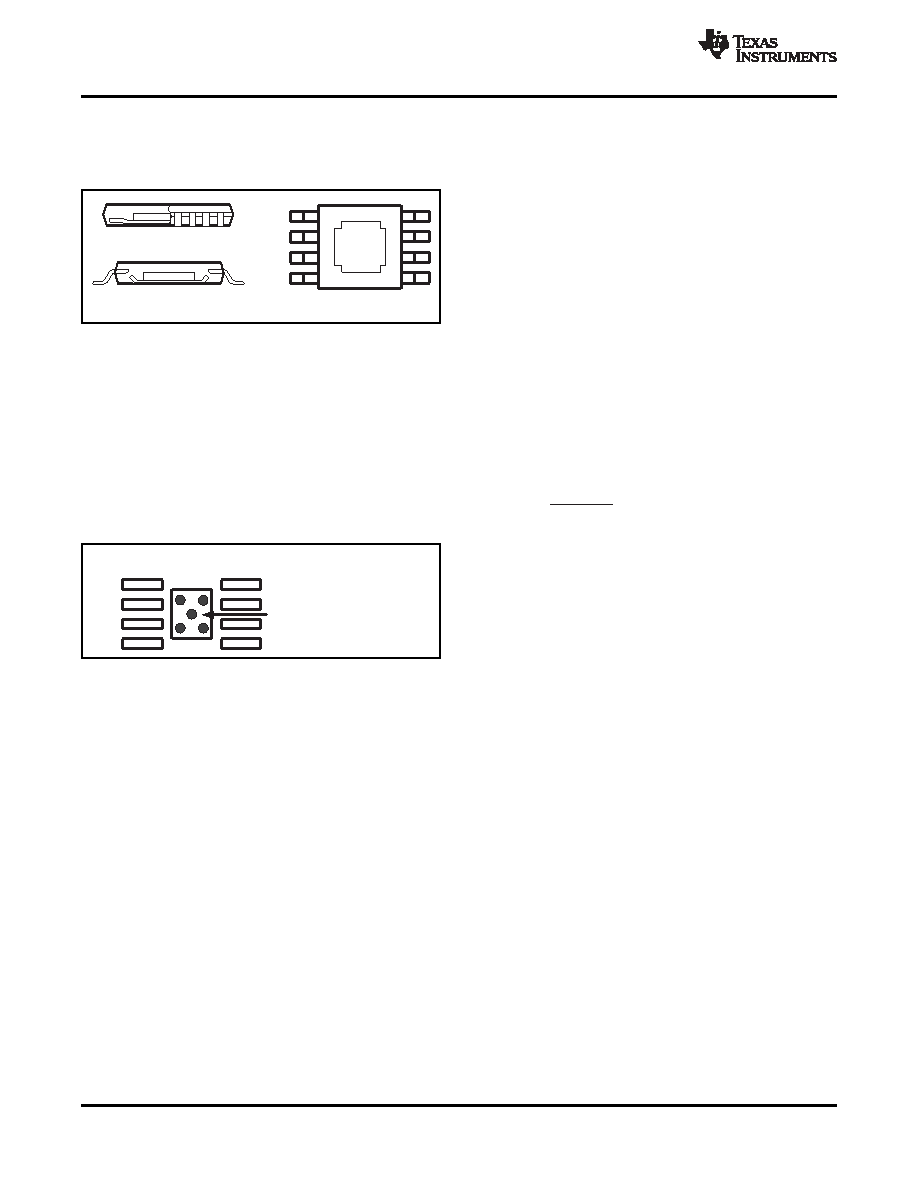

DIE

Side View (a)

DIE

End View (b)

Thermal

Pad

Bottom View (c)

P

D +

Tmax * TA

q

JA

where

PD = Maximum power dissipation of THS4211 (watts)

TMAX = Absolute maximum junction temperature (150°C)

TA = Free-ambient temperature (°C)

θJA = θJC + θCA

θJC = Thermal coefficient from junction to the case

θCA = Thermal coefficient from the case to ambient air

(

°C/W).

Single or Dual

68 Mils x 70 Mils

(Via Diameter = 13 Mils)

SLOS400E – SEPTEMBER 2002 – REVISED SEPTEMBER 2009 ................................................................................................................................... www.ti.com

The PowerPAD package represents a breakthrough

transfer. Therefore, the holes under the THS4211

in combining the small area and ease of assembly of

and THS4215 PowerPAD package should make

surface

mount

with

the

heretofore

awkward

their connection to the internal ground plane, with

mechanical methods of heatsinking.

a

complete

connection

around

the

entire

circumference of the plated-through hole.

6. The top-side solder mask should leave the

terminals of the package and the thermal pad

area with its five holes exposed. The bottom-side

solder mask should cover the five holes of the

thermal pad area. This prevents solder from

being pulled away from the thermal pad area

during the reflow process.

7. Apply solder paste to the exposed thermal pad

Figure 89. Views of Thermally

area and all of the IC terminals.

