- 您现在的位置:买卖IC网 > PDF目录18266 > TK-70INS (OK Industries/Div of Jonard Ind Corp)TOOL KIT INSULATED SCREWDRIVER PDF资料下载

参数资料

| 型号: | TK-70INS |

| 厂商: | OK Industries/Div of Jonard Ind Corp |

| 文件页数: | 4/52页 |

| 文件大小: | 0K |

| 描述: | TOOL KIT INSULATED SCREWDRIVER |

| 标准包装: | 1 |

| 类型: | 螺丝刀组 |

| 特点: | 1000V 绝缘 |

| 所含物品: | 3 十字槽,4 一字槽(平头) |

| 其它名称: | K542 |

第1页第2页第3页当前第4页第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页第37页第38页第39页第40页第41页第42页第43页第44页第45页第46页第47页第48页第49页第50页第51页第52页

�� �

�

�

�W� I� R� E� W� R� A� P� P� I� N� G� O� V� E� RV� I� E� W�

�Wire� Wrapping� is� a� method� of� making� a� wire� connection� by� coiling� the� bare� wire� around� the� sharp� corners� of� a�

�terminal� under� mechanical� tension.� The� technology� was� developed� as� an� alternative� to� soldering,� which� presents�

�various� safety� and� reliability� problems� in� many� applications.� A� principal� advantage� of� wire� wrapping� is� that� it�

�provides� a� high-reliability� connection� that� is� also� easily� removed� to� correct� or� modify� a� wiring� layout.� Wire� wrapping�

�subjects� the� wire� to� tremendous� tension� and� compression� forces,� causing� the� oxide� layer� on� both� wire� and� terminal�

�to� be� crushed� or� sheared,� resulting� in� a� clean,� oxide-free� metal-to-metal� contact.� A� standard� wrap� is� generally� used�

�for� 24� AWG� and� larger� diameter� wires;� a� modified� wrap� is� typically� used� for� 26� AWG� and� smaller� wires,� and� is� used�

�almost� exclusively� for� 28� to� 30� AWG� wires.� In� either� case,� the� wrap� style� affects� only� the� connection’s� mechanical�

