- 您现在的位置:买卖IC网 > PDF目录18581 > 0011010168 (Molex Inc)TOOL EXTRACTION FOR .084 CONTACT PDF资料下载

参数资料

| 型号: | 0011010168 |

| 厂商: | Molex Inc |

| 文件页数: | 15/24页 |

| 文件大小: | 0K |

| 描述: | TOOL EXTRACTION FOR .084 CONTACT |

| 标准包装: | 1 |

| 工具类型: | 拔出工具 |

| 适用于相关产品: | 0.084 英寸触点 |

| 产品目录页面: | 217 (CN2011-ZH PDF) |

| 配用: | 0002082006-ND - CONN TERM MALE 14-20AWG TIN 0002082005-ND - CONN TERM MALE 14-20AWG TIN 0002081004-ND - CONN FEMALE TERM 14-20AWG TIN WM2294CT-ND - TERM MALE PWR BRS TIN 14-20AWG WM2291CT-ND - TERMINAL MLX 14-20AWG FEMALE WM2294TR-ND - TERM MALE PWR BRS TIN 14-20AWG WM2291TR-ND - TERMINAL MLX 14-20AWG FEMALE WM1271CT-ND - CONN TERM FEMALE 14-20AWG TIN WM1271TR-ND - CONN TERM FEMALE 14-20AWG TIN WM1271-ND - CONN TERM FEMALE 14-20AWG TIN 更多... |

| 其它名称: | 0011-01-0168 0011-01-0168-E 0011010168-E 11-01-0168 11-01-0168-E 11010168 11010168-E HT60901 WM9921 |