Enhanced Package

8. With these preparatory steps in place, the IC is

simply placed in position and run through the

Although there are many ways to properly heatsink

solder

reflow

operation

as

any

standard

the PowerPAD package, the following steps illustrate

surface-mount component. This results in a part

the recommended approach.

that is properly installed.

For a given

θJA, the maximum power dissipation is

PowerPAD PCB LAYOUT CONSIDERATIONS

shown in Figure 91 and is calculated by Equation 6:

1. Prepare the PCB with a top side etch pattern as

shown in Figure 90. There should be etching for

the leads as well as etch for the thermal pad.

(6)

The next consideration is the package constraints.

Figure 90. PowerPAD PCB Etch and

The two sources of heat within an amplifier are

Via Pattern

quiescent power and output power. The designer

should

never

forget

about

the

quiescent

heat

2. Place five holes in the area of the thermal pad.

generated within the device, especially multi-amplifier

These holes should be 13 mils in diameter. Keep

devices. Because these devices have linear output

them small so that solder wicking through the

stages (Class AB), most of the heat dissipation is at

holes is not a problem during reflow.

low output voltages with high output currents.

3. Additional vias may be placed anywhere along

The other key factor when dealing with power

the thermal plane outside of the thermal pad

dissipation is how the devices are mounted on the

area. They help dissipate the heat generated by

PCB. The PowerPAD devices are extremely useful

the THS4211 and THS4215 IC. These additional

for heat dissipation. But, the device should always be

vias may be larger than the 13-mil diameter vias

soldered to a copper plane to fully use the heat

directly under the thermal pad. They can be

dissipation properties of the PowerPAD. The SOIC

larger because they are not in the thermal pad

package, on the other hand, is highly dependent on

area to be soldered, so wicking is not a problem.

how it is mounted on the PCB. As more trace and

4. Connect all holes to the internal ground plane.

copper area is placed around the device,

θJA

5. When connecting these holes to the ground

decreases

and

the

heat

dissipation

capability

plane, do not use the typical web or spoke via

increases. For a single package, the sum of the RMS

connection methodology. Web connections have

output currents and voltages should be used to

a high thermal resistance connection that is

choose the proper package.

useful for slowing the heat transfer during

soldering operations. This resistance makes the

soldering of vias that have plane connections

easier. In this application, however, low thermal

resistance is desired for the most efficient heat

28

Copyright 2002–2009, Texas Instruments Incorporated

相关PDF资料 |

PDF描述 |

|---|---|

| THS4215DGKRG4 | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS4215DGNG4 | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS4215DRG4 | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS4215DRBRG4 | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

| THS4215DGKG4 | 1 CHANNEL, VIDEO AMPLIFIER, PDSO8 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| THS4215DGKG4 | 功能描述:高速运算放大器 Super-Fast Ultr-Lo- Distortion Hi-Speed RoHS:否 制造商:Texas Instruments 通道数量:1 电压增益 dB:116 dB 输入补偿电压:0.5 mV 转换速度:55 V/us 工作电源电压:36 V 电源电流:7.5 mA 最大工作温度:+ 85 C 安装风格:SMD/SMT 封装 / 箱体:SOIC-8 封装:Tube |

| THS4215DGKR | 功能描述:高速运算放大器 Super-Fast Ultr-Lo- Distortion Hi-Speed RoHS:否 制造商:Texas Instruments 通道数量:1 电压增益 dB:116 dB 输入补偿电压:0.5 mV 转换速度:55 V/us 工作电源电压:36 V 电源电流:7.5 mA 最大工作温度:+ 85 C 安装风格:SMD/SMT 封装 / 箱体:SOIC-8 封装:Tube |

| THS4215DGKRG4 | 功能描述:高速运算放大器 Super-Fast Ultr-Lo- Distortion Hi-Speed RoHS:否 制造商:Texas Instruments 通道数量:1 电压增益 dB:116 dB 输入补偿电压:0.5 mV 转换速度:55 V/us 工作电源电压:36 V 电源电流:7.5 mA 最大工作温度:+ 85 C 安装风格:SMD/SMT 封装 / 箱体:SOIC-8 封装:Tube |

| THS4215DGN | 功能描述:高速运算放大器 Super-Fast Ultr-Lo- Distortion Hi-Speed RoHS:否 制造商:Texas Instruments 通道数量:1 电压增益 dB:116 dB 输入补偿电压:0.5 mV 转换速度:55 V/us 工作电源电压:36 V 电源电流:7.5 mA 最大工作温度:+ 85 C 安装风格:SMD/SMT 封装 / 箱体:SOIC-8 封装:Tube |

| THS4215DGNG4 | 功能描述:高速运算放大器 Super-Fast Ultr-Lo- Distortion Hi-Speed RoHS:否 制造商:Texas Instruments 通道数量:1 电压增益 dB:116 dB 输入补偿电压:0.5 mV 转换速度:55 V/us 工作电源电压:36 V 电源电流:7.5 mA 最大工作温度:+ 85 C 安装风格:SMD/SMT 封装 / 箱体:SOIC-8 封装:Tube |

发布紧急采购,3分钟左右您将得到回复。