- 您现在的位置:买卖IC网 > Datasheet目录596 > 312253-2 (TE Connectivity)CONN SMA DIE/SET 50OHM RG402 2PC Datasheet资料下载

参数资料

| 型号: | 312253-2 |

| 厂商: | TE Connectivity |

| 文件页数: | 10/12页 |

| 文件大小: | 0K |

| 描述: | CONN SMA DIE/SET 50OHM RG402 2PC |

| 标准包装: | 1 |

| 压接或电缆尺寸: | RG/U-402 |

| 压接手柄: | A9966-ND |

| 连接器类型: | SMA |

| 产品目录页面: | 453 (CN2011-ZH PDF) |

| 配用: | 413249-1-ND - CONTACT JACK COAX 405SR 413242-1-ND - CONTACT PLUG BLIND MATE STR GOLD |

| 相关产品: | A9966-ND - TOOL SMA CRIMP FRAME ONLY |

| 其它名称: | A9964 |

�� �

�

�

�408-6788�

�9.1.� Daily� Maintenance�

�1.� Remove� dust,� moisture,� and� other� contaminants�

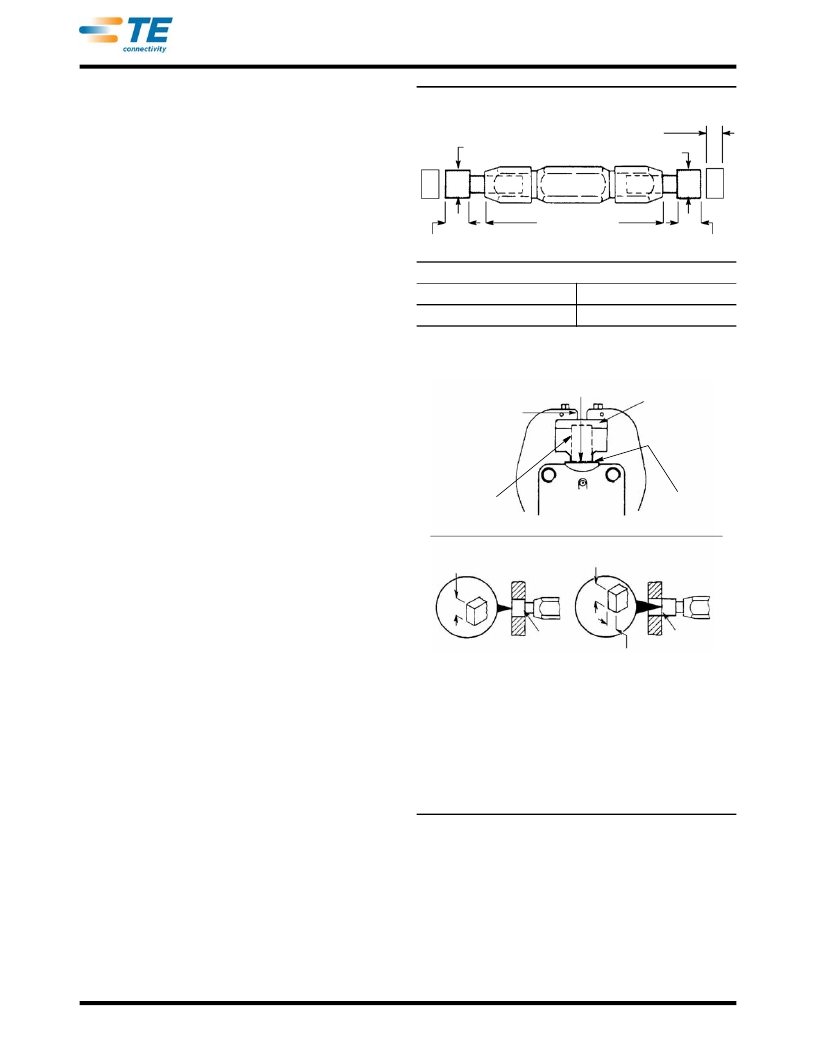

�Suggested� Plug� Gage� Design�

�from� the� tool� with� a� clean� brush� or� a� soft,� lint-free�

�cloth.� Do� NOT� use� objects� that� could� damage� the�

�tool.�

�2.� Make� sure� that� the� proper� retaining� pins� are� in�

�place� and� are� secured� with� the� proper� retaining�

�GO�

�6.35� ±0.25� [.25� ±.01]�

�NO-GO�

�rings.�

�3.� Make� certain� that� all� pins,� pivot� points,� and�

�bearing� surfaces� are� protected� with� a� THIN� coat� of�

�any� good� SAE� 20� motor� oil.� Do� NOT� oil� excessively.�

�4.� When� the� tool� is� not� in� use,� keep� the� handles�

�closed� to� prevent� objects� from� becoming� lodged� in�

�12.7� [.50]�

�63.5� [2.5]� (Typ)�

�GAGE� ELEMENT� DIAMETERS�

�GO� NO-GO�

�12.7� [.50]�

�the� crimping� chambers� and� store� the� tool� in� a� clean,�

�dry� area.�

�15.915-15.920� [.6266-.6268]�

�16.078-16.083� [.6330-.6332]�

�9.2.� Periodic� Inspection�

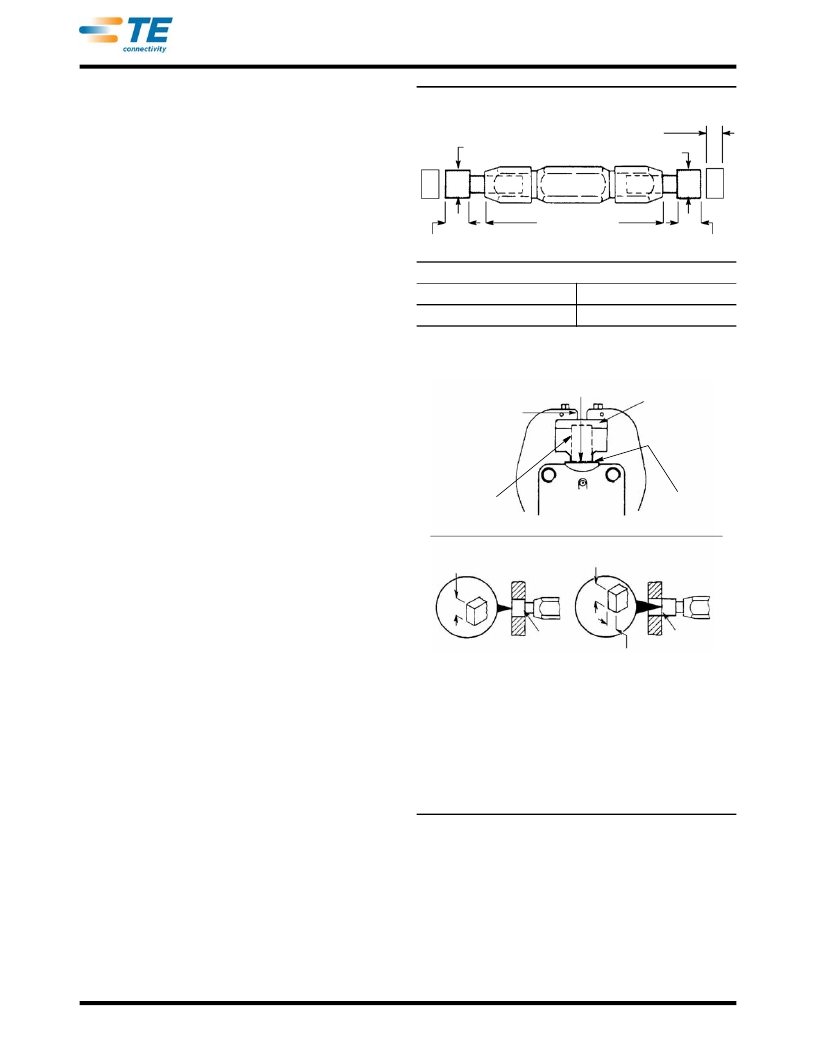

