- 您现在的位置:买卖IC网 > PDF目录26800 > MC74AC00DT (ON SEMICONDUCTOR) AC SERIES, QUAD 2-INPUT NAND GATE, PDSO14 PDF资料下载

参数资料

| 型号: | MC74AC00DT |

| 厂商: | ON SEMICONDUCTOR |

| 元件分类: | 门电路 |

| 英文描述: | AC SERIES, QUAD 2-INPUT NAND GATE, PDSO14 |

| 封装: | PLASTIC, TSSOP-14 |

| 文件页数: | 17/45页 |

| 文件大小: | 434K |

| 代理商: | MC74AC00DT |

第1页第2页第3页第4页第5页第6页第7页第8页第9页第10页第11页第12页第13页第14页第15页第16页当前第17页第18页第19页第20页第21页第22页第23页第24页第25页第26页第27页第28页第29页第30页第31页第32页第33页第34页第35页第36页第37页第38页第39页第40页第41页第42页第43页第44页第45页

http://onsemi.com

28

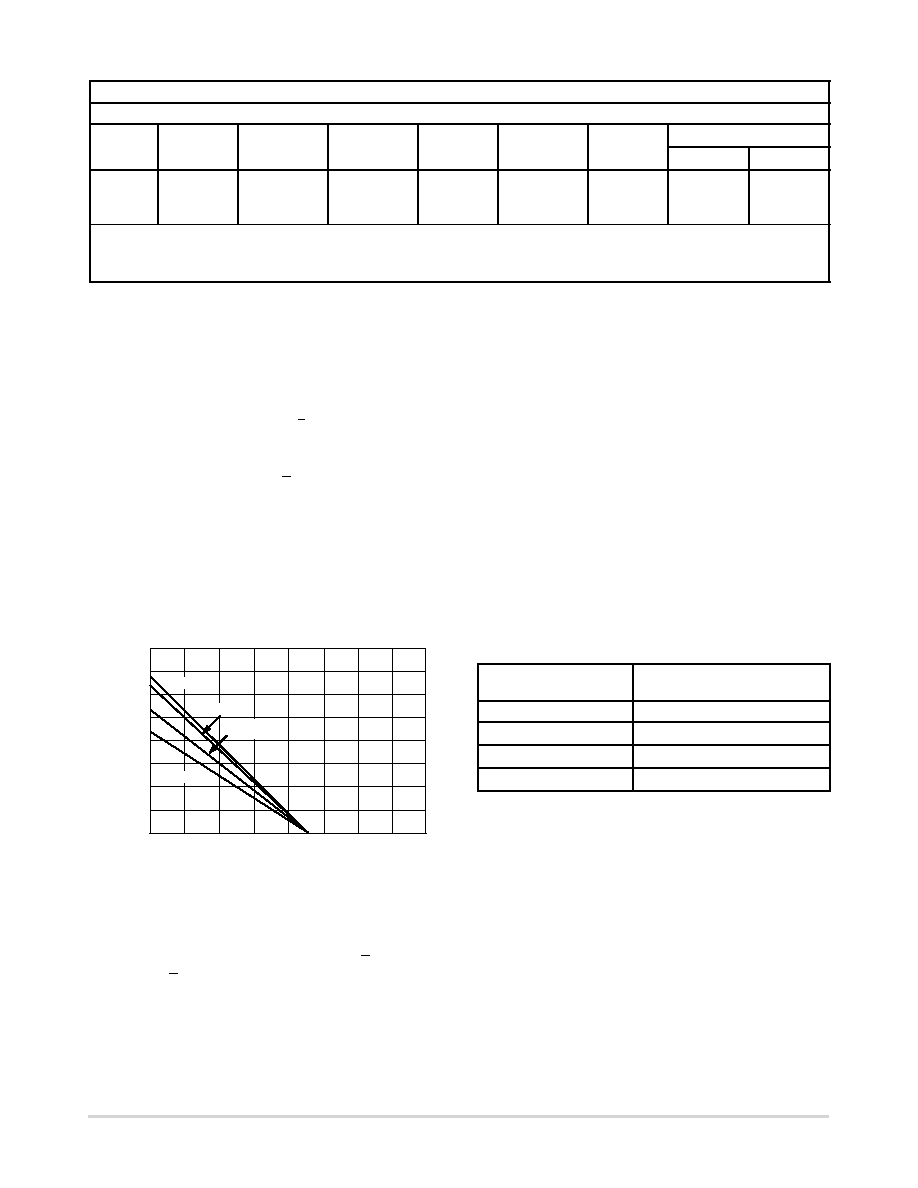

Thermal Resistance In Still Air

Package Description

No

Body

Die

Die Area

Flag Area

θJC (°C/Watt)

No.

Leads

Body

Style

Body

Material

Body

W

× L

Die

Bonds

Die Area

(Sq. Mils)

Flag Area

(Sg. Mils)

Avg.

Max.

14

DIL

Epoxy

1/4

″× 3/4″

Epoxy

4096

6,400

38

61

16

DIL

Epoxy

1/4

″× 3/4″

Epoxy

4096

12,100

34

54

20

DIL

Epoxy

0.35

″× 0.35″

Epoxy

4096

14,400

N/A

NOTES:

1. All plastic packages use copper lead frames.

2. Body style DIL is “Dual-In-Line.”

3. Standard Mounting Method: Dual-In-Line Socket or P/C board with no contact between bottom of package and socket or P/C board.

Figure 1–28. Thermal Resistance Values for Standard I/C Packages

For applications where the case is held at essentially a

fixed temperature by mounting on a large or temperature-

controlled heat sink, the estimated junction temperature is

calculated by:

TJ = TC + PD(θJC)(3)

where TC = maximum case temperature and the other

parameters are as previously defined.

The maximum and average

θJC resistance values for

standard IC packages are given in Figure 1–28. In

Figure 1–29, this basic data is converted into graphs

showing the maximum power dissipation allowable at

various ambient temperatures (still air) for circuits mounted

in the different packages, taking into account the maximum

