- 您现在的位置:买卖IC网 > PDF目录18581 > 0638132700 (Molex Inc)TOOL HAND EXTRACTION PDF资料下载

参数资料

| 型号: | 0638132700 |

| 厂商: | Molex Inc |

| 文件页数: | 7/24页 |

| 文件大小: | 0K |

| 描述: | TOOL HAND EXTRACTION |

| 标准包装: | 1 |

| 系列: | Sabre™ |

| 工具类型: | 拔出工具 |

| 适用于相关产品: | 线至线和线至板端子 |

| 产品目录页面: | 216 (CN2011-ZH PDF) |

| 配用: | 0476341002-ND - CONN TERM ATA PWR CBL RCPT GOLD 0357480410-ND - 1.8MM WTW CRP FEMALE TERM 0357480310-ND - 1.8MM TAB AND RCPT TERM 0357470410-ND - 1.8MM WTW CRP MALE TERM 0357460410-ND - 1.8MM WTW CRP FEMALE TERM 0357450410-ND - 1.8MM WTW CRP MALE TERM 0357255210-ND - CONN RCPT TERM 14-12AWG PRE-TIN 0357255110-ND - CONN RCPT TERM 18-14AWG PRE-TIN 0040021602-ND - 250 SPADE PUSH ON CRP TERM LIF 0040021601-ND - 250 SPADE PUSH ON CRP TERM LIF 更多... |

| 其它名称: | 063813-2700 063813-2700-E 0638132700-E 63813-2700 63813-2700-E 638132700 638132700-E WM9899 |