�stability;� both� styles� provide� suitable� electrical� connections.�

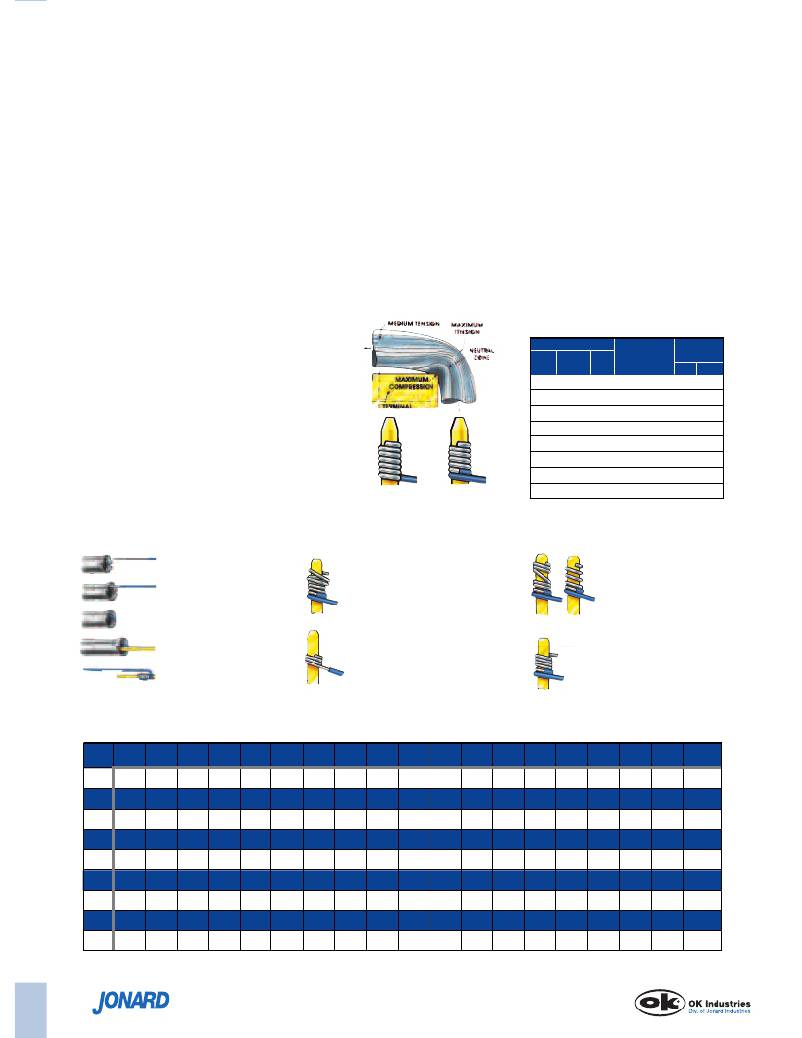

�METAL� -� TO� -� METAL� CONTACT�

�By� bending� the� wire� around� the� sharp� corner�

�of� the� terminal,� the� oxide� layer� on� both� wire�

�and� terminal� is� crushed� or� sheared,� and� a� clean,�

�STRIP� FORCE� CHART*�

�Wire� Size� Min.� number� Min.� strip�

�AWG� Dia.� Dia.� of� turns� force�

�inches� mm� (Bare� Wire)� lbs.� gms�

�oxide-free� metal-to-metal� contact� is� obtained.�

�A�

�16� .051� 1.30� 4�

�18� .0403� 1.00� 4�

�15� 6800�

�15� 6800�

�TYPES�

�OF�

�WRAP�

�B�

�20� .032� 0.80� 5�

�22� .0253� 0.65� 5�

�8� 3600�

�8� 3600�

�A� “Regular”� bit� wraps� the� bare� wire� around� the� terminal.�

�24� .0201� 0.50� 6�

�7� 3200�

�A� “Modified”� bit� wraps� a� portion� of� insulation� around�

�the� terminal� in� addition� to� the� bare� wire.This�

�greatly� increases� the� ability� to� withstand� vibration.�

�HOW�

�TO� MAKE� WIRE�

�Regular�

�Modified�

�26� .0159� 0.40� 7�

�28� .0126� 0.32� 7�

�30� .0100� 0.25� 7�

�*Conforms� to� MIL-STD-1130B�

�6� 2700�

�5� 2200�

�3.3� 1500�

�WRAPPED� CONNECTIONS�

�SOME� HINTS� ON� MAKING� WRAPPED� CONNECTIONS�

�Step� 1:� Bit,� Sleeve� and�

�Pre-Stripped� Wire�

�Step� 2:� Wire� Insertion�

�Step� 3:� Wire� Anchoring�

�Step� 4:� Terminal�

�Insertion�

�Step� 5:� Finished�

�Connection�

�OVERWRAP�

�Do� not� press� too� hard.� Let� the� OK�

�tools� do� the� work.� Excessive�

�pressure� can� lead� to� overwrapping.�

�Backforce� "BF"� to� prevent�

�overwrapping� is� available� on� most�

�power� tools� and� is� recommended�

�for� use� with� 26� through� 30� AWG�

�wire.�

�INSUFFICIENT� TURNS�

�It’s� easy� to� feed� wire� into� the� slot� in�

�the� OK� bit� correctly.� Be� sure� the�

�stripped� end� of� the� wire� is� “pushed-�

�in”� all� the� way.�

�OPEN� WRAP� &� SPIRAL�

�WRAP�

�Just� keep� the� OK� tool� on� the�

�terminal� until� the� wrap� is�

�complete.� Early� removal� can�

�result� in� spiral� and� open�

�wraps.�

�PIGTAIL�

�Wire� wrapping� is� a� precision�

�technique� and� the� wrong� bit� and�

�sleeve� just� cannot� do� the� job.�

�Improper� selection� can� cause�

�problems� ranging� from� “Pigtails”�

�to� loose� wraps.�

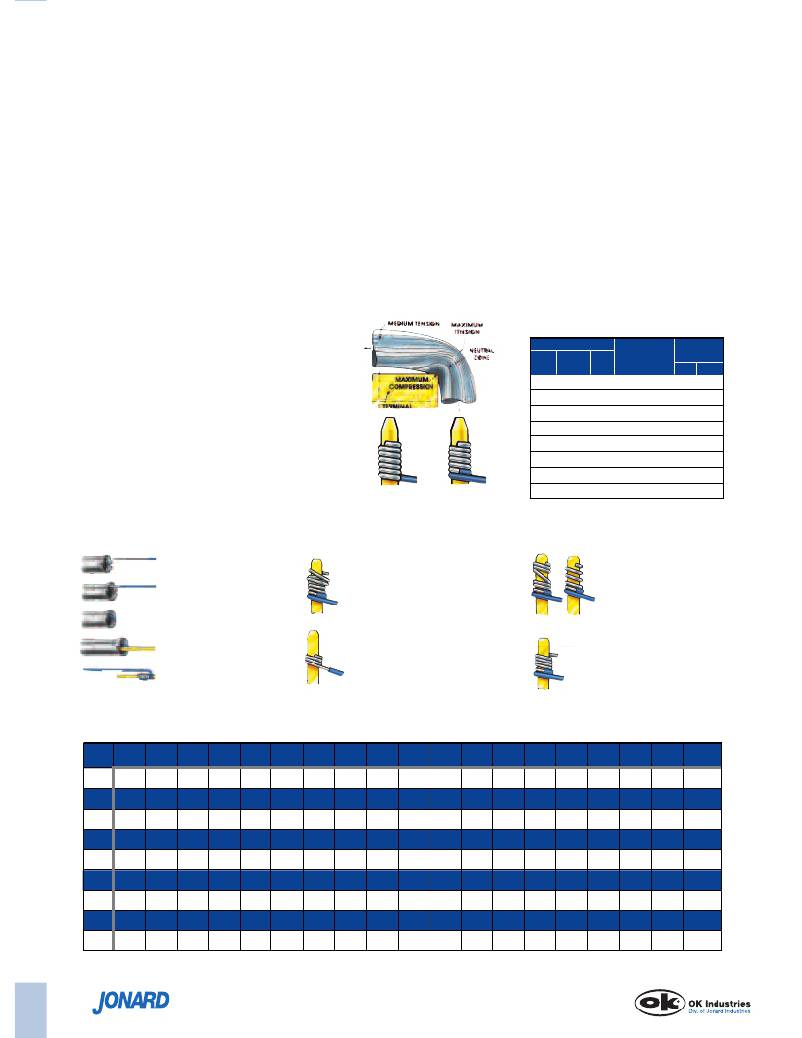

�TERMINAL� DIAGONAL� CHART�

�DIMENSION� B�

�In.�

�.010�

�.015�

�.020�

�.025�

�.030�

�.035� .040� .045�

�.050� .055� .060� .065�

�.070�

�.075�

�.080�

�.085�

�.090�

�.095�

�.100�

�mm� 0.25� 0.38� 0.51� 0.64� 0.76� 0.89� 1.02� 1.14�

�.010� .014� .018� .022� .027� .032� .036� .041� .046�

�0.25� 0.36� 0.46� 0.56� 0.69� 0.81� 0.91� 1.04� 1.17�

�.015� .018� .021� .025� .029� .033� .038� .043� .047�

�0.38� 0.46� 0.53� 0.64� 0.74� 0.84� 0.97� 1.09� 1.19�

�.020� .022� .025� .028� .032� .036� .040� .045� .049�

�0.51� 0.56� 0.64� 0.71� 0.81� 0.91� 1.02� 1.14� 1.25�

�.025� .027� .029� .032� .035� .039� .043� .047� .050�

�0.64� 0.69� 0.74� 0.81� 0.89� 0.99� 1.09� 1.19� 1.27�

�.030� .032� .033� .036� .039� .042� .046� .050� .054�

�0.76� 0.81� 0.84� 0.91� 0.99� 1.07� 1.17� 1.27� 1.37�

�.� 035� .036� .038� .040� .043� .046� .049� .052� .056�

�0.89� 0.91� 0.97� 1.02� 1.09� 1.17� 1.25� 1.32� 1.42�

�.040� .041� .043� .045� .047� .050� .052� .056� .060�

�1.02� 1.04� 1.09� 1.14� 1.19� 1.27� 1.32� 1.42� 1.52�

�.045� .046� .047� .049� .050� .054� .056� .060� .063�

�1.14� 1.17� 1.19� 1.25� 1.27� 1.37� 1.42� 1.52� 1.60�

�.050� .051� .052� .053� .056� .058� .060� .064� .067�

�1.27� 1.30� 1.32� 1.35� 1.42� 1.47� 1.52� 1.63� 1.70�

�1.27� 1.40� 1.52� 1.65�

�.051� .056� .061� .066�

�1.30� 1.42� 1.55� 1.68�

�.052� .057� .062� .067�

�1.32� 1.45� 1.58� 1.70�

�.053� .058� .063� .068�

�1.35� 1.47� 1.60� 1.73�

�.056� .060� .065� .069�

�1.42� 1.52� 1.65� 1.75�

�.058� .062� .067� .071�

�1.47� 1.58� 1.70� 1.80�

�.060� .064� .069� .073�

�1.52� 1.63� 1.75� 1.85�

�.064� .068� .072� .076�

�1.63� 1.73� 1.83� 1.93�

�.067� .071� .074� .078�

�1.70� 1.80� 1.88� 1.98�

�.071� .074� .078� .082�

�1.80� 1.88� 1.98� 2.08�

�1.78�

