- 您现在的位置:买卖IC网 > PDF目录17738 > ZAQ-3 (Omron Electronics Inc-IA Div)PANEL MOUNT PIN PLUNGER SHORT PDF资料下载

参数资料

| 型号: | ZAQ-3 |

| 厂商: | Omron Electronics Inc-IA Div |

| 文件页数: | 6/8页 |

| 文件大小: | 0K |

| 描述: | PANEL MOUNT PIN PLUNGER SHORT |

| 标准包装: | 1 |

| 附件类型: | 面板安装冲杆 |

| 适用于相关产品: | Omron X/Z 系列 |

| 其它名称: | ZAQ3 |

�� �

�

�

�Safety� Precautions�

�Be� sure� to� read� the� precautions� and� information� common� to� all� Snap� Action� and� Detection� Switches,� contained� in� the� Technical� User’s� Guide,�

�“Snap� Action� Switches,� Technical� Information”� for� correct� use.�

�Precautions� for� Safe� Use�

�Terminal� Connection�

�When� soldering� lead� wires� to� the� Switch,� make� sure� that� the� capacity�

�Incorrect�

�Correct�

�Separate� the�

�installation�

�location� from�

�heat� so� u� rces.�

�of� the� soldering� iron� is� 60� W� maximum.� Do� not� take� more� than� 5� s� to�

�solder� any� part� of� the� Switch.� The� characteristics� of� the� Switch� will�

�deteriorate� if� a� soldering� iron� with� a� capacity� of� more� than� 60� W� is�

�applied� to� any� part� of� the� Switch� for� 5� s� or� more.�

�Operation�

�?� Make� sure� that� the� switching� frequency� or� speed� is� within� the� spec-�

�?� Mount� a� cover� if� the� switch� is� to� be� installed� in� a� location� where�

�worker� inattention� could� result� in� incorrect� operation� or� accidents.�

�ified� range.�

�1.� If� the� switching� speed� is� extremely� slow,� the� contact� may� not� be�

�switched� smoothly,� which� may� result� in� a� contact� failure� or� contact�

�welding.�

�Incorrect�

�Correct�

�2.� If� the� switching� speed� is� extremely� fast,� switching� shock� may�

�damage� the� Switch� soon.� If� the� switching� frequency� is� too� high,�

�the� contact� may� not� catch� up� with� the� speed.�

�The� rated� permissible� switching� speed� and� frequency� indicate� the�

�switching� reliability� of� the� Switch.�

�The� life� of� a� Switch� is� determined� at� the� specified� switching�

�speed.� The� life� varies� with� the� switching� speed� and� frequency�

�even� when� they� are� within� the� permissible� ranges.� In� order� to�

�determine� the� life� of� a� Switch� model� to� be� applied� to� a� particular�

�use,� it� is� best� to� conduct� an� appropriate� durability� test� on� some�

�samples� of� the� model� under� actual� conditions.�

�?� Make� sure� that� the� actuator� travel� does� not� exceed� the� permissible�

