- 您现在的位置:买卖IC网 > PDF目录67282 > TWR-5/3000-15/500-D12A-C (CD TECHNOLOGIES INC) 3-OUTPUT 20 W DC-DC REG PWR SUPPLY MODULE PDF资料下载

参数资料

| 型号: | TWR-5/3000-15/500-D12A-C |

| 厂商: | CD TECHNOLOGIES INC |

| 元件分类: | 电源模块 |

| 英文描述: | 3-OUTPUT 20 W DC-DC REG PWR SUPPLY MODULE |

| 封装: | ROHS COMPLIANT PACKAGE-8/7 |

| 文件页数: | 7/8页 |

| 文件大小: | 866K |

| 代理商: | TWR-5/3000-15/500-D12A-C |

MDC_TWR20W.A03 Page 7 of 8

TWR A-Series

20W, Triple Output DC/DC Converters

P O W E R E L E C T R O N I C S D I V I S I O N

D C / D C C O N V E R T E R S

www.cd4power.com

Quality and Reliability

The A-Series are the first DC/DC Converters to emerge from C&D’s new,

company-wide approach to designing and manufacturing the most reliable

power converters available. The five-pronged program draws our Quality

Assurance function into all aspects of new-product design, development,

characterization, qualification and manufacturing.

Design for Reliability

Design for Reliability is woven throughout our multi-phased, new-product-

development process. Design-for-reliability practices are fully documented

and begin early in the new-product development cycle with the following

goals:

. To work from an approved components/vendors list ensuring the use of

reliable components and the rigorous qualification of new components.

2. To design with safety margins by adhering to a strict set of derating

guidelines and performing theoretical worst-case analyses.

3. To locate potential design weaknesses early in the product-development

cycle by using extensive HALT (Highly Accelerated Life Testing).

4. To prove that early design improvements are effective by employing a

thorough FRACA (Failure Reporting Analysis and Corrective Action) system.

HALT Testing

The goal of the accelerated-stress techniques used by C&D is to force

device maturity, in a short period of time, by exposing devices to excessive

levels of "every stimulus of potential value." We use HALT (Highly Acceler-

ated Life Testing) repeatedly during the design and early manufacturing

phases to detect potential electrical and mechanical design weaknesses

that could result in possible future field failures.

During HALT, prototype and pre-production DC/DC converters are sub-

jected to progressively higher stress levels induced by thermal cycling,

rate of temperature change, vibration, power cycling, product-specific

stresses (such as dc voltage variation) and combined environments. The

stresses are not meant to simulate field environments but to expose any

weaknesses in a product’s electro/mechanical design and/or assem-

bly processes. The goal of HALT is to make products fail so that device

weaknesses can be analyzed and strengthened as appropriate. Applied

stresses are continually stepped up until products eventually fail. After

corrective actions and/or design changes, stresses are stepped up again

and the cycle is repeated until the "fundamental limit of the technology" is

determined.

