- 您现在的位置:买卖IC网 > PDF目录97629 > MTV10N100E (ON SEMICONDUCTOR) 10 A, 1000 V, 1.3 ohm, N-CHANNEL, Si, POWER, MOSFET PDF资料下载

参数资料

| 型号: | MTV10N100E |

| 厂商: | ON SEMICONDUCTOR |

| 元件分类: | JFETs |

| 英文描述: | 10 A, 1000 V, 1.3 ohm, N-CHANNEL, Si, POWER, MOSFET |

| 封装: | D3PAK-3 |

| 文件页数: | 8/10页 |

| 文件大小: | 269K |

| 代理商: | MTV10N100E |

MTV10N100E

7

Motorola TMOS Power MOSFET Transistor Device Data

INFORMATION FOR USING THE DPAK SURFACE MOUNT PACKAGE

RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the total

design. The footprint for the semiconductor packages must be

the correct size to ensure proper solder connection interface

between the board and the package. With the correct pad

geometry, the packages will self align when subjected to a

solder reflow process.

0.190

4.826

mm

inches

0.100

2.54

0.063

1.6

0.165

4.191

0.118

3.0

0.243

6.172

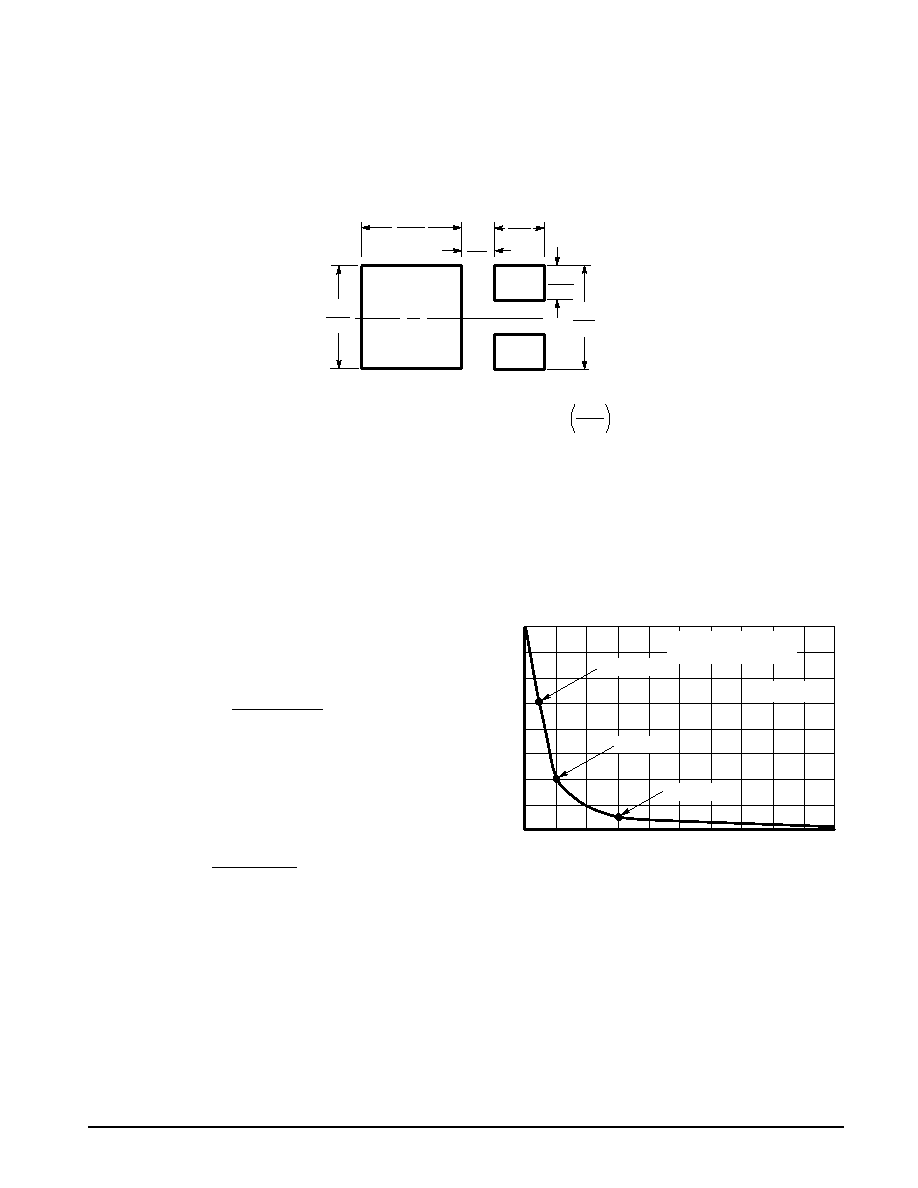

POWER DISSIPATION FOR A SURFACE MOUNT DEVICE

The power dissipation for a surface mount device is a

function of the drain pad size.

These can vary from the

minimum pad size for soldering to a pad size given for

maximum power dissipation. Power dissipation for a surface

mount device is determined by TJ(max), the maximum rated

junction temperature of the die, R

θJA, the thermal resistance

from the device junction to ambient, and the operating

temperature, TA. Using the values provided on the data sheet,

PD can be calculated as follows:

PD =

TJ(max) – TA

R

θJA

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values into

the equation for an ambient temperature TA of 25°C, one can

calculate the power dissipation of the device. For a D3PAK

device, PD is calculated as follows.

PD =

150

°C – 25°C

62.5

°C/W

= 2.0 Watts

The 62.5

°C/W for the D3PAK package assumes the use of

the recommended footprint on a glass epoxy printed circuit