�OT� position.� The� operating� stroke� must� be� set� to� 70%� to� 100%� of�

�the� rated� OT.�

�Precautions� for� Correct� Use�

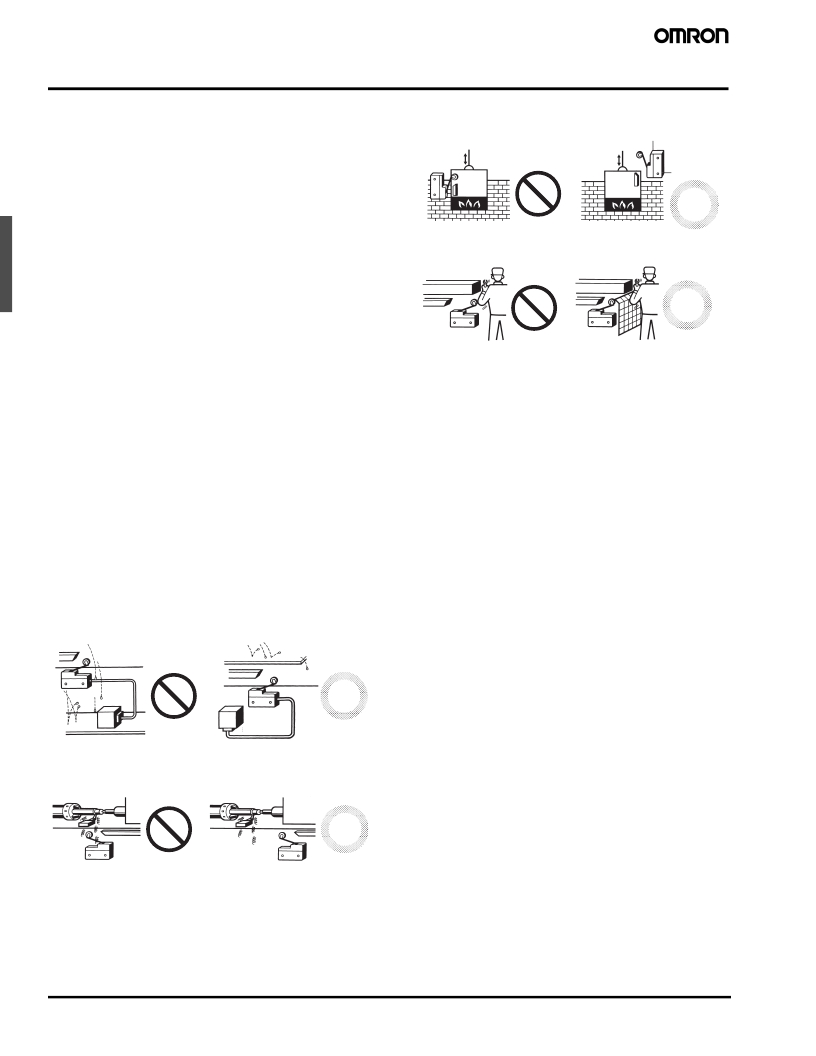

�Mounting� Location�

�?� Do� not� use� the� switch� alone� in� atmospheres� such� as� flammable� or�

�explosive� gases.� Arcing� and� heat� generation� associated� with�

�switching� may� cause� fires� or� explosions.�

�?� Switches� are� generally� not� constructed� with� resistance� against�

�water.� Use� a� protective� cover� to� prevent� direct� spraying� if� the� switch�

�is� used� in� locations� subject� to� splashing� or� spurting� oil� or� water,�

�dust� adhering.�

�(pre� v� en� ting malfunctions)�

�?� Subjecting� the� switch� to� continuous� vibration� or� shock� may� result� in�

�contact� failure,� faulty� operation� or� reduced� service� life� due� to�

�abrasion� powder.� Excessive� vibration� or� shock� will� cause� the� con-�

�tacts� to� operate� malfunction� or� become� damaged.� Mount� the� switch�

�in� a� location� that� is� not� subject� to� vibration� or� shock� and� in� a�

�direction� that� does� not� subject� the� switch� to� resonance.�

�?� If� silver� contacts� are� used� with� relatively� low� frequency� for� a� long�

�time� or� are� used� with� microloads,� the� sulfide� coating� produced� on�

�the� contact� surface� will� not� be� broken� down� and� contact� faults� will�

�result.� Use� a� microload� switch� that� uses� gold� contacts.�

�?� Do� not� use� the� switch� in� atmospheres� with� high� humidity� or� heat� or� in�

�harmful� gases,� such� as� sulfide� gas� (H� 2� S,� SO� 2� ),� ammonia� gas� (� N� H� 3� ),� nitric�

�acid� gas� (H� N� O� 3� ),� or� chlorine� gas� (Cl� 2� ).� Doing� so� may� impair� functionality,�

�such� as� with� damage� due� to� contacting� faults� or� corrosion.�

�?� The� switch� includes� contacts.� If� the� switch� is� used� in� an� atmosphere� with� silicon�

�gas,� arc� energy� may� cause� silicon� oxide� (SiO� 2� )� to� accumulate� on� the� contacts�

�and� result� in� contact� failure.� If� there� is� silicon� oil,� silicon� filling,� silicon� wiring,� or�

�other� silicon� products� in� the� vicinity� of� the� switch,� use� a� contact� protection� cir-�

�cuit� to� limit� arcing� and� remove� the� source� of� the� silicon� gas.�

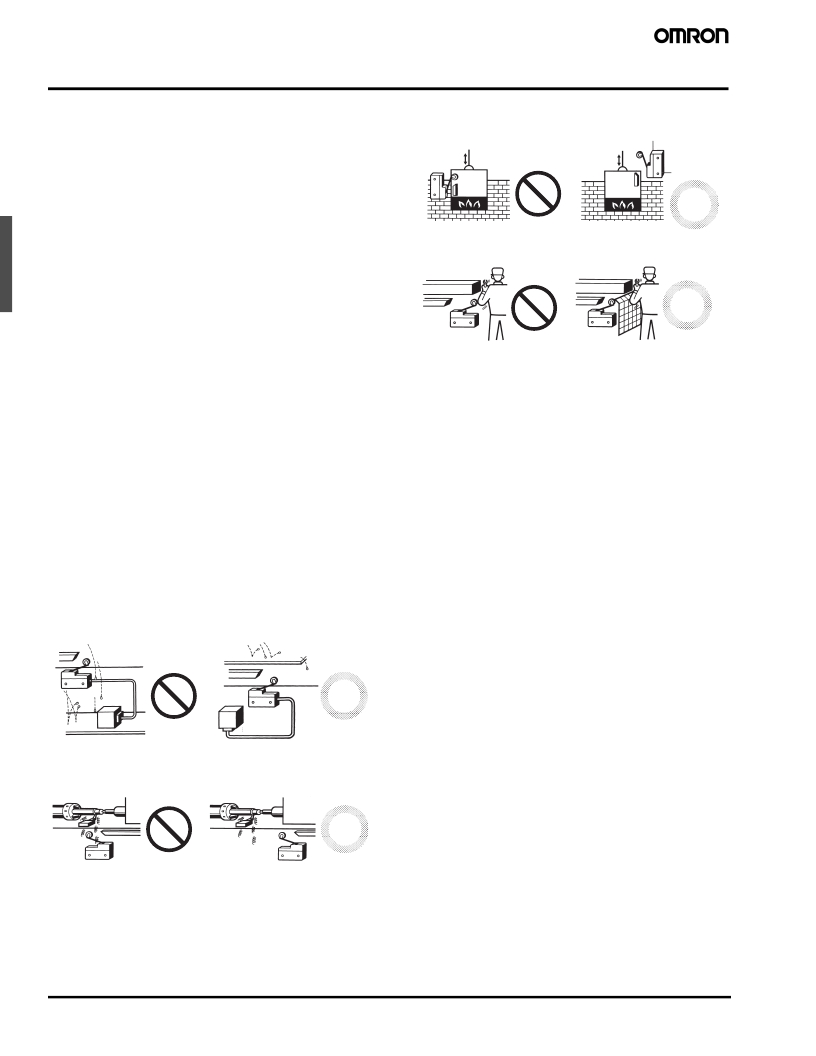

�Handling�

�?� Set� the� common� (COM)� terminal� to� the� positive� terminal.� If� it� is� set�

�to� the� negative� terminal,� the� Switch� will� not� turn� OFF.�

�Incorrect�

�Terminal� b� ox�

�Terminal� b� ox�

�Correct�

�?� When� using� the� Switch� under� an� inductive� load,� the� arc� suppression� capa-�

�bility� varies� depending� on� current.� If� the� current� becomes� 0.6� to� 1.2� A� or� of�

�the� time� constant� L/R� exceeds� 7� ms,� be� sure� to� provide� an� arc� suppressor.�

�?� Since� the� Switch� incorporates� a� permanent� magnet,� attention� must�

�be� paid� to� the� following� points:�

�(a)� Avoid� mounting� the� Switch� directly� onto� a� magnetic� substance.�

�(b)� Do� not� subject� the� Switch� to� severe� shocks.�

�(c)� Avoid� placing� the� Switch� in� a� strong� magnetic� field.�

�?� Install� the� switch� in� a� location� that� is� not� directly� subject� to� debris�

�and� dust� from� cutting.� The� actuator� and� the� switch� body� must� be�

�protected� from� accumulated� cutting� debris� and� dirt.�

�(d)� Be� sure� to� prevent� iron� dust� or� iron� chips� from� adhering� to� the�

�built-in� magnet� or� the� magnetic� blowout� function� of� the� Switch�

�will� be� adversely� affected.�

�Incorrect�

�Correct�

�(e)� Do� not� apply� thermal� shock� to� the� Switch,� or� the� magnetic� flux�

�will� be� diminished.�

�?� Since� a� ventilation� hole� is� provided� to� avoid� abnormal� corrosion� due�

�to� operating� conditions,� provide� a� dustproofing� device� in� locations�

�where� the� Switch� is� exposed� to� dust.�

�?� Do� not� change� operating� positions� for� the� actuator.� Changing� the�

�?� Do� not� use� the� switch� in� locations� subject� to� hot� water� (greater� than�

�60� °� C)� or� in� water� vapor.�

�?� Do� not� use� the� switch� outside� the� specified� temperature� and� atmo-�

�spheric� conditions.�

�The� permissible� ambient� temperature� depends� on� the� model.�

�(Refer� to� the� specifications� in� this� catalog.)� Sudden� thermal�

�changes� may� cause� thermal� shock� to� distort� the� switch� and� result�

�in� faults.�

�position� may� cause� malfunction.�

�Panel-mounted� Model� (X-10GQ� @� )�

�?� To� side-mount� the� panel-mount� Switch� to� the� panel� with� screws,�

�remove� the� hexagonal� nut� from� the� actuator.�

�?� Too� large� a� dog� angle� and� too� fast� operating� speed� may� damage�

�the� Switch� when� the� Switch� is� side-mounted� on� the� panel.�

�?� Too� fast� operating� speed� and� too� long� overtravel� of� the� roller�

�plunger� Switch� may� result� in� damage� to� the� Switch.�

�146�

�General-purpose� Basic� Switch�

�X�

�相关PDF资料 |

PDF描述 |

|---|---|

| MB2411S1W01 | SWITCH PUSHBUTTON SPDT 3A 125V |

| 3386G-1-254LF | TRIMMER 250K OHM 0.5W TH |

| PCA8885TS/Q900/1,1 | IC PROXIMITY SWITCH 8CH 28TSSOP |

| W2F15C1038AT1F | CAP FEEDTHRU .01UF 50V X7R 0805 |

| 3386G-1-253LF | TRIMMER 25K OHM 0.5W TH |

相关代理商/技术参数 |

参数描述 |

|---|---|

| ZAR2205-01A | 制造商:TDK CORPORATION OF AMERICA 功能描述:ZAR2205-01A \EMI Filters for Power Line |

| ZAR2210-01A | 制造商:TDK CORPORATION OF AMERICA 功能描述:ZAR2210-01A \EMI Filters for Power Line |

| ZAR2220-01A | 制造商:TDK CORPORATION OF AMERICA 功能描述:ZAR2220-01A \EMI Filters for Power Line |

| ZAR2230-01A | 制造商:TDK CORPORATION OF AMERICA 功能描述:ZAR2230-01A \EMI Filters for Power Line |

| ZAS13106205LRPN | 制造商:CTS Corporation 功能描述:- Bulk |

发布紧急采购,3分钟左右您将得到回复。