C&D has invested in a Qualmark OVS- HALT tester capable of applying

voltage and temperature extremes as well as 6-axis, linear and rotational,

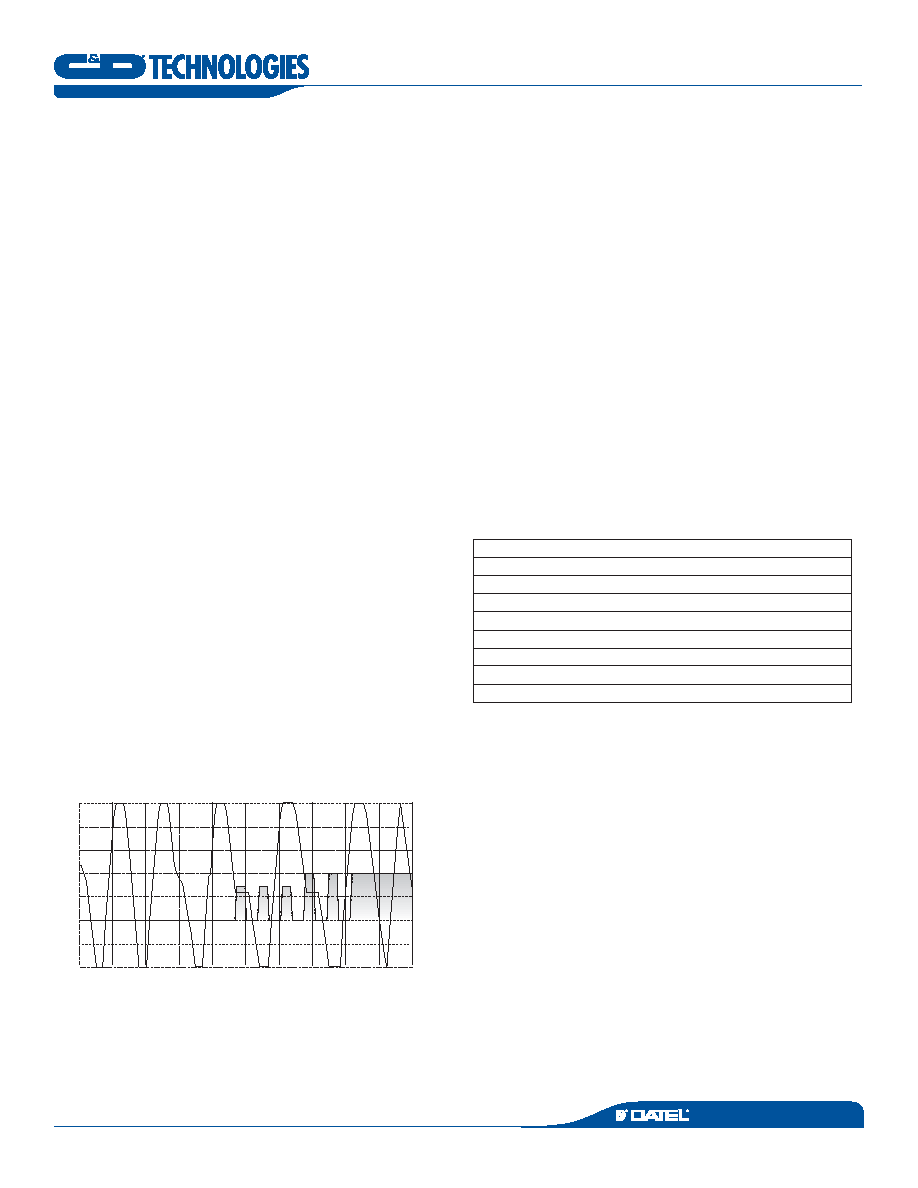

random vibration. A typical HALT profile (shown above) consists of thermal

cycling (–55 to +25°C, 30°C/minute) and simultaneous, gradually increas-

ing, random longitudinal and rotational vibration up to 20G’s with load

cycling and applied-voltage extremes added as desired. Many devices in

C&D’s A-Series could not be made to fail prior to reaching either the limits

of the HALT chamber or some previously known physical limit of the device.

We also use the HALT chamber and its ability to rapidly cool devices to

verify their "cold-start" capabilities.

Qualification

For each new product, electrical performance is verified via a comprehen-

sive characterization process and long-term reliability is confirmed via a

rigorous qualification procedure. The qual procedure includes such strenu-

ous tests as thermal shock and 500 hour life. Qual testing is summarized

below.

In-Line Process Controls and Screening

A combination of statistical sampling and 00% inspection techniques

keeps our assembly line under constant control. Parameters such as

solder-paste thickness, component placement, cleanliness, etc. are statisti-

cally sampled, charted and fine tuned as necessary. Visual inspections are

performed by trained operators after pick-and-place, soldering and cleaning

operations. Units are 00% electrically tested prior to potting. All devices

are temperature cycled, burned-in, hi-pot tested and final-electrical tested

prior to external visual examination, packing and shipping.

Rapid Response to Problems

C&D employs an outstanding corrective-action system to immediately

address any detected shortcomings in either products or processes. When-

ever our assembly, quality or engineering personnel spot a product/process

problem, or if a product is returned with a potential defect, we immediately

perform a detailed failure analysis and, if necessary, undertake corrective

actions. Over time, this system has helped refine our assembly operation to

yield one of the lowest product defect rates in the industry.

Typical HALT Profile

Qualification Test

Method/Comments

HALT

C&D in-house procedure

High Temperature Storage

Max. rated temp., ,000 hours

Thermal Shock

0 cycles, –55 to +25°C

Temperature/Humidity

+85°C, 85% humidity, 48 hours

Lead Integrity

C&D in-house procedure

Life Test

+70°C, 500 hours*

Marking Permanency

C&D in-house procedure

End Point Electrical Tests

Per product specification

Qualification Testing

* Interim electrical test at 200 hours.

10

20

30

40

50

60

70

80

90

40

20

0

Ra

nd

om

Vi

br

at

io

n

(G

's

)

Te

m

pe

ra

tu

re

(°

C)

Test Ti me (minutes)

100

80

60

40

20

0

–20

–40

相关PDF资料 |

PDF描述 |

|---|---|

| TWR-5/800-15/150-D5 | 3-OUTPUT DC-DC REG PWR SUPPLY MODULE |

| TWR-5/1000-12/210-D12 | 3-OUTPUT DC-DC REG PWR SUPPLY MODULE |

| TX20A-10R-D2GF1-A1LDE | 10 CONTACT(S), FEMALE, RIGHT ANGLE TELECOM AND DATACOM CONNECTOR, SURFACE MOUNT, RECEPTACLE |

| TX20A-14R-D2GF1-A1LE | 14 CONTACT(S), FEMALE, RIGHT ANGLE TELECOM AND DATACOM CONNECTOR, SURFACE MOUNT, RECEPTACLE |

| TX20A-26R-D2GF1-A1LDE | 26 CONTACT(S), FEMALE, RIGHT ANGLE TELECOM AND DATACOM CONNECTOR, SURFACE MOUNT, RECEPTACLE |

相关代理商/技术参数 |

参数描述 |

|---|---|

| TWR5300015500D48A | 制造商:Murata Power Solutions 功能描述: |

| TWR-5386 | 制造商:IDEC CORPORATION 功能描述:SEPERATE MTG TRANS |

| TWR-5486 | 制造商:IDEC CORPORATION 功能描述:Separate MTG TRANS 480VAC |

| TWR-56F8257 | 功能描述:开发板和工具包 - 其他处理器 MC56F8257 DSC TWR RoHS:否 制造商:Freescale Semiconductor 产品:Development Systems 工具用于评估:P3041 核心:e500mc 接口类型:I2C, SPI, USB 工作电源电压: |

| TWR-56F8400 | 功能描述:电源管理IC开发工具 56F8400 Twr Board HARDWARE ONLY RoHS:否 制造商:Maxim Integrated 产品:Evaluation Kits 类型:Battery Management 工具用于评估:MAX17710GB 输入电压: 输出电压:1.8 V |

发布紧急采购,3分钟左右您将得到回复。