�� �

�

�

�Quality� Crimp� Handbook�

�SECTION� 8�

�CRIMP� PROCESS� CONTROL�

�The� crimp� process� is� the� interaction� of� a� terminal,� wire,�

�tooling,� personnel,� methods� and� procedures,� and�

�environmental� attributes.� When� this� process� is�

�controlled,� it� will� produce� a� quality� termination.� Quality�

�control� is� an� important� part� of� quality� crimping.� It�

�should� not� take� excessive� setup� or� inspection� time� to�

�do,� and� it� can� save� a� harness� manufacturer� thousands�

�of� dollars� in� potential� rework� or� re-manufacturing.�

�Variability� is� the� slight� change� that� occurs� from� crimp� to�

�crimp.� There� are� two� types� of� variability,� common� or�

�special.� Common� causes� of� variation� affect� the�

�process� uniformly� and� are� the� result� of� many� small�

�sources.� Common� variability� is� inherent� tolerances�

�within� a� reel� of� wire� or� terminals.� Common� variability�

�also� is� created� by� the� natural� tolerances� of� the� stripping�

�and� crimping� machines.�

�Reducing� variability� at� the� common� level� typically� has�

�*� PPM� -� Parts� per� million� potential� defects.�

�A� 25� piece� minimum� sample� needs� to� be� taken� from�

�the� crimping� process.� Calculate� the� average� and�

�standard� deviation� for� the� sample.� A� capability� index� is�

�defined� by� the� formula� below.� C� p� may� range� in� value�

�from� zero� to� infinity,� with� a� larger� value� indicating� a�

�more� capable� process.� A� value� greater� than� 1.33� is�

�considered� acceptable� for� most� applications.� C� p� is�

�calculated� with� the� following� formula.�

�___Tolerance___�

�6*Standard� Deviation�

�The� C� pk� index� indicates� whether� the� process� will�

�produce� units� within� the� tolerance� limits.� C� pk� has� a�

�value� equal� to� C� p� if� the� process� is� centered� on� the�

�mean� of� specification;� if� C� pk� is� negative,� the� process�

�mean� is� outside� the� specification� limits;� if� C� pk� is�

�between� 0� and� 1� then� some� of� the� 6� sigma� spread� falls�

�outside� the� tolerance� limits.� If� C� pk� is� larger� than� one,�

�the� 6-sigma� spread� is� completely� within� the� tolerance�

�limits.� C� pk� is� calculated� with� the� lesser� of� the� following�

�formulas:�

�to� come� from� changes� to� the� wire,� terminal,� and� tooling�

�manufacturer.�

�__(USL - Mean)__�

�3*Standard� Deviation�

�__� (Mean� -� LSL)__�

�3*Standard� Deviation�

�Special� causes� of� variation� occur� irregularly� and�

�unpredictably.� Without� checks� throughout� a� run,� having�

�a� tool� become� loose� after� the� first� hundred� crimps� or� a�

�jam� resulting� from� a� damaged� tool� may� be� undetected�

�until� thousands� of� crimps� are� made.�

�Process� Capability�

�Before� putting� a� new� crimping� tool� in� production,� Molex�

�recommends� that� each� customer� do� a� capability� study,�

�using� the� specific� wire� that� will� be� used� in� its� process.�

�A� capability� study,� which� is� based� on� the� assumption� of�

�a� normal� distribution� (bell-type� curve),� estimates� the�

�probability� of� a� measurement� being� outside� of�

�specification.�

�USL� =� Upper� Specification� Limit,� LSL� =� Lower�

�Specification� Limit�

�Six� sigma� is� a� goal� of� many� companies� because� it�

�represents� virtually� zero� defects.� The� ability� of� a�

�company� to� achieve� a� six-sigma� level� depends� on� the�

�amount� of� common� variability� in� its� process.� For�

�example,� hand� stripping� the� wire� produces� more�

�variability� than� a� stripping� machine;� crimping� hand� tools�

�produce� more� variability� than� a� press� and� die� set,� and�

�bench� terminations� produce� more� variability� than� a�

�wire-processing� machine.�

�A� part� of� the� variability� in� crimping� will� result� from� the�

�type� of� instruments� that� are� used� to� measure� the� parts�

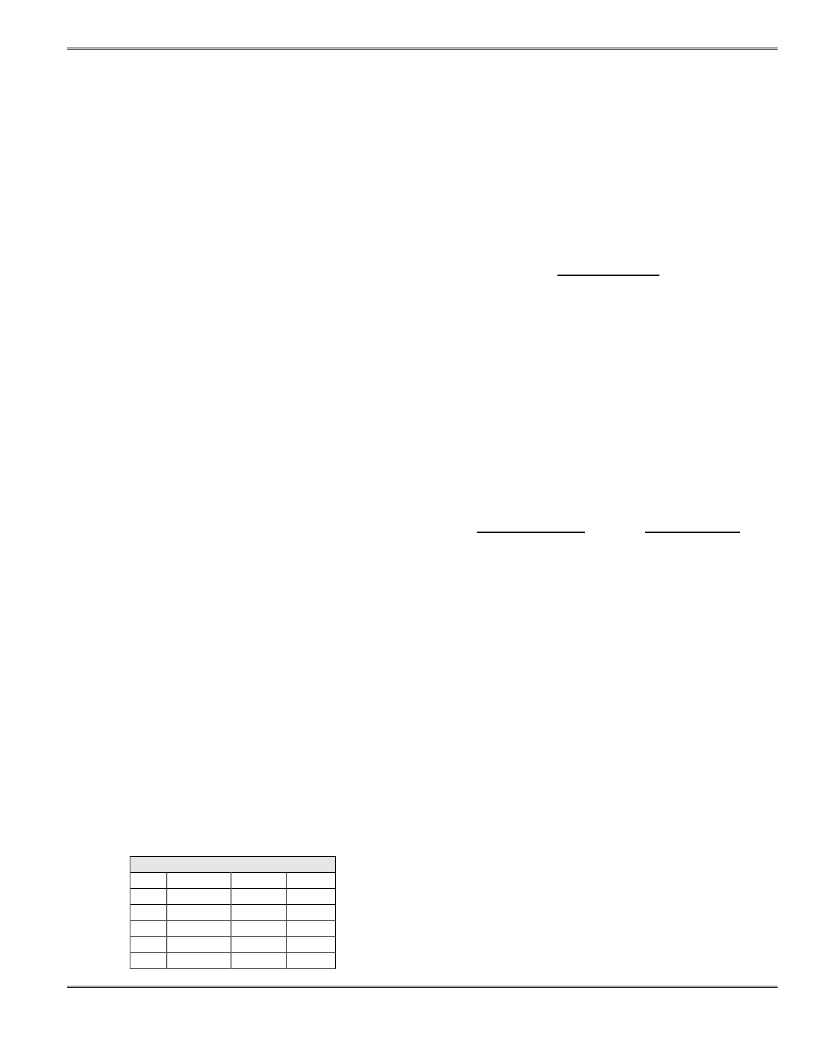

�C� pk�

�0.67�

�1�

�1.33�

�1.67�

�2�

�Capability�

�+/-� Sigma� %� Yield�

�2� 95.45�

�3� 99.73�

�4� 99.99�

�5� 99.99+�

�6� 99.99++�

�PPM*�

�45,500�

�2,699�

�63�

�0.57�

�0�

�and� the� operator's� ability� to� repeat� the� measurement.� A�

�crimp� micrometer� will� measure� more� accurately� than� a�

�dial� caliper.� An� automatic� pull� force� system� will�

�measure� better� than� a� hook� type� scale.� It� is� important�

�that� the� measurement� gauge� has� enough� resolution.�

�Order� No:� TM-638000029�

�Revision:� D�

�Release� Date:� 09-04-03�

�Revision� Date:� 12-23-09�

�UNCONTROLLED� COPY�

�Page� 15� of� 24�

�相关PDF资料 |

PDF描述 |

|---|---|

| 067000773001000 | HAND TOOL FOR 9176 SERIES |

| ABM2-48.000MHZ-D4YF-T | CRYSTAL 48.000 MHZ 18PF SMD |

| ASET-26.000MHZ-Y-T | OSC 26.000 MHZ 3.0V SMD |

| FQD8P10TF | MOSFET P-CH 100V 6.6A DPAK |

| CPPLC7L-B6-26.0000TS | OSCILLATOR 26.000MHZ SMD |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 0011010171 | 制造商:Molex 功能描述:OUTER JACKET STRIPPER - Bulk |

| 0011010172 | 制造商:Molex 功能描述:INNER TUBE CRIMP TOOL 制造商:Molex 功能描述:FTNER TUBE CRIMP TOOL - Bulk 制造商:Molex 功能描述:INNER CRIMP TOOL |

| 0011010173 | 制造商:Molex 功能描述:FTNER TUBE CRIMP JAWS - Bulk |

| 0011010180 | 制造商:Molex 功能描述:Hand Crimp Tool, Manual 制造商:Molex 功能描述:HAND TOOL FOR 41422 10-12 AWG |

| 0011-01-0180 | 制造商:MOLEX 制造商全称:Molex Electronics Ltd. 功能描述:Hand Crimper |

发布紧急采购,3分钟左右您将得到回复。