- 您现在的位置:买卖IC网 > PDF目录98170 > TC642BEOA713 BRUSHLESS DC MOTOR CONTROLLER, PDSO8 PDF资料下载

参数资料

| 型号: | TC642BEOA713 |

| 元件分类: | 运动控制电子 |

| 英文描述: | BRUSHLESS DC MOTOR CONTROLLER, PDSO8 |

| 封装: | 0.150 INCH, PLASTIC, SOIC-8 |

| 文件页数: | 9/34页 |

| 文件大小: | 683K |

| 代理商: | TC642BEOA713 |

第1页第2页第3页第4页第5页第6页第7页第8页当前第9页第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页

2003 Microchip Technology Inc.

DS21756B-page 17

TC642B/TC647B

5.0

APPLICATIONS INFORMATION

5.1

Setting the PWM Frequency

The PWM frequency of the VOUT output is set by the

capacitor value attached to the CF pin. The PWM fre-

quency will be 30 Hz (typical) for a 1 F capacitor. The

relationship between frequency and capacitor value is

linear, making alternate frequency selections easy.

As stated in previous sections, the PWM frequency

should be kept in the range of 15 Hz to 35 Hz. This will

eliminate the possibility of having audible frequencies

when varying the duty cycle of the fan drive.

A very important factor to consider when selecting the

PWM frequency for the TC642B/TC647B devices is the

RPM rating of the selected fan and the minimum duty

cycle that the fan will be operating at. For fans that have

a full speed rating of 3000 RPM or less, it is desirable

to use a lower PWM frequency. A lower PWM fre-

quency allows for a longer time period to monitor the

fan current pulses. The goal is to be able to monitor at

least two fan current pulses during the on time of the

VOUT output.

Example: The system design requirement is to operate

the fan at 50% duty cycle when ambient temperatures

are below 20°C. The fan full speed RPM rating is

3000 RPM and has four current pulses per rotation. At

50% duty cycle, the fan will be operating at

approximately 1500 RPM.

EQUATION

If one fan revolution occurs in 40 msec, each fan pulse

occurs 10 msec apart. In order to detect two fan current

pulses, the on time of the VOUT pulse must be at least

20 msec. With the duty cycle at 50%, the total period of

one cycle must be at least 40 msec, which makes the

PWM frequency 25 Hz. For this example, a PWM fre-

quency of 20 Hz is recommended. This would define a

CF capacitor value of 1.5 F.

5.2

Temperature Sensor Design

As discussed in previous sections, the VIN analog input

has a range of 1.20V to 2.60V (typical), which repre-

sents a duty cycle range on the VOUT output of 0% to

100%, respectively. The VIN voltages can be thought of

as representing temperatures. The 1.20V level is the

low temperature at which the system requires very little

cooling. The 2.60V level is the high temperature, for

which the system needs maximum cooling capability

(100% fan speed).

One of the simplest ways of sensing temperature over

a given range is to use a thermistor. By using an NTC

thermistor, as shown in Figure 5-1, a temperature

variant voltage can be created.