�.071�

�1.80�

�.072�

�1.83�

�.073�

�1.85�

�.074�

�1.88�

�.076�

�1.93�

�.078�

�1.98�

�.080�

�2.03�

�.083�

�2.11�

�.086�

�2.18�

�1.91�

�.076�

�1.93�

�.077�

�1.96�

�.078�

�1.98�

�.079�

�2.01�

�.080�

�2.03�

�.082�

�2.08�

�.084�

�2.13�

�.087�

�2.21�

�.090�

�2.29�

�2.03�

�.081�

�2.06�

�.082�

�2.08�

�.083�

�2.11�

�.084�

�2.13�

�.085�

�2.16�

�.087�

�2.21�

�.089�

�2.26�

�.091�

�2.31�

�.094�

�2.39�

�2.16�

�.086�

�2.18�

�.087�

�2.21�

�.088�

�2.24�

�.089�

�2.26�

�.090�

�2.29�

�.091�

�2.31�

�.092�

�2.34�

�.096�

�2.44�

�.098�

�2.49�

�2.29�

�.091�

�2.31�

�.092�

�2.34�

�.093�

�2.36�

�.094�

�2.39�

�.095�

�2.41�

�.096�

�2.44�

�.097�

�2.46�

�.101�

�2.57�

�.103�

�2.62�

�2.41�

�.096�

�2.44�

�.097�

�2.46�

�.098�

�2.49�

�.099�

�2.52�

�.100�

�2.54�

�.101�

�2.57�

�.102�

�2.59�

�.105�

�2.67�

�.107�

�2.72�

�2.54�

�.101�

�2.57�

�.102�

�2.59�

�.103�

�2.62�

�.104�

�2.64�

�.105�

�2.67�

�.106�

�2.69�

�.107�

�2.72�

�.109�

�2.77�

�.111�

�2.82�

�Example:� If� “A”=.020”.� “B”=.060”.� The� terminal� diagonal� is� .063"� as� shown� on� chart.�

�4�

�INDUSTRIES� CORP.�

�134� Marbledale� Road,� Tuckahoe,� NY� 10707�

�?� www.jonard.com�

�相关PDF资料 |

PDF描述 |

|---|---|

| 21236NA | SWITCH TOGGLE |

| 2641LH/2A21321L110V3 | SWITCH ROCKER DPST 16A 125V |

| 3EHT7M | FILTER RFI POWER LINE .250 3A |

| 2641LH/2A21321L220V3 | SWITCH ROCKER DPST 16A 125V |

| 445I32S24M00000 | CRYSTAL 24.00000 MHZ SERIES SMD |

相关代理商/技术参数 |

参数描述 |

|---|---|

| TK70J04J3(Q) | 制造商:Toshiba America Electronic Components 功能描述: |

| TK70J04K3Z | 制造商:TOSHIBA 制造商全称:Toshiba Semiconductor 功能描述:Switching Voltage Regulators DC-DC Converters Motor Drivers |

| TK70J20D | 制造商:TOSHIBA 制造商全称:Toshiba Semiconductor 功能描述:Switching Voltage Regulators |

| TK70S1A3B2T2 | 制造商:GREATECS 制造商全称:GREATECS 功能描述:High Capacity Toggle Switches up to 20A |

| TK70S3A3B2T2 | 制造商:GREATECS 制造商全称:GREATECS 功能描述:High Capacity Toggle Switches up to 20A |

发布紧急采购,3分钟左右您将得到回复。