permissible operating junction temperature for long term

life (

≥ 100,000 hours for ceramic packages).

2000

1750

1500

1250

1000

750

500

250

0

25

50

75

100

125

150

175

200

140

24 LEAD

16 LEAD

14 LEAD

8 LEAD

TA, AMBIENT TEMPERATURE - STILL AIR (°C)

MAXIMUM

ALLOWED

POWER

DISSIP

ATION

(mW/P

k

Figure 1–29. Ambient Temperature Derating Curves

(Plastic Dual-In-Line Package Test Environment)

Air Flow

The effect of air flow over the packages on

θJA (due to a

decrease in

θCA) reduces the temperature rise of the

package, therefore permitting a corresponding increase in

power dissipation without exceeding the maximum

permissible operating junction temperature.

Even though different device types mounted on a printed

circuit board may each have different power dissipations, all

will have the same input and output levels provided that each

is subject to identical air flow and the same ambient air

temperature. This eases design, since the only change in

levels between devices is due to the increase in ambient

temperatures as the air passes over the devices, or

differences in ambient temperature between two devices.

The majority of users employ some form of air-flow

cooling. As air passes over each device on a printed circuit

board, it absorbs heat from each package. This heat gradient

from the first package to the last package is a function of the

air flow rate and individual package dissipations.

Figure 1–30 provides gradient data at power levels of 200

mW, 250 mW, 300 mW, and 400 mW with an air flow rate

of 500 Ifpm. These figures show the proportionate increase

in the junction temperature of each dual in-line package as

the air passes over each device. For higher rates of air flow

the change in junction temperature from package to package

down the airstream will be lower due to greater cooling.