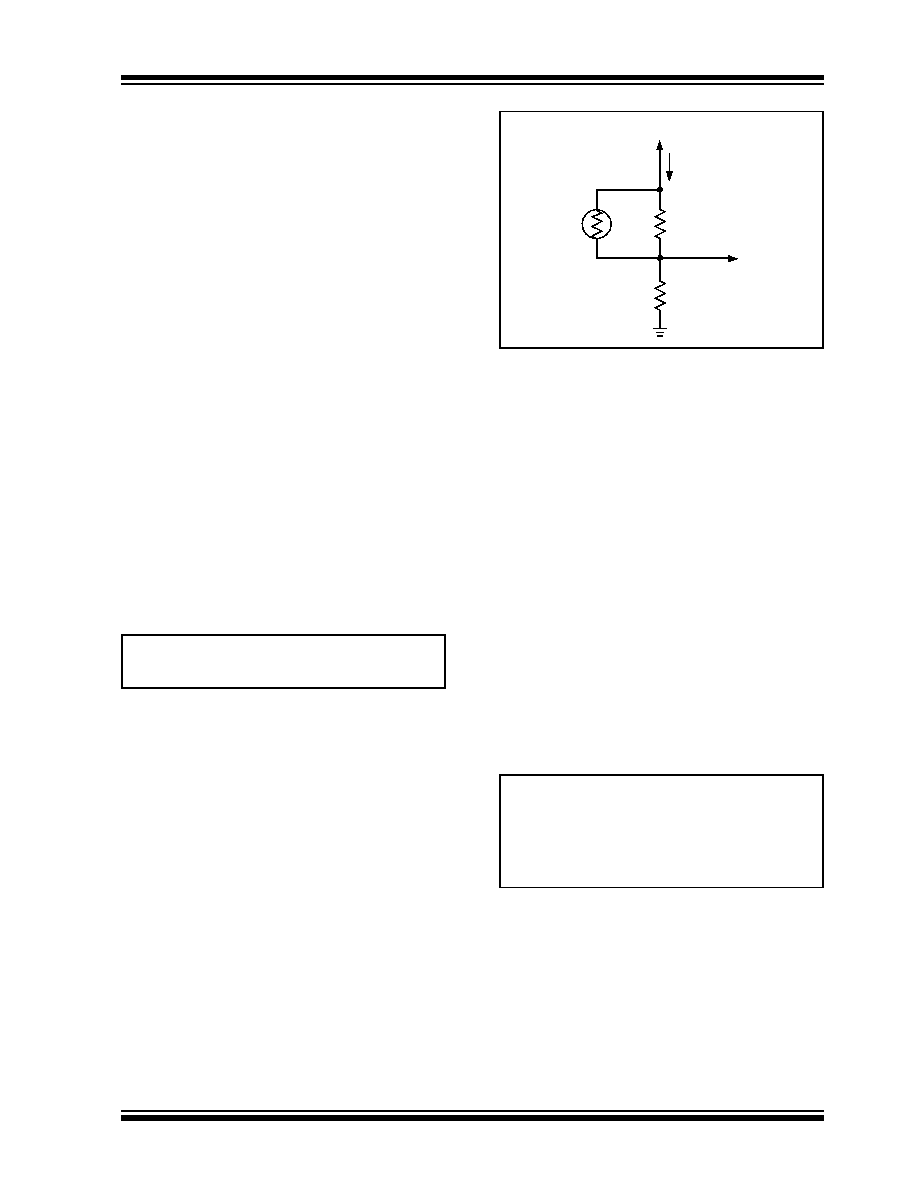

FIGURE 5-1:

Temperature Sensing

Circuit.

Figure 5-1 represents a temperature-dependent volt-

age divider circuit. RT is a conventional NTC thermistor,

while R1 and R2 are standard resistors. R1 and RT form

a parallel resistor combination that will be referred to as

RTEMP (RTEMP = R1 * RT / R1 + RT). As the temperature

increases, the value of Rt decreases and the value of

RTEMP will decrease with it. Accordingly, the voltage at

VIN increases as temperature increases, giving the

desired relationship for the VIN input. R1 helps to linear-

ize the response of the sense network and aids in

obtaining the proper VIN voltages over the desired tem-

perature range. An example of this is shown in

If less current draw from VDD is desired, a larger value

thermistor should be chosen. The voltage at the VIN pin

can also be generated by a voltage output temperature

sensor device. The key is to get the desired VIN voltage

to system (or component) temperature relationship.

The following equations apply to the circuit in

EQUATION

In order to solve for the values of R1 and R2, the values

for VIN, and the temperatures at which they are to

occur, need to be selected. The variables T1 and T2

represent the selected temperatures. The value of the

thermistor at these two temperatures can be found in

the thermistor data sheet. With the values for the ther-

mistor and the values for VIN, there are now two

equations from which the values for R1 and R2 can be

found.

Time for one revolution (msec.)

60 1000

×

1500

------------------------40

==

R2

R1

RT

IDIV

VIN

VDD

VT1

()

VDD R2

×

RTEMP T1

() R2

+

------------------------------------------

=

VT2

()

VDD R2

×

RTEMP T2

() R2

+

------------------------------------------

=

相关PDF资料 |

PDF描述 |

|---|---|

| TC647BEUA | BRUSHLESS DC MOTOR CONTROLLER, PDSO8 |

| TC642BEOA | BRUSHLESS DC MOTOR CONTROLLER, PDSO8 |

| TC647EOATR | BRUSHLESS DC MOTOR CONTROLLER, PDSO8 |

| TC647VUATR | BRUSHLESS DC MOTOR CONTROLLER, PDSO8 |

| TC647VOART | BRUSHLESS DC MOTOR CONTROLLER, PDSO8 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| TC642BEOAG | 制造商:Microchip Technology 功能描述:Fan Control Demo Board |

| TC642BEOATR | 制造商:MICROCHIP 制造商全称:Microchip Technology 功能描述:PWM Fan Speed Controllers With Minimum Fan Speed, Fan Restart and FanSense⑩ Technology for Fault Detection |

| TC642BEPA | 功能描述:马达/运动/点火控制器和驱动器 w/Rstrt & Flt Dtct RoHS:否 制造商:STMicroelectronics 产品:Stepper Motor Controllers / Drivers 类型:2 Phase Stepper Motor Driver 工作电源电压:8 V to 45 V 电源电流:0.5 mA 工作温度:- 25 C to + 125 C 安装风格:SMD/SMT 封装 / 箱体:HTSSOP-28 封装:Tube |

| TC642BEPA713 | 制造商:MICROCHIP 制造商全称:Microchip Technology 功能描述:PWM Fan Speed Controllers With Minimum Fan Speed, Fan Restart and FanSense⑩ Technology for Fault Detection |

| TC642BEPATR | 制造商:MICROCHIP 制造商全称:Microchip Technology 功能描述:PWM Fan Speed Controllers With Minimum Fan Speed, Fan Restart and FanSense⑩ Technology for Fault Detection |

发布紧急采购,3分钟左右您将得到回复。