�Inspection� of� Crimping� Chamber�

�Regular� inspections� should� be� performed� by� quality�

�control� personnel.� A� record� of� scheduled� inspections�

�should� remain� with� the� tool� and/or� be� supplied� to�

�supervisory� personnel� responsible� for� the� tool.� Though�

�recommendations� call� for� at� least� one� inspection� per�

�Crimping� Chamber�

�16.0� ±0.08�

�[.630� ±.003]�

�Top� of� Ram�

�Die� Inserts�

�312253-1�

�(Required)�

�month,� the� inspection� frequency� should� be� based� on�

�the� amount� of� use,� working� conditions,� operator�

�training� and� skill,� and� established� company� standards.�

�These� inspections� should� be� performed� in� the�

�following� sequence:�

�A.� Visual� Inspection�

�1.� Remove� all� lubrication� and� accumulated� film� by�

�immersing� the� tool� (handles� partially� closed)� in� a�

�suitable� commercial� degreaser� that� will� not� affect�

�paint� or� plastic� material.�

�GO/NO-GO�

�Gage�

�GO� Element�

�NO-GO� Element�

�Stop�

�Surface�

�2.� Make� certain� that� all� retaining� pins� are� in� place�

�and� are� secured� with� retaining� rings.� If�

�replacements� are� necessary,� refer� to� Section� 10,�

�REPLACEMENT� AND� REPAIR.�

�Crimping�

�Chamber�

�12.2� ±0.25�

�[.48� ±.010]�

�Crimping�

�Chamber�

�3.� Inspect� crimping� chambers� for� pitted� or� chipped�

�surfaces.�

�4.� Close� the� tool� handles� until� the� ratchet� releases,�

�then� allow� handles� to� open� freely.� If� they� do� not�

�open� quickly� and� fully,� the� spring� is� defective� and�

�must� be� replaced.� Refer� to� Section� 10,�

�REPLACEMENT� AND� REPAIR.�

�GO� element� must�

�pass� completely�

�through� the�

�crimping� chamber.�

�NO-GO� element� may�

�enter� partially,� but� must�

�not� pass� completely�

�through� the� crimping�

�chamber.�

�B.� Gaging� the� Crimping� Chambers�

�This� inspection� requires� the� use� of� a� plug� gage�

�conforming� to� the� dimensions� listed� in� Figure� 17.� TE�

�does� not� manufacture� or� market� these� gages.� To� gage�

�the� crimping� chambers,� proceed� as� follows:�

�1.� Insert� Die� Set� 312253-1� as� described� in�

�Section� 5,� TOOL� SETUP.� Do� NOT� insert� the� locator.�

�2.� Close� the� tool� handles� until� the� ram� touches� the�

�stop� surfaces.� Refer� to� Figure� 17.�

�Rev� L�

�Figure� 17�

�3.� Align� the� GO� element� of� the� gage� with� the�

�crimping� chamber� so� that� the� top� and� bottom� of� the�

�gage� align� with� the� surfaces� of� the� die� inserts� and�

�ram.�

�4.� Push� the� element� straight� into� the� crimping�

�chamber� without� using� force.� The� GO� element� must�

�pass� completely� through� the� crimping� chamber� as�

�shown� in� Figure� 17.�

�10� of� 12�

�相关PDF资料 |

PDF描述 |

|---|---|

| 318837-1 | EXTRACTION TOOL .093 CONN |

| 3430-1000 | DISCRETE WIRE INSERTION TOOL |

| 3430-2000 | DISCRETE WIRE HAND TOOL |

| 3430-4000 | HEADER ROLL PIN INSERTER |

| 350-MX23-2 | TOOL CRIMP FOR MX23 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| 31226103 | 制造商:METZ CONNECT USA 功能描述: |

| 31226106 | 制造商:METZ CONNECT USA 功能描述: |

| 31226108 | 制造商:METZ CONNECT USA 功能描述: |

| 31226110 | 制造商:METZ CONNECT USA 功能描述: |

| 31-2264 | 制造商:AMPHENOL 制造商全称:AMPHENOL 功能描述:TNC Jacks |

发布紧急采购,3分钟左右您将得到回复。