- 您现在的位置:买卖IC网 > PDF目录295335 > CS5165GDWR16 (ON SEMICONDUCTOR) 1.5 A SWITCHING CONTROLLER, 1000 kHz SWITCHING FREQ-MAX, PDSO16 PDF资料下载

参数资料

| 型号: | CS5165GDWR16 |

| 厂商: | ON SEMICONDUCTOR |

| 元件分类: | 稳压器 |

| 英文描述: | 1.5 A SWITCHING CONTROLLER, 1000 kHz SWITCHING FREQ-MAX, PDSO16 |

| 封装: | SOIC-16 |

| 文件页数: | 2/21页 |

| 文件大小: | 718K |

| 代理商: | CS5165GDWR16 |

CS5165

http://onsemi.com

10

APPLICATIONS INFORMATION

THEORY OF OPERATION

V2 Control Method

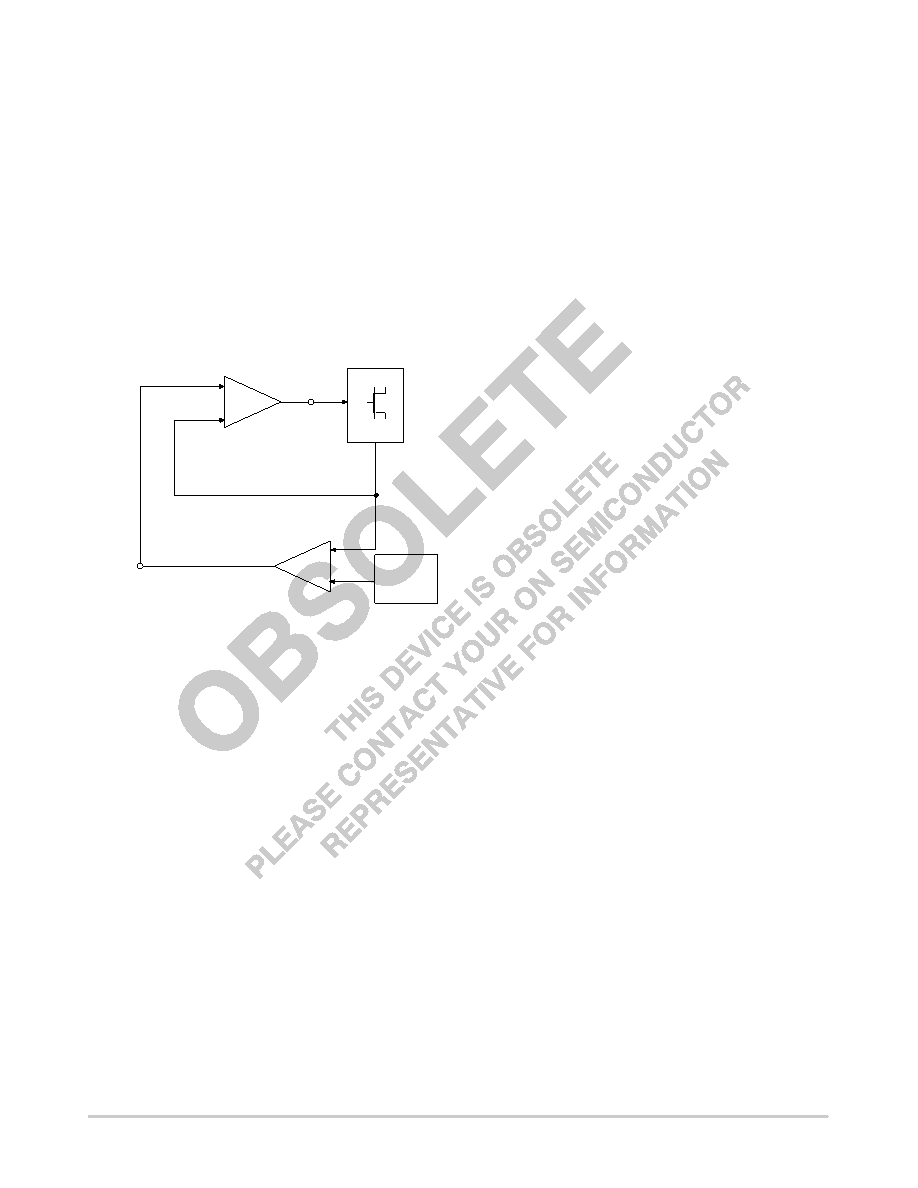

The V2 method of control uses a ramp signal that is

generated by the ESR of the output capacitors. This ramp is

proportional to the AC current through the main inductor

and is offset by the value of the DC output voltage. This

control scheme inherently compensates for variation in

either line or load conditions, since the ramp signal is

generated from the output voltage itself. This control

scheme differs from traditional techniques such as voltage

mode, which generates an artificial ramp, and current mode,

which generates a ramp from inductor current.

