- 您现在的位置:买卖IC网 > PDF目录368401 > PZ5128-S10BE-S Electrically-Erasable Complex PLD PDF资料下载

参数资料

| 型号: | PZ5128-S10BE-S |

| 英文描述: | Electrically-Erasable Complex PLD |

| 中文描述: | 电可擦除复杂可编程逻辑器件 |

| 文件页数: | 8/22页 |

| 文件大小: | 180K |

| 代理商: | PZ5128-S10BE-S |

Philips Semiconductors

Product specification

PZ5128

128 macrocell CPLD

1997 Aug 12

8

JTAG Testing Capability

JTAG is the commonly-used acronym for the Boundary Scan Test

(BST) feature defined for integrated circuits by IEEE Standard

1149.1. This standard defines input/output pins, logic control

functions, and commands which facilitate both board and device

level testing without the use of specialized test equipment. BST

provides the ability to test the external connections of a device, test

the internal logic of the device, and capture data from the device

during normal operation. BST provides a number of benefits in each

of the following areas:

Testability

–

Allows testing of an unlimited number of interconnects on the

printed circuit board

–

Testability is designed in at the component level

–

Enables desired signal levels to be set at specific pins (Preload)

–

Data from pin or core logic signals can be examined during

normal operation

Reliability

–

Eliminates physical contacts common to existing test fixtures

(e.g., “bed-of-nails”)

–

Degradation of test equipment is no longer a concern

–

Facilitates the handling of smaller, surface-mount components

–

Allows for testing when components exist on both sides of the

printed circuit board

Cost

–

Reduces/eliminates the need for expensive test equipment

–

Reduces test preparation time

–

Reduces spare board inventories

The Philips PZ5128’s JTAG interface includes a TAP Port and a TAP

Controller, both of which are defined by the IEEE 1149.1 JTAG

Specification. As implemented in the Philips PZ5128, the TAP Port

includes four of the five pins (refer to Table 3) described in the JTAG

specification: TCK, TMS, TDI, and TDO. The fifth signal defined by

the JTAG specification is TRST* (Test Reset). TRST* is considered

an optional signal, since it is not actually required to perform BST or

ISP. The Philips PZ5128 saves an I/O pin for general purpose use

by not implementing the optional TRST* signal in the JTAG

interface. Instead, the Philips PZ5128 supports the test reset

functionality through the use of its power up reset circuit, which is

included in all Philips CPLDs. The pins associated with the power up

reset circuit should connect to an external pull-up resistor to keep

the JTAG signals from floating when they are not being used.

In the Philips PZ5128, the four mandatory JTAG pins each require a

unique, dedicated pin on the device. However, if JTAG and ISP are

not desired in the end-application, these pins may instead be used

as additional general I/O pins. The decision as to whether these pins

are used for JTAG/ISP or as general I/O is made when the JEDEC

file is generated. If the use of JTAG/ISP is selected, the dedicated

pins are not available for general purpose use. However, unlike

competing CPLD’s, the Philips PZ5128 does allow the macrocell

logic associated with these dedicated pins to be used as buried logic

even when JTAG/ISP is selected. Table 4 defines the dedicated pins

used by the four mandatory JTAG signals for each of the PZ5128

package types.

The JTAG specifications defines two sets of commands to support

boundary-scan testing: high-level commands and low-level

commands. High-level commands are executed via board test

software on an a user test station such as automated test

equipment, a PC, or an engineering workstation (EWS). Each

high-level command comprises a sequence of low level commands.

These low-level commands are executed within the component

under test, and therefore must be implemented as part of the TAP

Controller design. The set of low-level boundary-scan commands

implemented in the Philips PZ5128 is defined in Table 5. By

supporting this set of low-level commands, the PZ5128 allows

execution of all high-level boundary-scan commands.

