- 您现在的位置:买卖IC网 > PDF目录98015 > MJ413 (ON SEMICONDUCTOR) 10 A, 325 V, NPN, Si, POWER TRANSISTOR, TO-204AA PDF资料下载

参数资料

| 型号: | MJ413 |

| 厂商: | ON SEMICONDUCTOR |

| 元件分类: | 功率晶体管 |

| 英文描述: | 10 A, 325 V, NPN, Si, POWER TRANSISTOR, TO-204AA |

| 封装: | METAL, TO-3, 2 PIN |

| 文件页数: | 10/59页 |

| 文件大小: | 356K |

| 代理商: | MJ413 |

第1页第2页第3页第4页第5页第6页第7页第8页第9页当前第10页第11页第12页第13页第14页第15页第16页第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页第37页第38页第39页第40页第41页第42页第43页第44页第45页第46页第47页第48页第49页第50页第51页第52页第53页第54页第55页第56页第57页第58页第59页

4–3

Surface Mount Package Information and Tape and Reel Specifications

Motorola Bipolar Power Transistor Device Data

Prior to placing surface mount components onto a printed

circuit board, solder paste must be applied to the pads.

Solder stencils are used to screen the optimum amount.

These stencils are typically 0.008 inches thick and may be

made of brass or stainless steel. This is not the case with the

DPAK and D2PAK packages. If a 1:1 opening is used to

screen solder onto the drain pad, misalignment and/or “tomb-

stoning” may occur due to an excess of solder. For these two

packages, the opening in the stencil for the paste should be

approximately 50% of the tab area. The opening for the leads

is still a 1:1 registration. Figure 3 shows a typical stencil for

the DPAK and D2PAK packages. The pattern of the opening

in the stencil for the drain pad is not critical as long as it

allows approximately 50% of the pad to be covered with

paste.

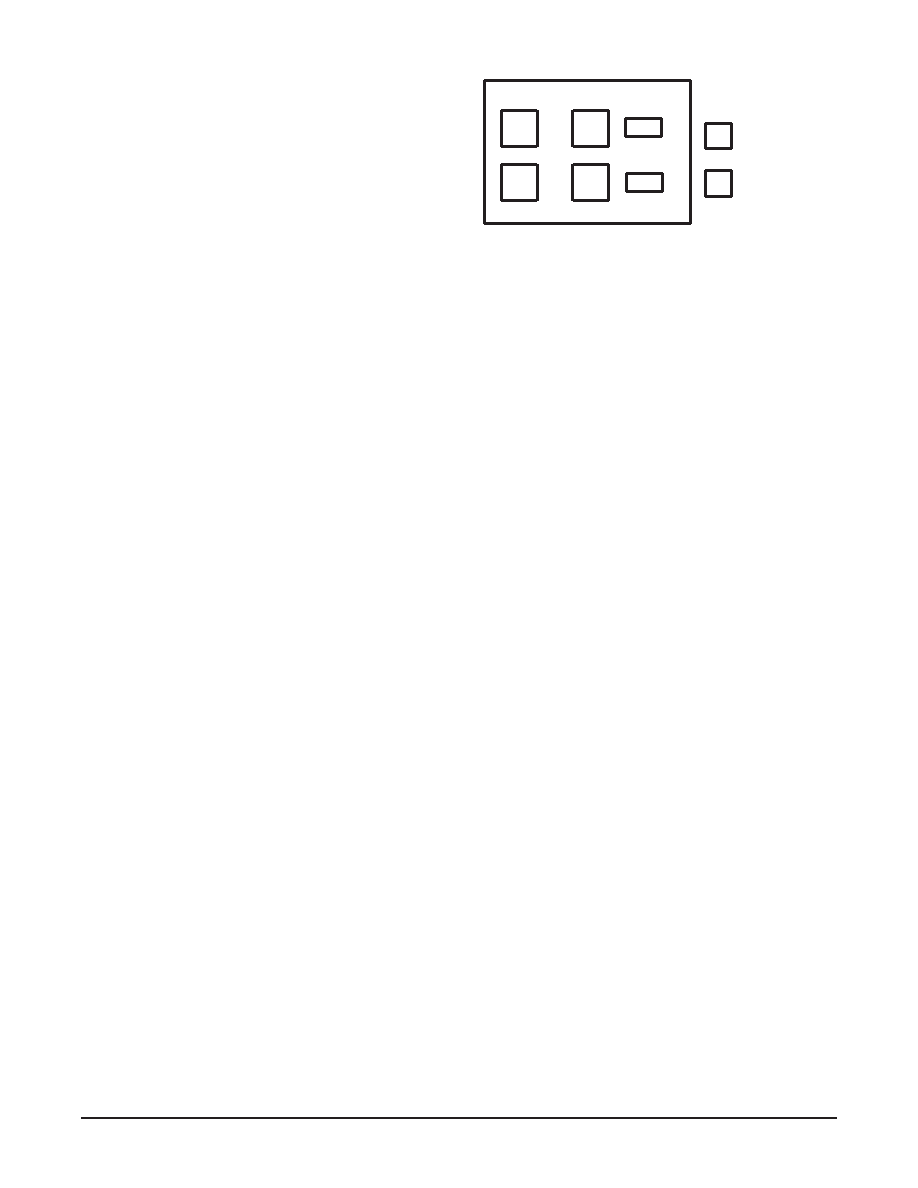

Figure 3. Typical Stencil for DPAK and

D2PAK Packages

SOLDER PASTE

OPENINGS

STENCIL

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short time could result in device failure. Therefore, the

following items should always be observed in order to mini-

mize the thermal stress to which the devices are subjected.

Always preheat the device.

The delta temperature between the preheat and soldering

should be 100

°C or less.*

When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference should be a maximum of 10

°C.

The soldering temperature and time should not exceed

260

°C for more than 10 seconds.

When shifting from preheating to soldering, the maximum

temperature gradient shall be 5

°C or less.

After soldering has been completed, the device should be

allowed to cool naturally for at least three minutes.

Gradual cooling should be used since the use of forced

cooling will increase the temperature gradient and will

result in latent failure due to mechanical stress.

Mechanical stress or shock should not be applied during

cooling.

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.

* Due to shadowing and the inability to set the wave height to

incorporate other surface mount components, the D2PAK is

not recommended for wave soldering.

相关PDF资料 |

PDF描述 |

|---|---|

| MJB18004D2T4 | 5 A, 450 V, NPN, Si, POWER TRANSISTOR |

| MJD127T4 | 8 A, 100 V, PNP, Si, POWER TRANSISTOR, TO-252 |

| MJD122T4 | 8 A, 100 V, NPN, Si, POWER TRANSISTOR, TO-252 |

| MJD13003-I | 1.5 A, 400 V, NPN, Si, POWER TRANSISTOR |

| MJD13003 | 1.5 A, 400 V, NPN, Si, POWER TRANSISTOR |

相关代理商/技术参数 |

参数描述 |

|---|---|

| MJ420 | 制造商:CENTRAL 制造商全称:Central Semiconductor Corp 功能描述:Small Signal Transistors |

| MJ420S | 制造商:CENTRAL 制造商全称:Central Semiconductor Corp 功能描述:Small Signal Transistors |

| MJ421 | 制造商:Motorola Inc 功能描述: |

| MJ421S | 制造商:CENTRAL 制造商全称:Central Semiconductor Corp 功能描述:Small Signal Transistors |

| MJ4221F | 制造商:Ohmite Mfg Co 功能描述: |

发布紧急采购,3分钟左右您将得到回复。