�� �

�

�

�Quality� Crimp� Handbook�

�To� evaluate� the� insulation� crimp� section,� cut� the� wire�

�Cut-off� Tab� Length�

�This� material� protrudes� outside� the� insulation� crimp�

�after� the� terminal� is� separated� from� the� carrier� strip.�

�As� a� rule,� the� cut-off� tab� is� approximately� 1.0� to� 1.5�

�times� terminal� material� thickness.� *� A� cut-off� tab�

�that� is� too� long� may� expose� a� terminal� outside� the�

�housing� or� it� may� fail� electrical� spacing�

�requirements.� In� most� situations,� a� tool� is� set� -� up� to�

�provide� a� cut-off� tab� that� is� flush� to� one� material�

�thickness.�

�Extrusions� (Flash)�

�These� small� flares� form� on� the� bottom� of� the�

�conductor� crimp� resulting� from� the� clearance�

�between� the� punch� and� anvil� tooling.� If� the� anvil� is�

�worn� or� the� terminal� is� over-crimped,� excessive�

�extrusion� is� the� results.� An� uneven� extrusion� may�

�also� result� if� the� punch� and� anvil� alignment� is� not�

�correct,� if� the� feed� adjustment� is� off,� or� if� there� is�

�insufficient/excessive� terminal� drag.�

�Insulation� Crimp� (Strain� Relief)�

�This� is� the� part� of� the� terminal� that� provides� wire�

�support� for� insertion� into� the� housing.� It� also� allows�

�the� terminal� to� withstand� shock� and� vibration.� The�

�terminal� needs� to� hold� the� wire� as� firmly� as� possible�

�without� cutting� through� to� the� conductor� strands.�

�The� acceptability� of� an� insulation� crimp� is� subjective�

�and� depends� on� the� application.� A� bend� test� is�

�recommended� to� determine� whether� the� strain� relief�

�is� acceptable� for� each� particular� application.�

�flush� with� the� back� of� the� terminal.� Once� the� optimum�

�setting� for� the� application� is� determined,� it� is� important� to�

�document� the� insulation� crimp� height.� Then,� as� part� of�

�the� setup� procedure,� the� operator� can� check� the� crimp�

�height.�

�Insulation� Position�

�This� is� the� location� of� the� insulation� in� relation� to� the�

�transition� area� between� the� conductor� and� insulation�

�crimps.� Equal� amounts� of� the� conductor� strands� and�

�insulation� needs� to� be� visible� in� the� transition� area.� The�

�insulation� position� ensures� that� the� insulation� is� crimped�

�along� the� full� length� of� the� insulation� crimp,� and� that� no�

�insulation� is� crimped� under� the� conductor� crimp.� The�

�insulation� position� is� set� by� the� wire� stop� and� strip� length�

�for� bench� applications.� For� automatic� wire� processing�

�applications,� the� insulation� position� is� set� by� the� in/out�

�press� adjustment.�

�Strip� Length�

�The� strip� length� is� determined� by� measuring� the�

�exposed� conductor� strands� after� the� insulation� is�

�removed.� The� strip� length� determines� the� conductor�

�brush� length� when� the� insulation� position� is� centered.�

�Figure� 4-2�

�*Consult� individual� terminal� specification� requirements�

�Insulation� Crimp� Height�

�Molex� does� not� specify� insulation� crimp� heights�

�Process�

�because� of� the� wide� variety� of� insulation� thickness,�

�material,� and� hardness.� Most� terminals� are�

�designed� to� accommodate� multiple� wire� ranges.�

�Within� the� terminal’s� range,� the� strain� relief� may� or�

�may� not� completely� surround� the� diameter� of� the�

�wire.� This� condition� will� still� provide� an� acceptable�

�insulation� crimp� for� most� applications.�

�1.� A� large� strain� relief� should� firmly� grip� at� least�

�88%� of� the� wire.�

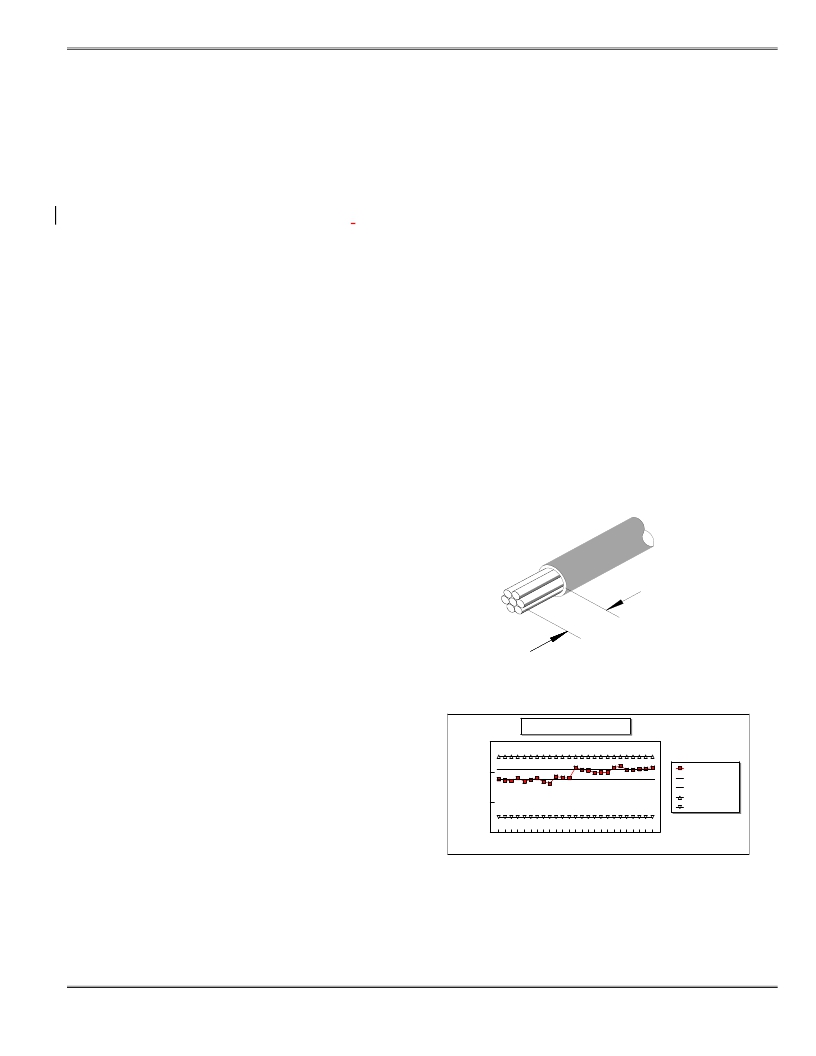

�31.5�

�30.5�

�29.5�

�28.5�

�Example Control Chart�

�1� 2� 3� 4� 5� 6� 7� 8� 9� 10� 11� 12� 13� 14� 15� 16� 17� 18� 19� 20� 21� 22� 23� 24� 25�

�Measurements�

�Figure� 4-3�

�Sample�

�Contol� Limit�

�Control� Limit�

�Upper� Specification�

�Lower� Specification�

�2.� A� smaller� strain� relief� should� firmly� grip� at� least�

�50%� of� the� wire� and� firmly� hold� the� top� of� the�

�wire.�

�The� combination� of� people,� equipment,� tooling,�

�materials,� methods,� and� procedures� needed� to� produce�

�a� crimp� termination.� Process� Control� is� used� to� track�

�attributes� over� time� to� aid� in� the� detection� of� change� to�

�Order� No:� TM-638000029�

�Revision:� D�

�Release� Date:� 09-04-03�

�Revision� Date:� 12-23-09�

�UNCONTROLLED� COPY�

�Page� 7� of� 24�

�相关PDF资料 |

PDF描述 |

|---|---|

| ABM2-15.000MHZ-D4Y-T | CRYSTAL 15.000 MHZ 18PF SMD |

| SI7388DP-T1-E3 | MOSFET N-CH 30V PPAK 8SOIC |

| ABM2-32.000MHZ-D4YF-T | CRYSTAL 32.000 MHZ 18PF SMD |

| ASVMPC-14.31818MHZ-Z-T | OSC 14.31818 MHZ CMOS MEMS SMD |

| P149 | TOOL HAND INSERTION FOR T42-1 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 0638132800 | 功能描述:EXTRACTION TOOL RoHS:否 类别:工具 >> 插入,抽取 系列:* 标准包装:1 系列:* 其它名称:0011-03-00080011-03-0008-E00110300080011030008-E11-03-0008-E1103000811030008-EQ4729393AT0980176A |

| 0638132900 | 制造商:Molex 功能描述:EXTRACTION TOOL 制造商:Molex 功能描述:EXTRACTION TOOL - Bulk |

| 0638133100 | 功能描述:EXTRACTION TOOL RoHS:否 类别:工具 >> 插入,抽取 系列:* 标准包装:1 系列:* 其它名称:0011-03-00080011-03-0008-E00110300080011030008-E11-03-0008-E1103000811030008-EQ4729393AT0980176A |

| 0638133200 | 功能描述:EXTRACTOR TOOL RoHS:否 类别:工具 >> 插入,抽取 系列:* 标准包装:1 系列:* 其它名称:0011-03-00080011-03-0008-E00110300080011030008-E11-03-0008-E1103000811030008-EQ4729393AT0980176A |

| 0638133300 | 功能描述:EXTRACTOR TOOL RoHS:否 类别:工具 >> 插入,抽取 系列:* 标准包装:1 系列:* 其它名称:0011-03-00080011-03-0008-E00110300080011030008-E11-03-0008-E1103000811030008-EQ4729393AT0980176A |

发布紧急采购,3分钟左右您将得到回复。