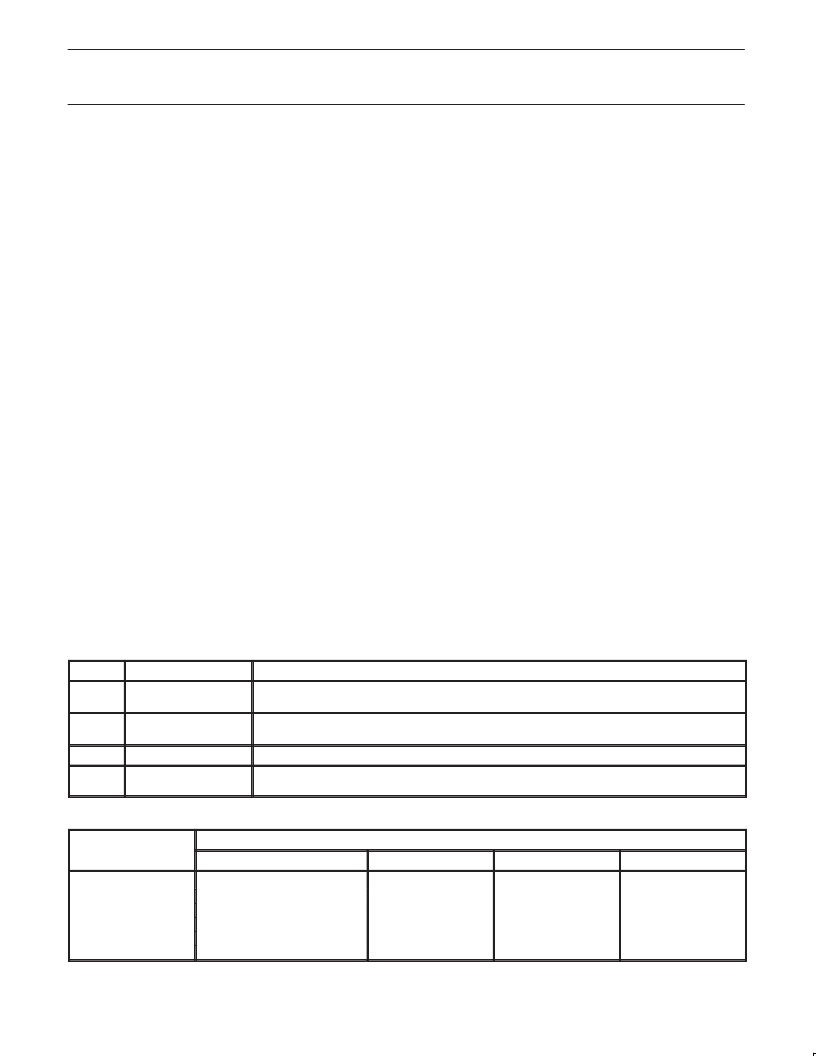

Table 3. JTAG Pin Description

PIN

NAME

DESCRIPTION

TCK

Test Clock Output

Clock pin to shift the serial data and instructions in and out of the TDI and TDO pins, respectively.

TCK is also used to clock the TAP Controller state machine.

TMS

Test Mode Select

Serial input pin selects the JTAG instruction mode. TMS should be driven high during user mode

operation.

TDI

Test Data Input

Serial input pin for instructions and test data. Data is shifted in on the rising edge of TCK.

TDO

Test Data Output

Serial output pin for instructions and test data. Data is shifted out on the falling edge of TCK. The

signal is tri-stated if data is not being shifted out of the device.

Table 4. PZ5128 JTAG Pinout by Package Type

DEVICE

(PIN NUMBER / MACROCELL #)

TCK

TMS

TDI

TDO

PZ5128

84-pin PLCC

100-pin PQFP

100-pin TQFP

128-pin LQFP

160-pin PQFP

62 / 96 (F15)

64 / 96 (F15)

62 / 96 (F15)

82 / 96 (F15)

99 / 96 (F15)

23 / 48 (C15)

17 / 48 (C15)

15 / 48 (C15)

21 / 48 (C15)

22 / 48 (C15)

14 / 32 (B15)

6 / 32 (B15)

4 / 32 (B15)

8 / 32 (B15)

9 / 32 (B15)

71 / 112 (G15)

75 / 112 (G15)

73 / 112 (G15)

95 / 112 (G15)

112/ 112 (G15)

相关PDF资料 |

PDF描述 |

|---|---|

| PZ5128-S10BP | Electrically-Erasable Complex PLD |

| PZ5128-S10BP-S | Electrically-Erasable Complex PLD |

| PZ5128-S12A84 | Electrically-Erasable Complex PLD |

| PZ5128-S12BB1 | Electrically-Erasable Complex PLD |

| PZ5128-S12BB1-S | Electrically-Erasable Complex PLD |

相关代理商/技术参数 |

参数描述 |

|---|---|

| PZ5128-S7BP | 制造商: 功能描述: 制造商:undefined 功能描述: |

| PZ-5-3 | 制造商:WM BERG 功能描述: |

| PZ5CG | 制造商:未知厂家 制造商全称:未知厂家 功能描述:0.5 KV ISOLATED 0.75 W REGULATED SINGLE OUTPUT SIP7 |

| PZ5CG-0505E | 制造商:未知厂家 制造商全称:未知厂家 功能描述:0.5 KV ISOLATED 0.75 W REGULATED SINGLE OUTPUT SIP7 |

| PZ5CG-0512E | 制造商:未知厂家 制造商全称:未知厂家 功能描述:0.5 KV ISOLATED 0.75 W REGULATED SINGLE OUTPUT SIP7 |

发布紧急采购,3分钟左右您将得到回复。