board to achieve a power dissipation of 2.0 Watts. There are

other alternatives to achieving higher power dissipation from

the surface mount packages. One is to increase the area of the

drain pad. By increasing the area of the drain pad, the power

dissipation can be increased. Although one can almost double

the power dissipation with this method, one will be giving up

area on the printed circuit board which can defeat the purpose

of using surface mount technology. For example, a graph of

R

θJA versus drain pad area is shown in Figure 15.

Figure 16. Thermal Resistance versus Drain Pad

Area for the D3PAK Package (Typical)

1.75 Watts

Board Material = 0.0625

″

G–10/FR–4, 2 oz Copper

80

100

60

40

20

10

8

6

4

2

0

3.0 Watts

5.0 Watts

TA = 25°C

A, AREA (SQUARE INCHES)

T

O

AMBIENT

(

C/W)°

R

JA

,THERMAL

RESIST

ANCE,

JUNCTION

θ

Another alternative would be to use a ceramic substrate or

an aluminum core board such as Thermal Clad

. Using a

board material such as Thermal Clad, an aluminum core

board, the power dissipation can be doubled using the same

footprint.

相关PDF资料 |

PDF描述 |

|---|---|

| MTV10N100E-RL | 10 A, 1000 V, 1.3 ohm, N-CHANNEL, Si, POWER, MOSFET |

| MTW6N100EG | 6 A, 1000 V, 1.5 ohm, N-CHANNEL, Si, POWER, MOSFET, TO-247AE |

| MUN2112 | 100 mA, 50 V, PNP, Si, SMALL SIGNAL TRANSISTOR |

| MUN2214 | 100 mA, 50 V, NPN, Si, SMALL SIGNAL TRANSISTOR |

| MUN2212 | 100 mA, 50 V, NPN, Si, SMALL SIGNAL TRANSISTOR |

相关代理商/技术参数 |

参数描述 |

|---|---|

| MTV1-100SL1 | 制造商:ITT Interconnect Solutions 功能描述:MTV1-100SL1 - Bulk |

| MTV1-102SL1 | 制造商:ITT Interconnect Solutions 功能描述:MTV1-102SL1 - Bulk |

| MTV1-102SS | 制造商:ITT Interconnect Solutions 功能描述:MTV1-102SS - Bulk |

| MTV1-104PL1 | 制造商:ITT Interconnect Solutions 功能描述:MTV1-104PL1 - Bulk |

| MTV1-104SL1 | 制造商:ITT Interconnect Solutions 功能描述:MTV1-104SL1 - Bulk |

发布紧急采购,3分钟左右您将得到回复。