Figure 9. V2 Control Diagram

COMP

Reference

Voltage

+

PWM

Comparator

Ramp

Signal

Error

Amplifier

Error

Signal

Output

Voltage

Feedback

GATE(L)

E

C

GATE(H)

output voltage is used to generate both the error signal and

the ramp signal. Since the ramp signal is simply the output

voltage, it is affected by any change in the output regardless

of the origin of that change. The ramp signal also contains

the DC portion of the output voltage, which allows the

control circuit to drive the main switch to 0% or 100% duty

cycle as required.

A change in line voltage changes the current ramp in the

inductor, affecting the ramp signal, which causes the V2

control scheme to compensate the duty cycle. Since the

change in inductor current modifies the ramp signal, as in

current mode control, the V2 control scheme has the same

advantages in line transient response.

A change in load current will have an affect on the output

voltage, altering the ramp signal. A load step immediately

changes the state of the comparator output, which controls

the main switch. Load transient response is determined only

by the comparator response time and the transition speed of

the main switch. The reaction time to an output load step has

no relation to the crossover frequency of the error signal

loop, as in traditional control methods.

The error signal loop can have a low crossover frequency,

since transient response is handled by the ramp signal loop.

The main purpose of this ‘slow’ feedback loop is to provide

DC accuracy. Noise immunity is significantly improved,

since the error amplifier bandwidth can be rolled off at a low

frequency. Enhanced noise immunity improves remote

sensing of the output voltage, since the noise associated with

long feedback traces can be effectively filtered.

Line and load regulation are drastically improved because

there are two independent voltage loops. A voltage mode

controller relies on a change in the error signal to

compensate for a deviation in either line or load voltage.

This change in the error signal causes the output voltage to

change corresponding to the gain of the error amplifier,

which is normally specified as line and load regulation. A

current mode controller maintains fixed error signal under

deviation in the line voltage, since the slope of the ramp

signal changes, but still relies on a change in the error signal

for a deviation in load. The V2 method of control maintains

a fixed error signal for both line and load variation, since the

ramp signal is affected by both line and load.

Constant Off Time

To maximize transient response, the CS5165 uses a

constant off time method to control the rate of output pulses.

During normal operation, the off time of the high side switch

is terminated after a fixed period, set by the COFF capacitor.

To maintain regulation, the V2 control loop varies switch on

time. The PWM comparator monitors the output voltage

ramp, and terminates the switch on time.

Constant off time provides a number of advantages.

Switch duty cycle can be adjusted from 0 to 100% on a pulse

by pulse basis when responding to transient conditions. Both

0% and 100% duty cycle operation can be maintained for

extended periods of time in response to load or line

transients.

PWM

slope

compensation

to

avoid

subharmonic oscillations at high duty cycles is avoided.

Switch on time is limited by an internal 30 μs (typical)

timer, minimizing stress to the power components.

Programmable Output

The CS5165 is designed to provide two methods for

programming the output voltage of the power supply. A five

bit on board digital to analog converter (DAC) is used to

program the output voltage within two different ranges. The

first range is 2.14 V to 3.54 V in 100 mV steps, the second

is 1.34 V to 2.09 V in 50 mV steps, depending on the digital

input code. If all five bits are left open, the CS5165 enters

adjust mode. In adjust mode, the designer can choose any

output voltage by using resistor divider feedback to the VFB

pin, as in traditional controllers. The CS5165 is specifically

designed to meet or exceed Intel’s Pentium II specifications.

相关PDF资料 |

PDF描述 |

|---|---|

| CS5332GDW28 | 1.5 A SWITCHING CONTROLLER, 1000 kHz SWITCHING FREQ-MAX, PDSO28 |

| CS600/L2 | 1 CHANNEL LOGIC OUTPUT OPTOCOUPLER |

| CSBLA384KECE-B0 | CERAMIC RESONATOR, 0.384 MHz |

| CSC5026-0102F | 16 CONTACT(S), COMBINATION LINE CONNECTOR, SOCKET |

| CSD10030 | ZERO RECOVERY RECTIFIER |

相关代理商/技术参数 |

参数描述 |

|---|---|

| CS-5165HDW16 | 制造商:未知厂家 制造商全称:未知厂家 功能描述:Voltage-Mode SMPS Controller |

| CS-5165HDWR16 | 制造商:未知厂家 制造商全称:未知厂家 功能描述:Voltage-Mode SMPS Controller |

| CS5165HGDW16 | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| CS5165HGDWR16 | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| CS5166 | 功能描述:SCREWDRIVER,5/16"X6",SLOTTED 制造商:apex tool group 系列:* 零件状态:在售 标准包装:1 |

发布紧急采购,3分钟左右您将得到回复。