Power Dissipation

(mW)

Junction Temperature Gradient

(

°C/Package)

200

0.4

250

0.5

300

0.63

400

0.88

Devices mounted on 0.062

″ PC board with Z axis spacing of 0.5″.

Air flow is 500 lfpm along the Z axis.

Figure 1–30. Thermal Gradient of Junction

Temperature (16-Pin Dual-In-Line Package)

Optimizing The Long Term Reliability of

Plastic Packages

Todays plastic integrated circuit packages are as reliable

as ceramic packages under most environmental conditions.

However when the ultimate in system reliability is required,

thermal management must be considered as a prime system

design goal.

Modern plastic package assembly technology utilizes

gold wire bonded to aluminum bonding pads throughout the

electronics industry. When exposed to high temperatures for

protracted periods of time an intermetallic compound can

相关PDF资料 |

PDF描述 |

|---|---|

| MC74AC00M | AC SERIES, QUAD 2-INPUT NAND GATE, PDSO14 |

| MC74AC04MR1 | AC SERIES, HEX 1-INPUT INVERT GATE, PDSO14 |

| MC74AC05MR2 | AC SERIES, HEX 1-INPUT INVERT GATE, PDSO14 |

| MC74ACT05DT | ACT SERIES, HEX 1-INPUT INVERT GATE, PDSO14 |

| MC74AC109N | AC SERIES, DUAL POSITIVE EDGE TRIGGERED J-KBAR FLIP-FLOP, COMPLEMENTARY OUTPUT, PDIP16 |

相关代理商/技术参数 |

参数描述 |

|---|---|

| MC74AC00DTR2 | 功能描述:逻辑门 2-6V Quad 2-Input RoHS:否 制造商:Texas Instruments 产品:OR 逻辑系列:LVC 栅极数量:2 线路数量(输入/输出):2 / 1 高电平输出电流:- 16 mA 低电平输出电流:16 mA 传播延迟时间:3.8 ns 电源电压-最大:5.5 V 电源电压-最小:1.65 V 最大工作温度:+ 125 C 安装风格:SMD/SMT 封装 / 箱体:DCU-8 封装:Reel |

| MC74AC00DTR2G | 功能描述:逻辑门 2-6V Quad 2-Input NAND RoHS:否 制造商:Texas Instruments 产品:OR 逻辑系列:LVC 栅极数量:2 线路数量(输入/输出):2 / 1 高电平输出电流:- 16 mA 低电平输出电流:16 mA 传播延迟时间:3.8 ns 电源电压-最大:5.5 V 电源电压-最小:1.65 V 最大工作温度:+ 125 C 安装风格:SMD/SMT 封装 / 箱体:DCU-8 封装:Reel |

| MC74AC00M | 制造商:Rochester Electronics LLC 功能描述:- Bulk |

| MC74AC00MEL | 功能描述:逻辑门 2-6V Quad 2-Input RoHS:否 制造商:Texas Instruments 产品:OR 逻辑系列:LVC 栅极数量:2 线路数量(输入/输出):2 / 1 高电平输出电流:- 16 mA 低电平输出电流:16 mA 传播延迟时间:3.8 ns 电源电压-最大:5.5 V 电源电压-最小:1.65 V 最大工作温度:+ 125 C 安装风格:SMD/SMT 封装 / 箱体:DCU-8 封装:Reel |

| MC74AC00MELG | 功能描述:逻辑门 2-6V Quad 2-Input NAND RoHS:否 制造商:Texas Instruments 产品:OR 逻辑系列:LVC 栅极数量:2 线路数量(输入/输出):2 / 1 高电平输出电流:- 16 mA 低电平输出电流:16 mA 传播延迟时间:3.8 ns 电源电压-最大:5.5 V 电源电压-最小:1.65 V 最大工作温度:+ 125 C 安装风格:SMD/SMT 封装 / 箱体:DCU-8 封装:Reel |

发布紧急采购,3分钟左右您将得到回复。